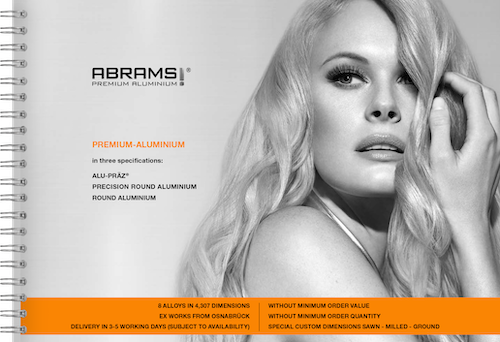

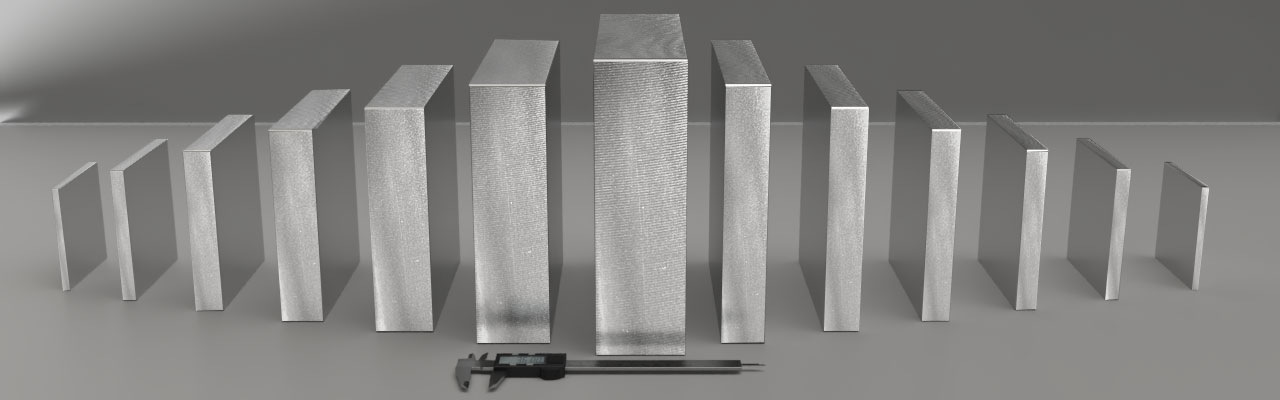

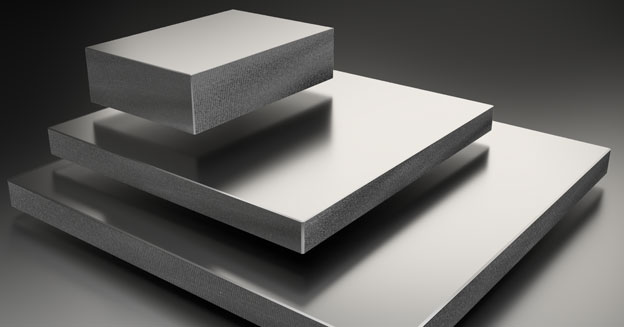

Premium P-Plates from Tool Steel - Precision Plates

P-Plates made from 1.1730 or 1.2312 are Standardised Steel Plates. These standardised P-Plates can be used in a wide variety of applications. For example for mould structures and machine parts to buildings construction.

To guarantee low distortion during further processing the Premium Precision Plates, the primary material is normalised / tempered. Furthermore the thickness of the undrilled Standardised P-Plates is precision ground and the thickness and width are milled to tight toleranzes.

Tolerances

Premium P-Plates [PPP]

For example.: 296,0 x 346,0 x 17,0 mm

W finely milled, Tol. +0,15 / -0 mm

L finely milled, Tol. +0,15 / -0 mm

T ground, Tol. +0,35 / +0,20 mm

Properties of Premium P-Plates

Standardised P-Plates have high wear resistance, toughness and good machinability. Due to its high dimensional accuracy and surface quality, these steel plates are perfectly suited for the production of moulded plates.

Technical Properties of 1.1730 P-Plates

The 1.1730 Premium P-Plates are unalloyed and normalised, have excellent machinabilty and can be used for unhardened components, e.g. fixture construction. Due to its carbon content of 0.45% the standardised plates can be hardened but with a low depth of hardening. These precision plates made from cold work steel can be used as shallow depth case-hardener with a hard surface and tough core.

Working Hardness:

Tensile strength:

(approx. on delivery)

Machinability:

Toughness:

Wear resistance:

Corrosion resistance:

approx. 190 HB (on delivery)

to 54 HRC

approx. 650 N/mm²

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Technical Properties of 1.1730 P-Plates

The 1.1730 Premium P-Plates are unalloyed and normalised, have excellent machinabilty and can be used for unhardened components, e.g. fixture construction. Due to its carbon content of 0.45% the standardised plates can be hardened but with a low depth of hardening. These precision plates made from cold work steel can be used as shallow depth case-hardener with a hard surface and tough core.

Working Hardness:

approx. 190 HB (on delivery)

to 54 HRC

Tensile strength (approx. on delivery):

approx. 650 N/mm²

Machinability:![]()

![]()

![]()

![]()

![]()

![]()

Toughness:![]()

![]()

![]()

![]()

![]()

Wear resistance:![]()

![]()

Corrosion resistance:![]()

![]()

Technical Properties of 1.2312 P-Plates

The 1.2312 P-Plate is a tempered, cold work plastic mould steel with added sulphur which gives this Premium P-Plate its good machinability. The 1.2312 Plates are less polishable and more difficult to edge, due to the added sulphur.

The high through-hardenability of the 1.2312 enables its uniform component strength. There is no distortion as the Precision-Plates do not need to be further heat treated.

Working Hardness:

Tensile strength:

(approx. on delivery)

Machinability:

Toughness:

Wear resistance:

Corrosion resistance:

approx. 32 HRC (on delivery)

to 50 HRC

approx. 1100 N/mm²

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Technical Properties of 1.2312 P-Plates

The 1.2312 P-Plate is a tempered, cold work plastic mould steel with added sulphur which gives this Premium P-Plate its good machinability. The 1.2312 Plates are less polishable and more difficult to edge, due to the added sulphur.

The high through-hardenability of the enables its uniform component strength. There is no distortion as the Precision-Plates do not need to be further heat treated.

Working Hardness:

approx. 32 HRC (on delivery) to 50 HRC

Tensile strength (approx. on delivery):

approx. 1100 N/mm²

Machinability:![]()

![]()

![]()

![]()

![]()

Toughness:![]()

![]()

Wear resistance:![]()

![]()

![]()

Corrosion resistance:![]()

![]()

![]()

What Premium P-Plates are used for?

Precision-Plates are used in a wide variety of applications due to their toughness and easy machinability. Depending on which steel grade, of P-Plates, is being chosen, there are a variety of properties which can be chosen with applications and specific requirments in mind.

Areas of applications for Premium P-Plates

Some of the main areas to use Premium P-Plates:

Mould making

Mould making Gauge making

Gauge making Mechanical engineering

Mechanical engineering Prototype development

Prototype development Punching tool construction

Punching tool construction Fixture construction

Fixture construction Toolmaking

Toolmaking

P-Plates for mould making

P-Plates are often used for the production of plastic moulds. The ability to withstand high temperatures and impact stresses makes them ideal for this application

Die cast moulds

Die cast moulds

Standerdised components

Standerdised components

Standerdised moulds assemblies

Standerdised moulds assemblies

Injection moulds

Injection moulds

P-Plates for toolmaking

Due to its wear resistance and toughness, these P-Plates are ideal for the production of various tools like forming bars and die casting moulds.

Inserts

Inserts Sliders

Sliders Cutting tools

Cutting tools Injection moulding tool

Injection moulding tool Forging Tools

Forging Tools High precision tools

High precision tools Spacer bars for tools

Spacer bars for tools

P-Plates for prototyp development

With a good surface finish, Premium P-Plates are often used for prototyping or small production runs, when a quick and cost effective material processing is required.

P-Plates for special applications

P-Plates can be used in applications that need a combination of high hardness and good machinability and can be applied in the automotive industrie, aviation- and aerospace technology.

P-Plates for mechanical engineering

In the production of machine components P-Plates are used as the “standard material” for machine components like:

Joints

Joints Guides

Guides Machine components

Machine components Fixture components

Fixture components Base plates

Base plates Mould inserts

Mould inserts

1.2312 P-Plates can be used for:

Fixtures

Fixtures Base plates

Base plates Mounting parts

Mounting parts Mould frames

Mould frames Plastic moulds

Plastic moulds Plastic processing

Plastic processing Die casting moulds

Die casting moulds Hydroforming tools

Hydroforming tools Recipient slieves

Recipient slieves Folding bars

Folding bars Tool holders

Tool holders

1.1730 P-Plates are suitable for:

Construction material

Construction material Fixtures

Fixtures Base plates

Base plates Moulded frames

Moulded frames Column frames

Column frames Small moulds

Small moulds Hand tools

Hand tools Simple knives

Simple knives Hammers

Hammers Tongs

Tongs Forks

Forks Hatchets

Hatchets Axes

Axes Scissors

Scissors Screwdrivers

Screwdrivers Chisels

Chisels

ABRAMS® Premium P-Plates

The specification for Premium P-Plates is available in the following Steel Grades: