1.2767 ESR - AT A GLANCE

What kind of steel is the 1.2767 ESR?

1.2767 ESR (ESR = Electro-Slag-Refined or Remelted) has, with the addition of nickel, the ability, even for large cross sections, to be trough-hardened very well. With its high compressive strength this tool steel grade lend itself for stamping or demanding coining tools.

It has high resistance to bending which is an advantage when used for bending inserts. Tool steel 1.2767 ESR is exceptionally suitable to be polished to a mirror finish and therefore is a fitting choice to process plastics that require a high surface finish.

Due to its nickel content, 1.2767 ESR not only has a high hardenability but also a high toughness. The electro-slag remelt process ensures a high level of purity and a homogeneous structure.

Properties

The 1.2767 has a unique combination of wear resistance, toughness and hardness. Those properties make it a great choice for applications which are demanding and use high stress components. To avoid unwanted changes or to reduce risks it is essential to weigh use, properties needed, appropriate heat treatment as well as maintenance carefully.

- Tool steel

- Focus on cold work

- High toughness due to its nickel content

- Good through-hardenability, even for large cross-sections

- Good polishability

- Good etchability

- Good erodibility

- Working hardness is a max. of 54 HRC

- 1.2767 can be used for Damast forging (forge welding)

- Nitiriding is not usually done

- For very special purity and homogeneousness we recommend the 1.2767 ESR

Applications

With its durability, longevity, high hardness and toughness, as well as its resistance to thermal fatigue and cracking, the 1.2767 is suitable for many applications and industries, such as manufacturing, machining, automotive, plastics, toolmaking and medical.

- Cutting tools

- Cutlery punches

- Embossing tools

- Bending tools

- Cold hobbing tools

- Pressure bars

- Billet shear knives

- Cold shear knives

- Plastic molds

- Hot press tools

- Light metal processing

- Heavy metal processing

- Drawing jaws

- Reinforcements

1.2767 ESR STANDARD VALUES

Chemical composition:

| C | Si | Mn | P | S | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|

| 0.4 – 0.5 | 0.1 – 0.4 | 0.2 – 0.5 | 0.0 – 0.03 | 0.0 – 0.03 | 1.2 – 1.5 | 0.15 – 0.35 | 3.8 – 4.3 |

Chemical designation:

45NiCrMo16

Working hardness:

50-54 HRC

Delivery condition:

max. 260 HB

1.2767 ESR PHYSICAL PROPERTIES

What group of steel does the 1.2767 ESR belong to?

- Tool steel

- Plastic mould steel

- Cold work steel

- Hot work steel

Why ESR material?

Electro-slag remelting, also known as electro-flux remelting, is a process by which steel is remelted and passed through a slag that removes debris and impurities from the steel. What remains is a steel with a higher degree of purity and a finer, homogeneous structure. The reduction of impurities in the steel gives it greater integrity, as there are fewer weak points. ESR steel can exhibit better mechanical properties, such as higher tensile strength, yield strength, toughness, wear resistance, better surface finish and longer tool life.

Is the 1.2767 ESR a stainless steel?

To be classified as stainless steel, a steel grade must have a minimum of 10.5% chromium by mass. The 1.2767 ESR has a mass fraction of 1.2 – 1.5% chromium and can therefore oxidise in corrosive or wet environments.

Is the 1.2767 ESR a corrosion resistant steel?

To be corrosion-resistant, 1.2767 ESR has to contain at least 10.5% chromium. Since it only contains 1.2 – 1.5% chromium, it is not considered a corrosion-resistant steel.

Is the 1.2767 ESR magnetisable?

Like most tool steels, 1.2767 ESR consists of iron and carbon. The iron makes the steel grade magnetisable, making it a so-called ferromagnetic steel. Grinding, milling and eroding can be carried out, for example, on machines with magnetic adhesion

1.2767 ESR Cold work

Cold work steels are used for working temperatures of up to 200°C and are suitable for applications such as moulding, cutting tools and cold forming.

1.2767 ESR Wear resistance

The wear resistance of tool steel 1.2767 ESR is rated at 2 on a scale where 1 is low and 6 is high.

1.2767 ESR TECHNICAL PROPERTIES

Is the 1.2767 ESR a knife steel?

Tool steel 1.2767 ESR can be used to make knives because it has the high hardness, wear resistance and toughness required for knife making. Due to its high hardness, it is more difficult to sharpen, and due to its low corrosion resistance, it should be regularly maintained to prevent corrosion.

ESR material has fewer inclusions and its carbides are more evenly distributed, which can potentially give the blade a better finish and a sharper cutting edge.

1.2767 ESR Working hardness

The maximum working hardness for tool steel 1.2767 ESR is 54 HRC.

1.2767 ESR Density

Typically, the density of tool steel 1.2767 ESU 7,85 g/cm3 at room temperature.

1.2767 ESR Machinability

On a scale where 1 is low and 6 is high, the material 1.2767 ESR achieves a 4 for its machinability.

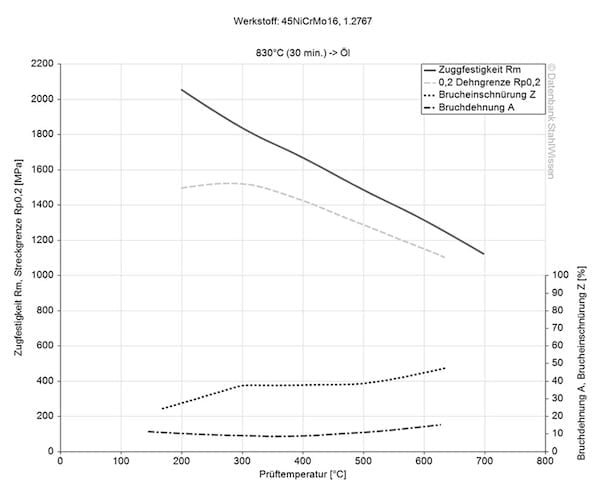

1.2767 ESR Tensile strength

1.2767 ESR has a tensile strength of approx. 880 N/mm2 as-delivered. The tensile strength indicates the maximum load capacity. To obtain this information, a tensile test is carried out to determine how much force is required to elongate or stretch a sample before it breaks.

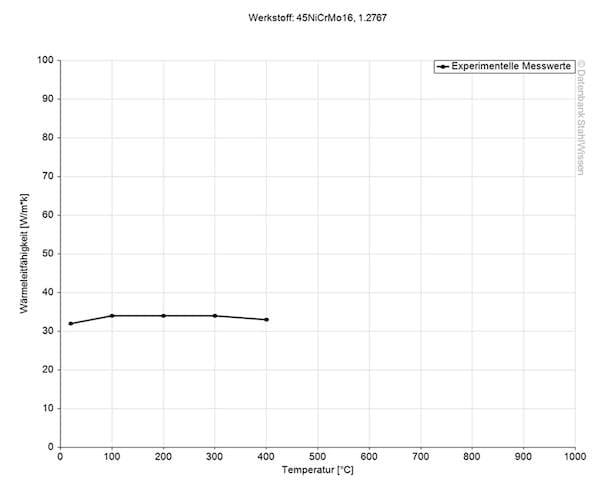

1.2767 ESR Heat conductivity

The following table shows the heat conductivity for the tool steel 1.2767 ESR at various temperatures.

Heat conductivity

Value W/(m*K)

At a temeprature of

31.0

23 °C

34.0

150 °C

33.9

300 °C

34.1

350 °C

33.2

400 °C

31.2

500 °C

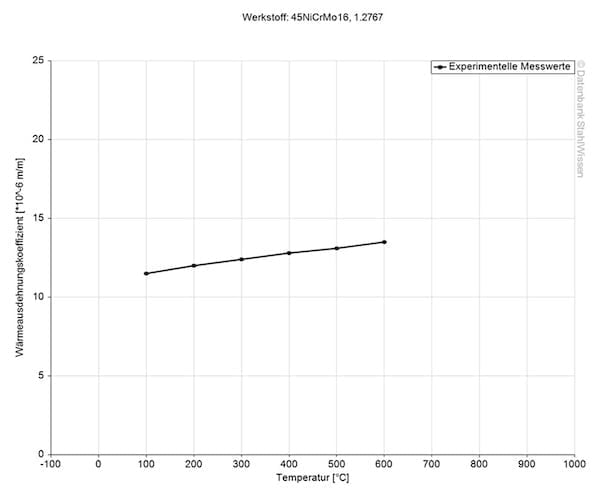

1.2767 ESR Thermal expansion coefficient

The thermal expansion coefficient shows how much a material expands or contracts at any temperature changes. This information can be relevant when when components or parts are exposed to high temperatures or for applications with ever changing temperatures.

Medium thermal expansion coefficient

Value 10-6m/(m*K)

At a temeprature of

11.3

20 – 100 °C

11.9

20 – 200 °C

12.5

20 – 300 °C

12.2

20 – 350 °C

12.0

20 – 400 °C

12.1

20 – 450 °C

12.4

20 – 500 °C

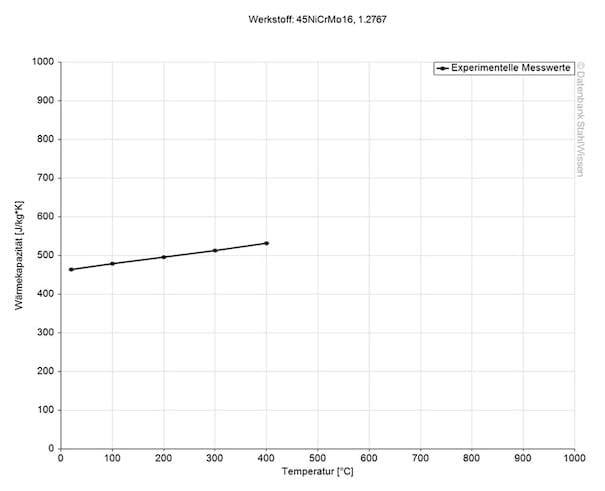

1.2767 ESR Specific heat capacity

The specific heat capacity of tool steel 1.2767 ESR at room temperature is 0,46 J/kg*K. This value shows how much heat is needed to heat a specific amount of material by 1 Kelvin.

1.2767 ESR Specific electrical resistance

The following table shows the specific electrical resistance. Electrical conductivity is the reciprocal of electrical resistivity.

Table of the specific electrical resistivity

Value (Ohm*mm2)/m

At a temperature of

0.3

20 °C

1.2767 ESR Modulus of electricity (Young’s Modulus)

The modulus of electricity or the stress and strain modulus for the 1.2767 ESR is at 210 kN/mm2.

ABRAMS PREMIUM STEEL® –

QUALITY THAT WILL IMPRESS YOU!

1.2767 ESR PRODCEDURE

1.2767 ESR Heat treatment

The heat treatment is used to determine material properties. It should therefore always be carried out with care. Properties such as strength, toughness, surface hardness and temperature resistance are determined, which in turn can extend/improve the service life of parts, tools and components.

The heat treatment process includes solution annealing, soft annealing, normalising, stress relief annealing, but also tempering, hardening and quenching or tempering.

1.2767 ESR Annealing

Heat the 1.2767 ESR material to a uniform temperature of 610–650 °C, hold it there for 2–5 hours, then cool it slowly at a rate of 10–20 °C to approximately 600 °C in the furnace, then continue cooling in air.

1.2767 ESR Stress relieving

After pre-processing, grinding or shaping, the workpieces are heated evenly to a temperature of 650 °C and kept in a neutral atmosphere for 2 hours. Finally, allow the workpieces to cool slowly in the furnace. The uniform and controlled heating and cooling of 1.2767 ESR prevents new thermal stresses and possible dimensional changes.

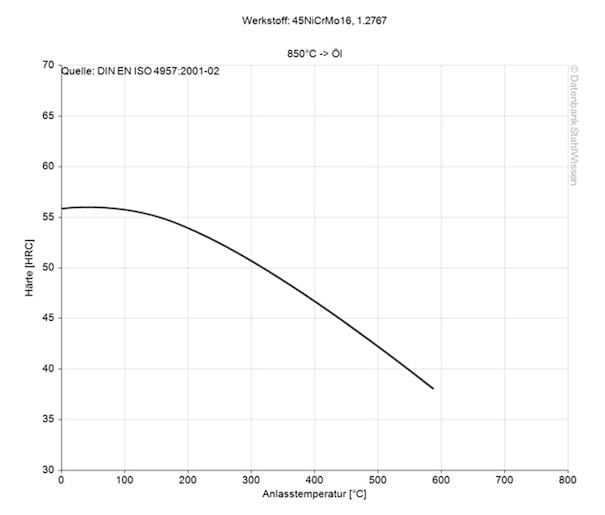

1.2767 ESR Tempering

Immediately after hardening, slowly heat the workpieces to the selected tempering temperature. It is recommended to temper the workpieces twice and allow them to cool to room temperature after each tempering process.

The selected temperature should be maintained for at least 2 hours, or 1 hour per 25 mm thickness.

To avoid undesirable deformation of plastic moulds, the tempering temperature after hardening should be 50 °C higher than the operating temperature.

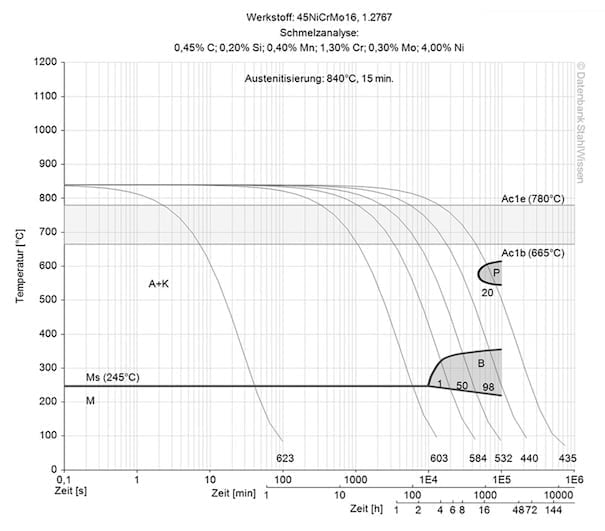

1.2767 ESR Hardening

Heat the 1.2767 ESU material evenly to 650 °C, then increase the temperature to 840 °C and maintain this temperature for 15 to 30 minutes until the temperature is evenly distributed.

1.2767 ESR Quenching

Below are some quenching methods that have been carefully selected taking into account the characteristics and applications they are intended to fulfil.

- Air

- Warm oil (approx. 80 °C)

- Salt bath (300 – 400 °C)

- Gas

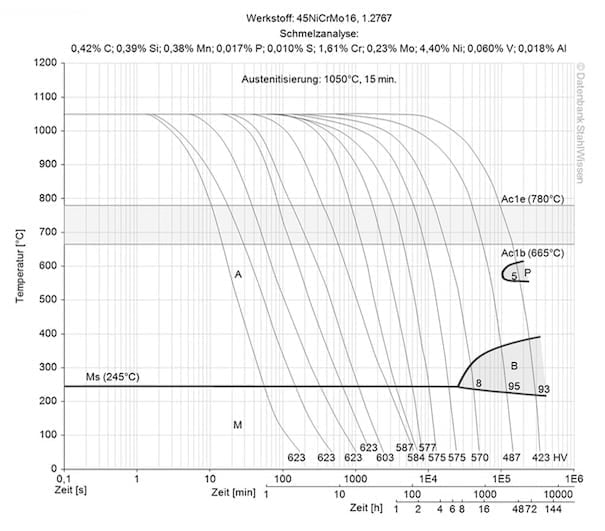

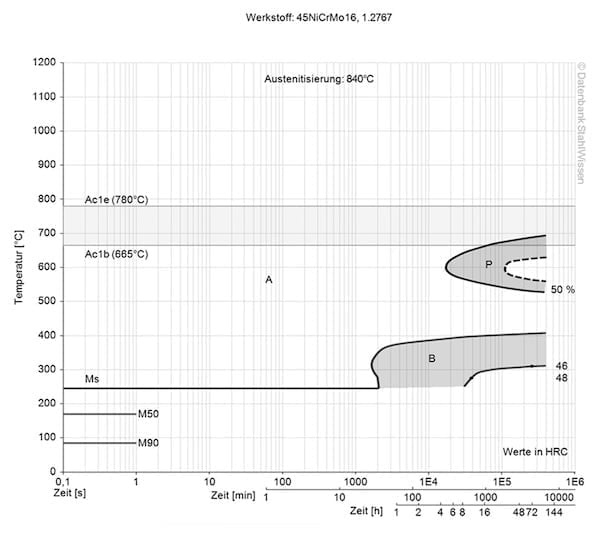

1.2767 ESR Continous TTT-diagram

This diagram shows micro-changes over time at different temperatures. These are important in heat treatment because they provide information about the optimal conditions for processes such as hardening, annealing and normalising.

1.2767 ESR Isothermal TTT-diagram

This diagram shows the structural changes at the micro level over time at a constant temperature. It shows at what temperature and after what time different phases, e.g. perlite, martensite or bainite, begin to form.

1.2767 ESR SURFACE TREATMENT

There are various surface treatments available for 1.2767 ESR tool steel to improve wear resistance, hardness and corrosion resistance. The surface treatment should be chosen carefully, taking into account where and for what purpose the material will be used. Below are some examples of surface treatments for 1.2767 ESR.

1.2767 ESR Nitriding

During nitriding, nitrogen diffuses into the surface of the steel, giving it a harder and more wear-resistant surface. It can improve the service life and corrosion resistance of 1.2767 ESR.

1.2767 ESR Carburising

During carburising, carbon diffuses into the surface of the material, giving the surface high hardness and wear resistance.

1.2767 ESR Carbonitriding

During this process, nitrogen and carbon diffuse into the surface of the metal, giving it greater hardness and wear resistance.

1.2767 ESR Boriding

During boriding, the material surface is coated with a very hard boride layer. This practice is used for tools or components subject to high abrasive wear.

1.2767 ESR Hard chrome plating

During this process, a layer of chrome is applied to the surface of the steel. Chrome plating improves wear and corrosion resistance.

1.2767 ESR Physical Vapor Deposition / Chemical Vapor Deposition

In both processes, the material is coated with a thin, hard layer. The process can increase hardness, improve wear resistance and reduce friction.

1.2767 ESR Polising

This material can be polished to a high gloss.

1.2767 ESR PROCESSING

1.2767 ESR Electrical Discharge Machining (EDM)

EDM is used on workpieces that are manufactured from a single piece, for cutting dies, or for producing complex and delicate shapes and sharp edges. The aforementioned shapes and edges can be achieved by selecting the right EDM process, electrodes and parameters. The recast layer can be completely removed by grinding and polishing.

1.2767 ESR Machining allowance / dimensional changes

Like most metals, this steel grade can contract and expand when heated or cooled. Phase changes, internal stresses and decarburisation can also cause dimensional changes that can affect the properties of this steel grade.

Controlled heating and cooling, stress relief and the avoidance of overheating can reduce the risk of thermal shock and undesirable dimensional changes, such as warping or deformation, but also crack formation, which may mean that a project has to be started all over again.

1.2767 ESR Forging

Heat the material slowly and evenly to a temperature range of 850–1050 °C. Hold the temperature, then slowly cool to 600 °C in the furnace. The 1.2767 ESR can then be left to cool in the air.

1.2767 ESR Welding

Welding of this material grade should be avoided due to cracking and changes in mechanical properties in the weld area. However, if welding is unavoidable, the material should be welded while annealed. Preheating and post-heating treatment is recommended.

1.2767 ESR Grinding

Select the right grinding wheel and use suitable dressing tools to ensure that it is always in good condition.