Toolox 33 - AT A GLANCE

What kind of steel is the Toolox 33?

Toolox 33 comes with a lot of plus points like the very low residual stresses, high impact toughness and crack resistance. Due to the low carbon and alloy content this tool steel is suitable for both welding and thermos-cutting. With the ability to nitrate this material the surface hardness can be additionally increased and service life extended.

The combination of those characteristics makes Toolox 33 suitable for construction and wear parts and other mechanical components as well as plastic and rubber injection molds. It may also be polished and etched with exceptional results.

Properties

The tempered material can optimize the manufacturing process and thus reduce costs. Toolox 33 also has properties such as good wear resistance, good dimensional stability and good machinability, which make machining this material grade a good choice for many applications where precise dimensions and tolerances, durable performance in abrasive environments and a good balance between wear resistance and ease of processing are required.

Practically, this means:

- It is easy to polish

- Grainable

- Erodible

- Etchable

- Autogenous cutting

- Weldable

- Nitridable

- Hard chromium platable

- Working hardness is 30 – 36 HRC

Applications

Thanks to its high strength, good toughness and good mechanical properties the Toolox 33 can be used in a wide variety of industries. Toolox 33 can be used for engineering and tooling due to its wear resistance, durability, dimensional stability (as well under high temperatures) and toughness for moulds, die casting, stamping and forging.

Due to its surface hardness, impact strength and wear resistance it can be used for machine components:

- Ball bearings

- Cylinders

- Pins

- Bushings

The previously mentioned properties make the Toolox 33 to a useful material for:

- Mining equipment

- Wear plates

- Pump parts

- Wind turbines

- Gears

- Armor plates

- Shredder

- For manufaturing agricultural equipment like plough shears

- Mechanical engineering

- Machine parts

- Base plates

- Assembling parts

- Press brake tools

- Plate forming tools

- Wear parts

- Plastic moulds

- Moulding frames

- Rubber moulds

- Die casting moulds

- Guide rails

Toolox 33 Standard values

Chemical composition:

| C | Si | Mn | P | S | Cr | Mo | Ni | V |

|---|---|---|---|---|---|---|---|---|

| 0.22 - 0.24 | 0.6 - 1.1 | 0.8 - 0.8 | 0.0 - 0.01 | 0.0 - 0.003 | 1 - 1.2 | 0.3 - 0.3 | 0.0 - 1 | 0.1 - 0.11 |

Chemical designation:

Toolox 33

Working hardness without nitriding: approx. 30-36 HRC (delivery condition)

Delivery condition:

max. 330 HB

TOOLOX 33 Physical properties

What group of steel does the Toolox 33 belong to?

- Tool steel

- Cold work steel

- Plastic mould steel

Is Toolox 33 a stainless steel?

No, Toolox 33 is not a stainless steel.

Is Toolox 33 corrosion resistant?

Toolox 33 is not corrosion resistant. A steel needs a mass fraction of at least 10,5 % of chromium to be corrosion resistant.

Is Toolox 33 magnetisable?

As a ferrous material, Toolox 33 is magnetisable and therefore suitable for the magnetic clamping technique.

Toolox 33 Cold work

With its combination of high strength, fatigue strength and toughness, Toolox 33 is used in cold forming for shaping, bending and drawing, but is also used in components such as guide plates, support plates and mounting plates.

Toolox 33 Wear resistance

Toolox 33 receives a 3 for its wear resistance on a scale where 1 is low and 6 is high.

TOOLOX 33 Technical properties

Is Toolox 33 a knife steel?

Toolox 33 has good wear resistance, which allows this material to maintain a cutting edge. It has good toughness, which prevents chipping and breaking under stress, and it has been manufactured to have good dimensional stability, which is crucial for maintaining precise tolerances during machining. However, while it has some corrosion resistance, this is not sufficient for use in corrosive environments.

Toolox 33 Working hardness

The working hardness for Toolox 33, in its delivery condition and without nitriding, is 30–36 HRC.

Toolox 33 Density

The density of Toolox 33 tool steel at a temperature of 20 °C is 7.85 g/cm³.

Toolox 33 Tensile strength

The tensile strength of Toolox 33 is approximately 1,125 N/mm². This value is the result of a tensile test that shows how much force is required before the Toolox 33 material begins to stretch or elongate before it breaks.

Toolox 33 Machinability

On a scale where 1 is low and 6 is high, Toolox 33 receives a 4 for its machinability.

Toolox 33 Yield strength

The yield strength indicates how much stress can be applied to Toolox 33 before it undergoes plastic deformation. Beyond this point, the material will not return to its original shape when the stress is removed, but will remain deformed or even break.

The yield strength of Toolox 33 is 850 N/mm2.

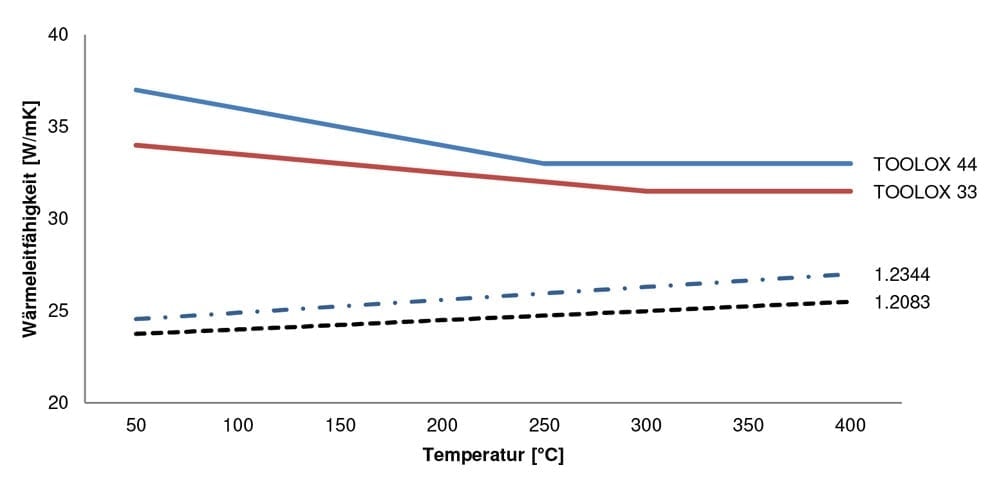

Toolox 33 Heat conductivity

At room temperature the heat conductivity for Toolox 33 is at 35,0 W/(m*K).

Heat conductivity

Value W/(m*K)

At a temperature of

35.0

20 °C

35.0

200 °C

30.0

300 °C

23.0

600 °C

Toolox 33 Thermal expansion coefficient

The coefficient of thermal expansion indicates the expansion or contraction at different temperatures, which can be very important for work at high temperatures or with significant temperature fluctuations. The coefficient of thermal expansion at room temperature for this steel grade is typically approx. 13,1 – 10-6m/(m*K).

MAXIMUM FLEXIBILITY –

THAT IS OUR €co-Präz®!

TOOLOX 33 Procedure

Toolox 33 Heat treatment

No further heat treatment is required for this steel grade, as it is supplied in a tempered condition.

Any further heat treatment of this steel grade should be carefully considered in order to maintain the properties specified by the manufacturer for this grade. In order to maintain these properties, a detailed understanding of metallurgy and how the heat treatment process can alter the properties of Toolox 33 is required.

Toolox 33 Tempering

Toolox 33 is tempered when delivered. The tempering temperature is 590 °C. Tempering removes internal stresses and thus achieves excellent precision during machining.

TOOLOX 33 Surface treatment

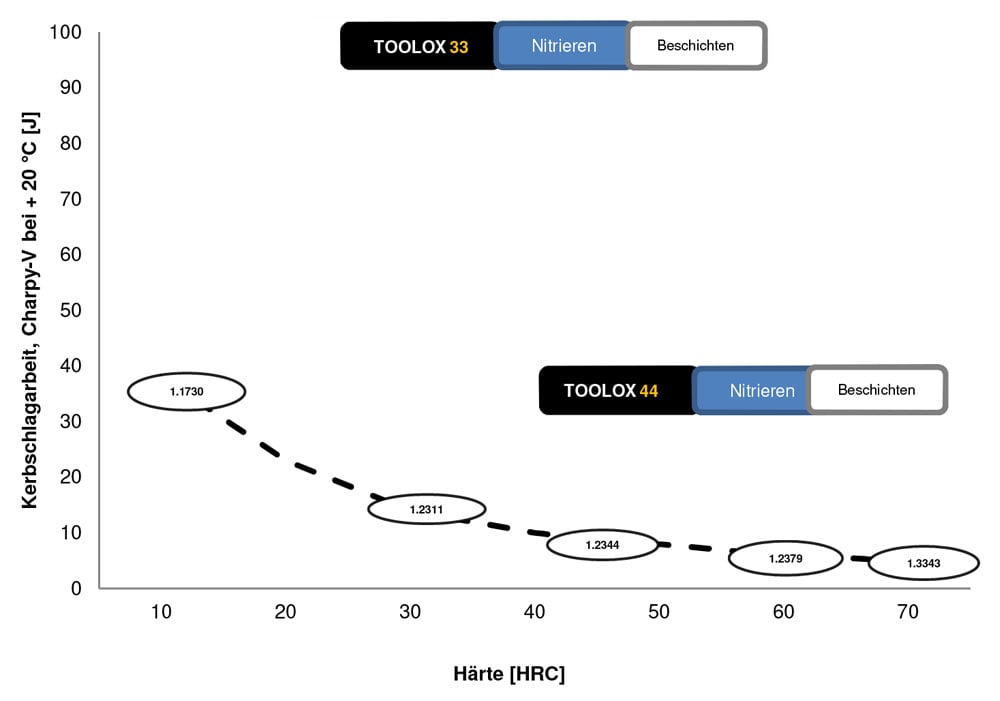

For applications requiring better surface properties, Toolox 33 can be induction or laser hardened and nitrided. This gives Toolox 33 a high surface hardness with a very resistant core, increased fatigue strength and thus a longer service life.

Note:

Any surface treatment should not exceed a temperature of 590 °C.

Toolox 33 Nitriding

Nitriding Toolox 33 can achieve a surface hardness of 58–65 HRC and is used when high wear resistance is required for a longer service life. If the nitrided surface is also coated using the PVD (Physical Vapor Deposition) process, an even higher surface hardness and greater corrosion resistance can be achieved. Using this process, Toolox 33 can achieve a surface hardness of 700 HV and a hardness depth of 0.2 to 2 mm.

Note:

Any surface treatment should not exceed a temperature of 590 °C.

Toolox 33 Induction hardening

Induction hardening, like other surface hardening processes, further improves surface properties. Induction hardening is a very common method of increasing surface hardness.

Toolox 33 Laser hardening

For some applications, the surface properties need to be further improved. In such cases, laser hardening has proven to be a very efficient method. Laser-hardened surfaces have the added advantage of being very smooth, which reduces friction and the risk of material adhering to the surface.

TOOLOX 33 Processing

Toolox 33 Electrical Discharge Machining (EDM)

Choosing the right process, finishing, power input, electrodes and dielectric is important for any steel. Since Toolox 33 is manufactured to obtain specific properties, it is very important that the process is planned and controlled in such a way that the intrinsic properties are retained and the requirements of the intended application are met.

Toolox 33 Dimensional changes

Toolox 33 is designed for dimensional stability after machining, but may still undergo dimensional changes, e.g. during welding as a result of rapid temperature changes.

Toolox 33 Welding

Toolox 33 can be welded using all conventional methods and can be joined to all other weldable steels. Before welding, the base material should be cleaned of contaminants such as grease, rust, oil and moisture, and sharp edges should be removed. Stainless, unalloyed and low-alloy welding consumables are suitable for use with Toolox 33.