HSS PM 30 - AT A GLANCE

What kind of steel is the HSS PM 30?

The high speed steel 1.3294, also known as HSS PM 30, is a powder metallurgical high-speed steel that can be used for cold work and cutting tools. It is characterised by high wear resistance, excellent cutting edge retention, high compressive strength and thermal resistance. The cobalt addition of approx. 8.5% has a positive effect on high-temperature strength and hardness, tempering resistance and the modulus of elasticity. However, the cobalt addition slightly reduces toughness and depth of hardening.

Properties

As a powder metallurgically produced high speed steel the HSS PM 30 combines an excepional hardness, wear resistance and toughness. Due to these properties, it can be used in a wide range of industries. Its fine-grained and homogeneous structure make it an excellent choice when high performance, long tool life, precision and reliability are required

- High-performance high-speed steel

- Powder-metallurgical production

- High wear resistance

- Excellent cutting edge retention

- High-temperature strength (red hardness) due to the addition of approx. 8.5% cobalt

- Good tempering resistance

- Fine, homogeneous microstructure

Applications

With its high hardness, toughness and temperatur resistance the HSS PM 30 can be used over many industries and in many applications. With a finely grained and homogeneous microstructure this steel grade has better mechanical properties, performance and service life.

- Machining tools

- Milling cutters

- Thread cutting tools for materials that are difficult to machine

- Fine-blanking tools

- Drills

- Broaches

- Forming tools

- Blanking tools

- Deep drawing tools

- Die sets

HSS PM 30 Standard values

Chemical composition:

| C | Cr | Mo | V | W | Co |

|---|---|---|---|---|---|

| 1.3 - 1.3 | 4.2 - 4.2 | 5.0 - 5.0 | 3.1 - 3.1 | 6.4 - 6.4 | 8.5 - 8.5 |

Chemical designation:

PMHS6-5-3-8

Working hardness:

60-66 HRC

Delivery condition:

max. 300 HB

HSS PM 30 Physical properties

What group of steel does the HSS PM 30 belong to?

- High speed steel

- Plastic mould steel

- Cold work steel

- Hot work steel

Is the HSS PM 30 a stainless steel?

To be classified as classic stainless steel, a steel grade must contain at least 10.5 % chromium. PM 30 has a mass fraction of 4.2 % and is therefore not a classic stainless steel.

Is the HSS PM 30 corrosion resistant?

With a mass fraction of 4.2 % of chromium, PM 30 does have a certain degree of corrosion resistance, but this is not sufficient to make it suitable for corrosive environments. Corrosion resistance can be improved by coating the material, limiting exposure time, and implementing good maintenance routines and storage practices.

Is the HSS PM 30 magnetisable?

The 1.3294 / PM 30 is a ferromagnetic material that can be magnetised and can be used with the magnetic clamping technology.

HSS PM 30 Cold work

PM 30 high-speed steel offers a good combination of high wear resistance and high compressive strength, making this material suitable for cold working.

HSS PM 30 Wear resistance

The HSS PM 30 scores a 6 for wear resistance on a scale where 1 is low and 6 is high.

HSS PM 30 Technical properties

Is the HSS PM 30 a knife steel

PM 30 has several excellent properties that make it suitable for knife production. Its outstanding wear resistance, good toughness, high hardness and fine structure result in knives that stay sharp for a long time and do not break. However, they are not corrosion resistant, which means that caution is required in damp and acidic environments. Although its hardness is an advantage in terms of cutting performance, it makes PM 30 knives difficult to sharpen and unsuitable for applications that require extreme flexibility and impact resistance.

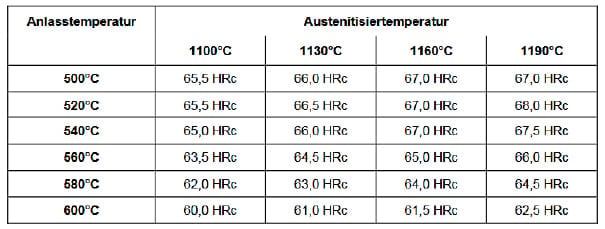

HSS PM 30 Working hardness

The working hardness of the HSS PM 30 is at 60 – 66 HRC.

HSS PM 30 Density

At room temperature, the typical density of High Speed Steel PM 30 is 8.04 g/cm3.

HSS PM 30 Tensile strength

PM 30 has a tensile strength of approx. 995 N/mm² upon delivery. To achieve this value, a tensile test is carried out to show how much force is required to stretch or elongate a sample before it breaks.

HSS PM 30 Machinability

On a scale where 1 is low and 6 is high, 1.3294 (HSS PM 30) receives a 2 for its machinability.

HSS PM 30 Heat conductivity

The thermal conductivity of 1.3294 high-speed steel is 24.4 W/(m*K) at a temperature of 20 °C.

Heat conductivity

Value W/(m*K)

At a temperature of

24.4

20 °C

28.0

350 °C

27.4

700 °C

HSS PM 30 Thermal expansion coefficient

The following table shows the expansion and contraction of the material at various temperatures which is imortant information when working with high temperatures or when there are significant temperature fluctuations during use.

Medium thermal expansion coefficient

Value 10-6m/(m*K)

At a temeprature of

10.9

20 – 100 °C

11.1

20 – 200 °C

11.4

20 – 300 °C

11.5

20 – 400 °C

HSS PM 30 Specific heat capacity

At room temperature the specific heat capacity for the PM 30 is at 0,42 J/kg*K. This value shows how much heat is needed to heat a specific amount of material by 1 Kelvin.

USE UP TO 40% LESS MATERIAL = LESS WASTE – THAT IS OUR €co-Präz®!

HSS PM 30 Procedure

HSS PM 30 Heat treatment

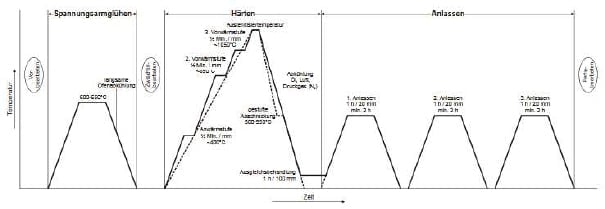

The heat treatment process determines the material properties. It should therefore always be carried out with care. Properties such as strength, toughness, surface hardness and temperature resistance are determined, which in turn can extend/improve the service life of parts, tools and components.

Heat treatment includes solution annealing, soft annealing, normalising and stress relief annealing, as well as tempering, hardening and quenching or tempering.

HSS PM 30 Annealing

The workpiece is heated evenly to a temperature of 850–900 °C, held at this temperature for 2 hours, and then slowly cooled in the furnace at a rate of 10 °C per hour to a temperature of 700 °C. Finally, the material can be left to cool further in air.

HSS PM 30 Stress relieving

For stress relieving, the PM 30 is heated to a temperature of 600 – 700 °C and held there for 2 hours. The workpiece is then slowly cooled in the furnace to approx. 500 °C. The workpiece can then be further cooled in air.

HSS PM 30 Hardening

It is recommended to harden 1.3294 steel in a salt bath, a vacuum furnace or in a controlled atmosphere.

Preheat HSS PM30 evenly to 450 – 500 °C and then further to 850 – 900 °C, then raise the temperature to a range of 1050–1180 °C and hold briefly depending on the selected working hardness, avoiding overheating and protecting the material from decarburisation or oxidation.

HSS PM 30 Quenching

After hardening, PM 30 can be quenched in the following media:

- Air

- Oil

- Compressed gas (N2)

- Water bath (500 – 550 °C)

HSS PM 30 Tempering

The PM 30 is tempered three times, with the material being cooled to room temperature between each tempering process. The holding time is one hour per tempering process. If the material is used for cold working, the tempering temperature must always be 560 °C, regardless of the austenitising temperature.

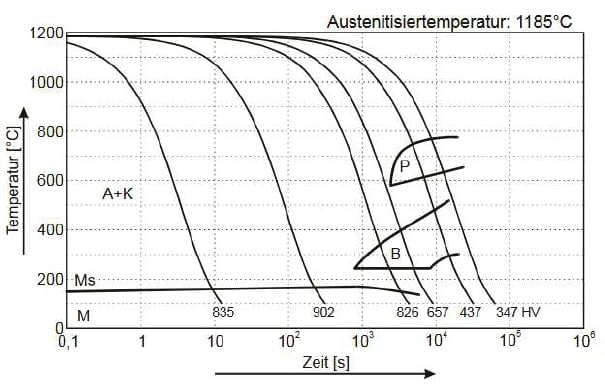

HSS PM 30 Continuous TTT diagram

This diagram shows micro-changes over time at different temperatures. These are important in heat treatment, as they provide information about the optimal conditions for processes such as hardening, annealing and normalising.

HSS PM 30 Surface treatment

Each surface treatment has its own advantages and should be selected taking into account the required properties, the desired finish and/or the environment in which the workpiece is to be used. Here are some examples of surface treatments:

HSS PM 30 Nitriding

Nitriding increases the surface hardness and wear resistance of tools and components by diffusing nitrogen intro the surface of the material. Nitriding maintains dimensional and is often usedfor components where dimensional stability is very important.

HSS PM 30 Coating

Coating can increase the wear resistance and corrosion resistance for the PM 30 and reduce friction. This methode is usually used for cutting tools or drills.

HSS PM 30 PVD and CVD coating

During both processes a thin protective layer is applied to the surface of the material which can increase hardness and wear resistance and decrease friction.

- PVD – physical vapour deposition

- CVD – chemical vapour deposition

HSS PM 30 Processing

HSS PM 30 Electrical Discharge Machining (EDM)

As a non-contact, thermal energy-based machining process, EDM can be used for hard materials such as HSS PM 30. Electrodes, surface finish and heat-affected zones should be considered before using EDM for PM 30 material.

Heat-affected zones may need to be further heat treated after EDM to equalise the structure in the workpiece. EDM can leave a rough surface with a recast layer, which can be removed by grinding and polishing.

HSS PM 30 Machining allowance / dimensional changes

As with other steels, PM 30 also undergoes dimensional changes during heating and cooling. To reduce dimensional changes such as warping or deformation, it is important to control the heating and cooling rates or to use fixtures that hold the material in place. It is always important to take these changes into account by allowing for a tolerance in the material and heating or cooling in a controlled manner when precise dimensions are required.

HSS PM 30 Grinding

Localised heat on the surface should be avoided during grinding, as it can alter the surface condition of the workpiece.

HSS PM 30 Welding

To reduce stress, 1.3294 (PM 30) is preheated evenly before welding. This minimises the risk of cracking. A suitable welding process allows good control of the heat input and enables precise work. Welding consumables should be selected so that they are compatible with the base material and match its properties. To restore the mechanical properties, workpieces should be post-treated with heat treatment. Finally, the weld seam should be carefully inspected to detect any cracks or other damage before the workpiece is used. The final inspection guarantees the integrity and performance of the workpiece.