1.4006 - AT A GLANCE

What kind of steel is the 1.4006?

Stainless steel 1.4006, here in its tempered condition, is machinable and can be used for applications needing high strength, medium heat- and corrosion resistance.

As a martensitic stainless steel it has less corrosion resistance than an austenitic stainless steel, and its useful operating temperature range is limited by loss of ductility at temperatures below zero and loss of strength due to over-tempering at higher temperatures as well as further reducing its corrosion resistance.

The corrosion resistance of this steel grade can be improved by polishing the surface and by hardening and tempering.

Properties

Stainless steel 1.4006 can be characterised by a balanced of hardness, corrosion resistance and high mechanical strength.

Specifically this means:

- Hardenable , can reach high hardness

- High strength

- Medium heat- and corrosion resistance

- Magnetisable

- Stainless

- Highly polishable

- Limited acid resistance

- Nitridable

- EDM machinable

- Working hardness at approx. 25 – 31 HRC

Applications

Hydraulic engineering, mechanical engineering, pump industry, oil industry, petrochemical industry, decorative uses, kitchen equipment, food industry, environmental technology, energy technology (hydroelectrical power).

As a martensitic stainless steel, not as corrosion resistant as an austenitic steel, this steel grade has a good corrosion resistance.

- Cutlery

- Surgical instruments

- Valve parts

- Pump shafts

- Ball bearings

- machine parts

- Mine ladder rungs

- Bolts

- Bushings

- Screws

- Nuts

1.4006 Standard values

Chemical composition:

| C | Si | Mn | P | S | Cr | Ni |

|---|---|---|---|---|---|---|

| 0.08 - 0.15 | 0.0 - 1.0 | 0.0 - 1.5 | 0.0 - 0.04 | 0.0 - 0.03 | 11.5 - 13.5 | 0.0 - 0.75 |

Chemical designation:

X12Cr13

Working hardness: approx. 25 HRC (delivery condition) up to 31 HRC

Delivery condition:

max. 252 HB

1.4006 Physical properties

What group of steel does the 1.4006 belong to?

- Martensitc stainless steel

- Stainless steel corrosion resistant

- Stainless steel acid resistant

- Stainless steel

- Hot work steel

Is the 1.4006 a stainless steel?

Yes with a mass fraction of 11,5 – 13,5 % of chromium the 1.4006 is a stainless steel.

Is the 1.4006 stainless steel corrosion resistant?

Stainless steel 1.4006 has good resistance to atmospheric conditions, fresh water, foods, mild alkalis and acids, hot gases, dry and oxidising atmospheres up to temperatures of around 600 °C. A smooth polished surface can provide additional protection.

1.4006 Hot work

1.4006 stainless steel is magnetisable and magnetic in both annealed and heat-treated states and suitable for magnetic clamping technology.

1.4006 Warmarbeit

This process is carried out at a temperature of 750–1150 °C and teh material is then cooled in air. If smaller sheets are being formed, the material should be preheated to 100–300 °C. More severe forming should be followed by annealing or stress relieving at a temperature of 650 °C.

1.4006 Cold work

In its annealed condition the 1.4006 can be moderately cold formed.

1.4006 Wear resistance

This stainless steel receives a 2 for its wear resistance on a scale where 1 is low and 6 is high.

1.4006 Technical properties

Is the 1.4006 a knife steel?

Stainless steel 1.4006 can be used for the manufacture of knives. Although it has good corrosion resistance, its low carbon content means that it does not retain its sharpness for very long. 1.4006 has good toughness when the priority is to prevent chipping and breakage. In general, 1.4006 can be used for lower-priced knives when corrosion resistance and toughness are important and cutting performance is less important.

1.4006 Working hardness

The working hardness of stainless steel 1.4006 is in the range of 25 – 31 HRC.

1.4006 Density

The typical density of stainless steel 1.4006 is 7.8 g/cm3 at room temperature.

1.4006 Tensile strength

1.4006 has a tensile strength of approx. 850 N/mm2. To achieve this value, a tensile test is carried out to show how much force is required to stretch or elongate a sample before it breaks.

1.4006 Machinability

This grade is easy to machine when annealed or tempered. It is not recommended to machine this material when hardened to more than 30 HRC, as machining becomes challenging.

1.4006 Yield strength

The yield strength indicates how much stress can be applied before a material undergoes plastic deformation. Beyond this point, the material does not return to its original shape when the stress is removed, but remains deformed or even breaks. The yield strength for stainless steel 1.4006 is 178 N/mm2.

1.4006 Heat conductivity

The thermal conductivity of stainless steel 1.4006 is 30 W/(m*K) at room temperature.

1.4006 Thermal expansion coefficient

The following table shows the expansion or contraction at different temperatures, which can be very important for work at high temperatures or with significant temperature fluctuations.

Medium thermal expansion coefficient

Value 10-6m/(m*K)

At a temperature of

10.5

20 – 100 °C

11.0

20 – 200 °C

11.5

20 – 300 °C

12.0

20 – 400 °C

1.4006 Specific heat capacity

The specific heat capacity of stainless steel 1.4006 at room temperature is 0.46 J/kg*K. This value indicates how much heat is required to heat a specific amount of material by 1 Kelvin.

1.4006 Specific electrical resistance

The following table shows the specific electrical resistance of stainless steel 1.4006. Electrical conductivity is the reciprocal of specific resistance.

Specific electrical resistivity

Value (Ohm*mm2)/m

At a temperature of

0.60

20 °C

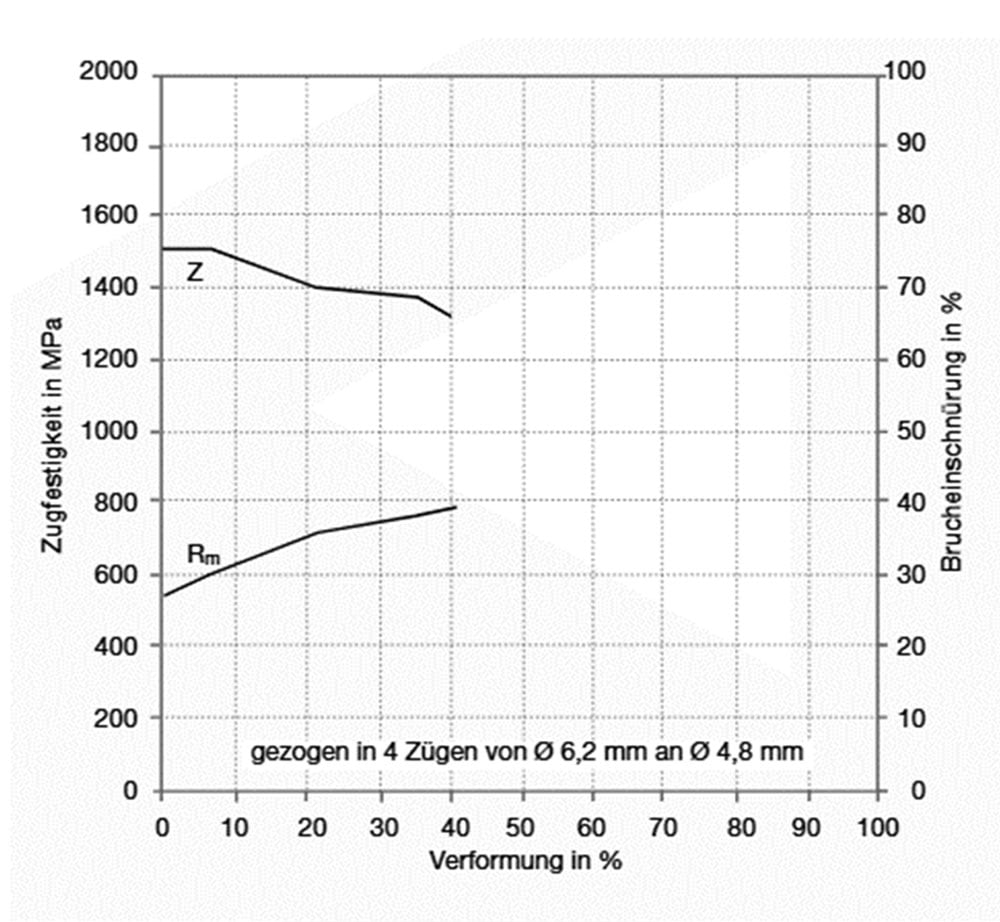

1.4006 Compression diagram

ORDER THE SMALLEST AMOUNT - WITHOUT A MINIMUM ORDER VALUE!

1.4006 Procedure

1.4006 Heat treatment

Stainless steel 1.4006 has good scale resistance at a continuous temperature of 649 °C and with sporadic heating up to a temperature of 816 °C.

1.4006 Annealing

The 1.4006 should be heated through to a temperature 816 – 899 °C to annealing this material. This is followed by cooling it to a temperature of 593 °C in the furnace which is followed by further cooling down in air.

1.4006 Process annealing

Heat the work pieces to a temperature of 732 – 788 °C and then let them cool in air.

1.4006 Stress relieving

Heat the material to a temperature of 149 – 427 °C and hold it for 1 – 2 hours bevor finishing this process of by cooling it in air.

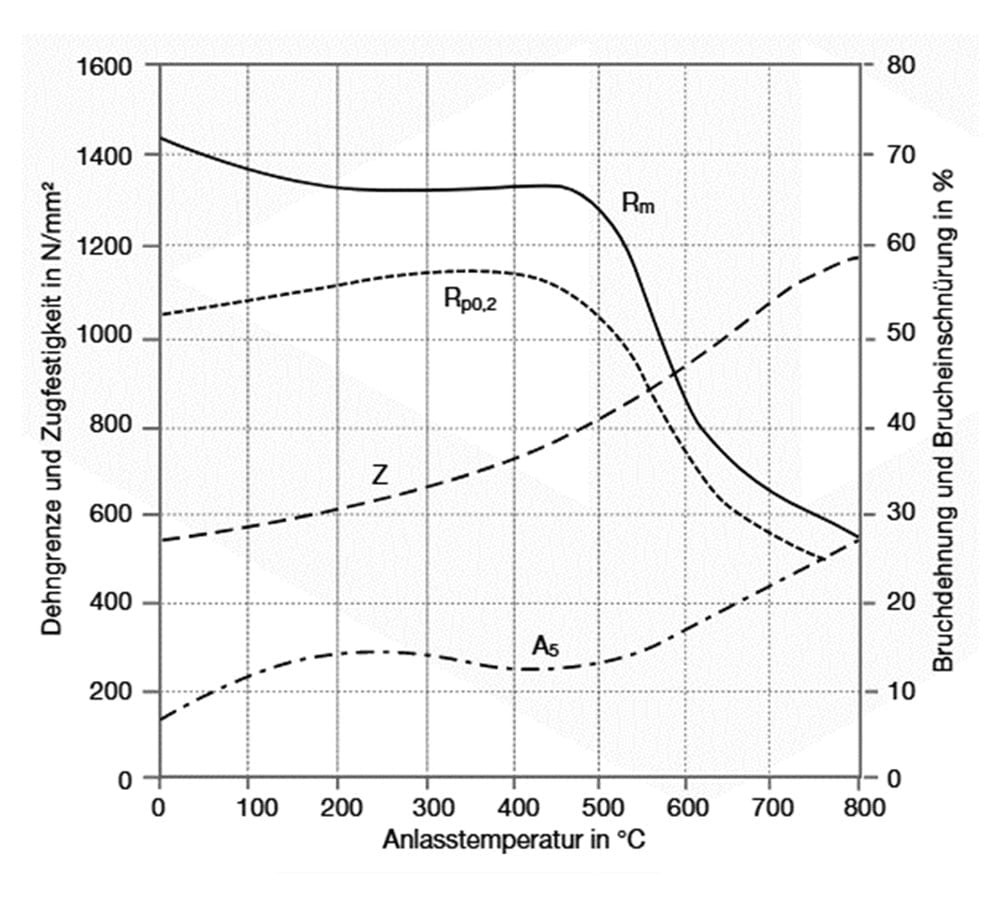

1.4006 Tempering

Heat the 1.4006 to a temperature of 593 – 760 °C and hold it for 1 – 4 hours and after cool it in air. The temperature and holding time depend on the mechanical properties are needed.

Tempering the 1.4006 will give it a better toughness and reduces the brittelness that can happen when quenching it.

1.4006 Hardening

Heat the 1.4006 evenly to a temperature of 927 – 110 °C followed by cooling in air or quenching in oil. The material should be stress relieved or tempered to finish this process.

1.4006 Quenching

This grade of steel must be quenched quickly to achieve hardening.

- Air: Blown air is used for more complex or thinner parts, or when the quenching speed is not so important.

- Oil: A common method for martensitic steel. Oil removes heat from the workpieces and cools them down. It can be preheated, which allows for more uniform quenching.

- Water/water polymer mixture: These quenching agents are used when higher hardness is desired. Caution is advised, as these media can lead to higher stresses and thus to cracking.

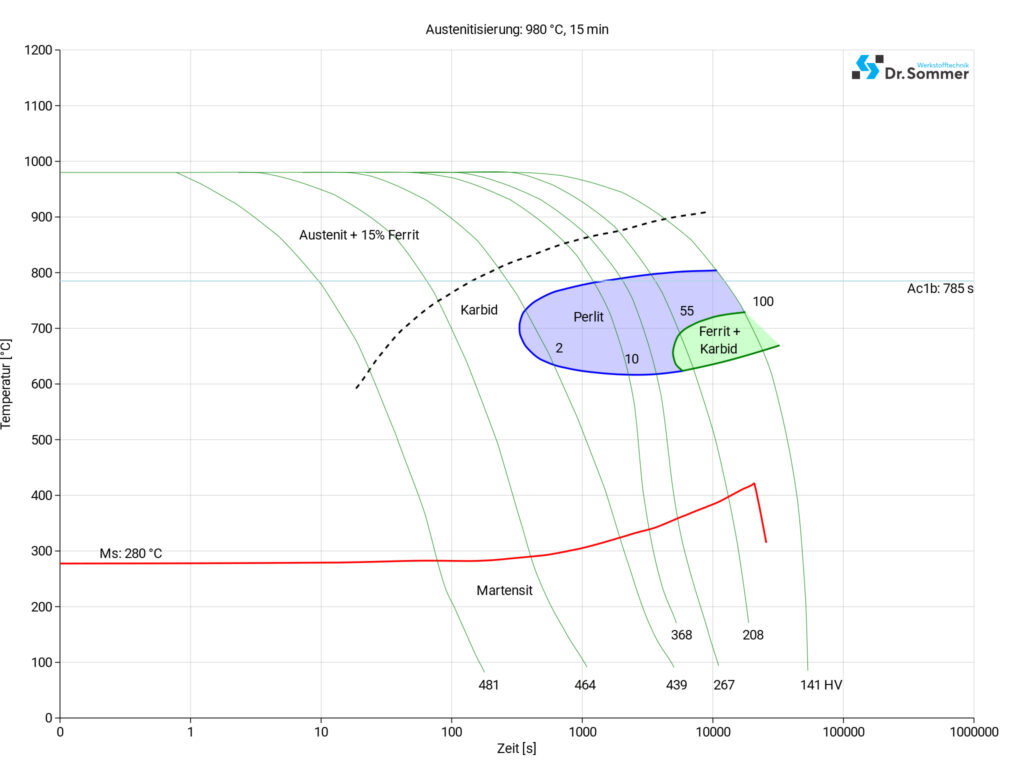

1.4006 Continuous TTT-Diagram

The TTT-diagram usually shows micro-changes over time at different temperature. These are important in heat treatment as they provide information on the optimal conditions for processes such as hardening, annealing and normalising.

1.4006 Surface treatment

1.4006 Nitriding

Nitriding can increase the natural corrosion resistance by diffusing nitrogen into the surface. This process can also improve its wear resistance.

1.4006 Passivation

Passivation removes free ironfrom the surface by treating the surface with an acid solution like citric or nitric acid. Passivation creates a protective oxide layer that increases the corrosion resistance of this material.

1.4006 Electropolishing

Electropolishing is a non-mechanical chemical process in which a thin layer of material is removed using an electric current to give the material a smooth and shiny surface and minimise the adhesion of bacteria, which can be beneficial in medical devices and/or food processing equipment.

1.4006 Bead blasting

Abrasive particles such as glass or ceramic beads are blasted onto the surface to remove contaminants such as rust, paint or scale and achieve a uniform matt finish.

1.4006 PVD and CVD coating

Both processes, PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition), apply a thin layer to the surface of the material. This thin, hard layer gives the material wear-resistant protection.

1.4006 Processing

Machining this material is easy in its annealed and tempered condition. It is not recommended to machine this material if it is hardend above 30 HRC as machining can be challenging.

1.4006 Electrical Discharge Machining (EDM)

Eroding is often used for steels that are difficult to machine and for precise dimensions or shapes that are challenging to achieve with conventional machining methods.

Heat-affected zones may require further heat treatment after eroding to restore the microstructure in the workpiece. After eroding, the recast layer, a thin white layer, should be removed.

1.4006 Dimensional changes

The dimensions can change naturally during heating, when the steel expands, and during cooling, when it contracts, during stress relief or due to uneven heating or cooling, which can cause the material to warp. During heat treatment, 1.4006 undergoes phase changes, transforming from ferrite to austenite when heated and from austenite to martensite when quenched. These changes in the microstructure can also lead to dimensional changes.

Dimensional changes can be prevented or reduced by controlled heating and cooling, by pre-treatment to reduce tension before heat treatment, by careful selection of the quenching medium and, if possible, by manufacturing parts with a machining allowance before heat treatment and subsequent machining to the final dimensions after heat treatment.

1.4006 Forging

To forge this grade of steel, it is slowly and evenly preheated to 800 °C and then quickly brought to a temperature range of 1150 – 1180 °C. Forge the workpiece in the temperature range of 1180 – 950 °C and finish the process with slow cooling in the furnace or in dry ash or another material that promotes slow cooling.

1.4006 Welding

The workpiece should be preheated to 150 – 260 °C and annealed after welding to reduce possible cracking. Since grain formation is to be expected in the heat-affected zone, welding should be carried out with as low a welding energy as possible. Due to the high strength that can be achieved with this steel and the possibility of embrittlement, the use of hydrogen and nitrogen-containing gases during welding should be avoided.