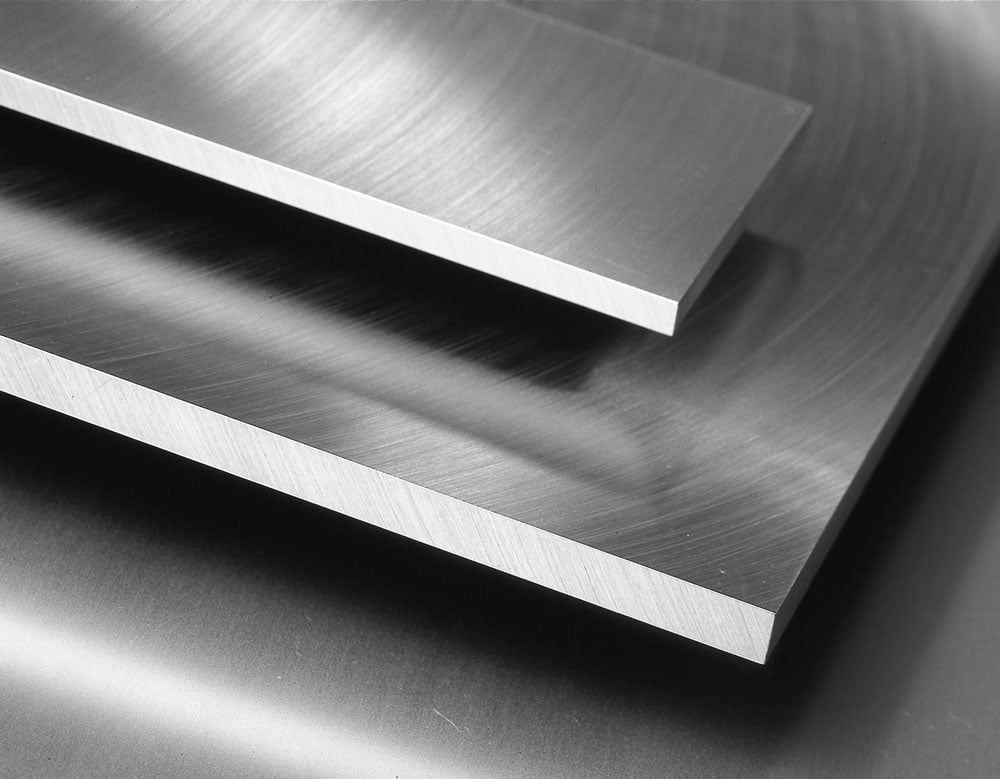

1.7227 QT & 1.7225 QT €co-Präz® flat steel without or with machining allowance - €co-Präz®

WE ARE EXPANDING - GIVING YOU MORE FLEXIBILITY IN YOUR CHOICE

You already know our high-performance materials 1.7225 (42CrMo4) and 1.7227 (42CrMoS4) in annealed form.

As of now, we also offer these materials in a tempered finish.

(QT = Quenched and Tempered).

Physical differences

1.7225 / 1.7227

ANNEALED

Tensile strength:

max. 720 N/mm2

1.7225+QT / 1.7227+QT

TEMPERED

Tensile strength:

ca. 800-900 N/mm2

(round: max. 1300 N/mm2)

Chemical difference

1.7225 / 1.7225+QT

ANNEALED / TEMPERED

“Normal” CrMo heat-treatable steel.

Very low sulfur content. (typ. ≤ 0.035%)

1.7227 / 1.7227+QT

ANNEALED / TEMPERED

Specifically alloyed with sulfur

(typ. ≤ 0.020-0.040% S)

Effect of sulfur

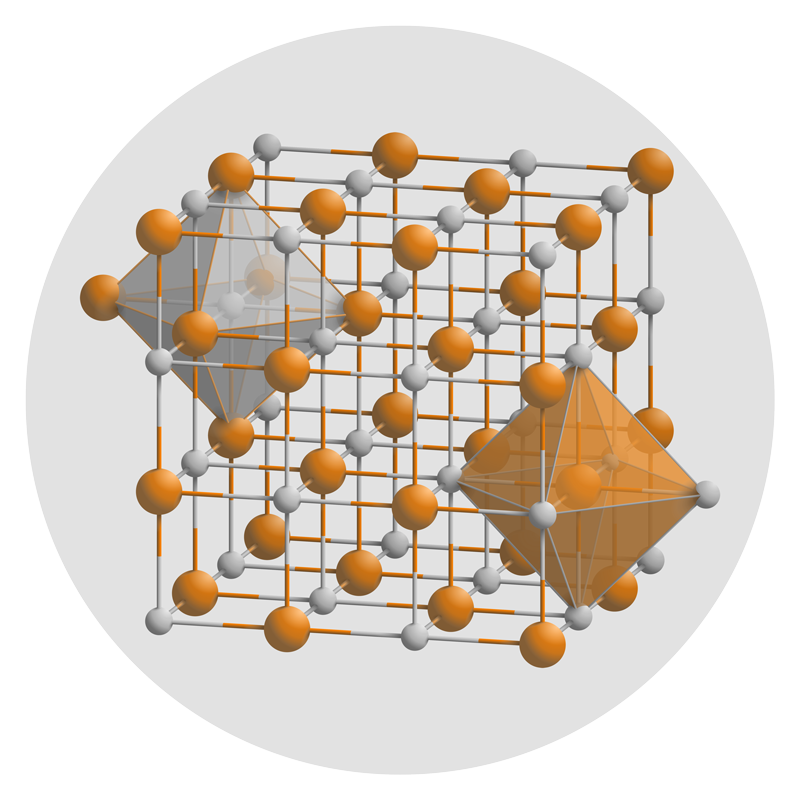

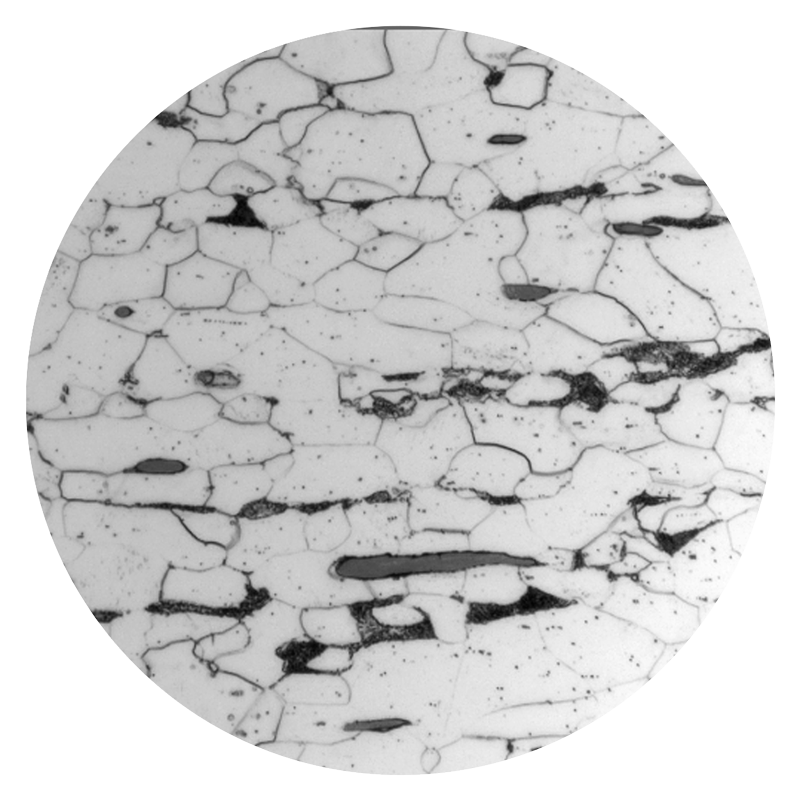

Sulfur combines with manganese to form manganese sulfide inclusions (MnS).

These MnS inclusions act as predetermined breaking points for the chips in the microstructure.

Result:

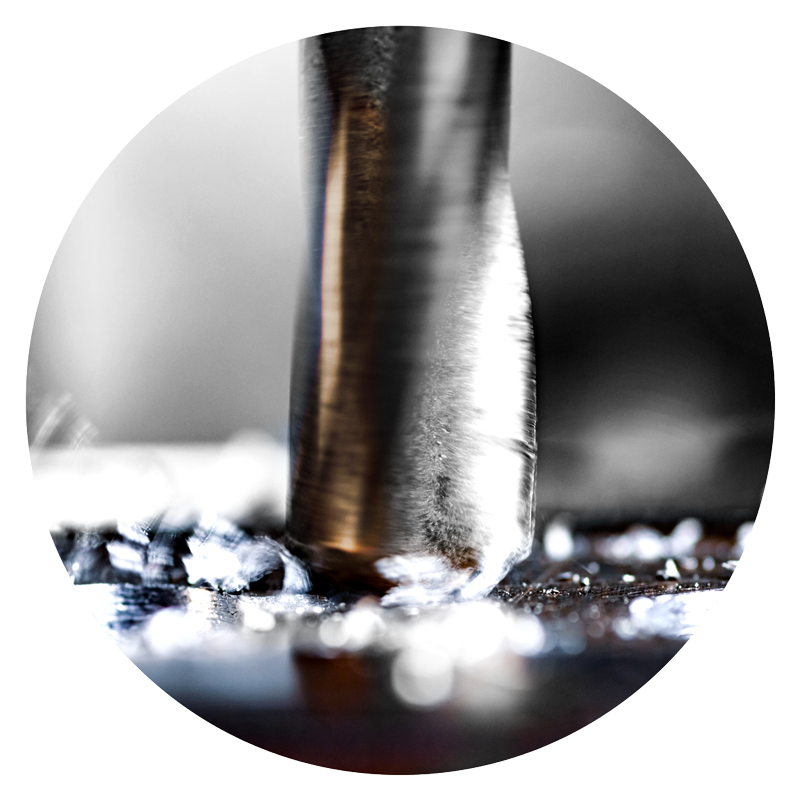

Short, crumbly chips instead of long, tough ribbon chips.

Less chip winding, lower tool load, and easier to automate.

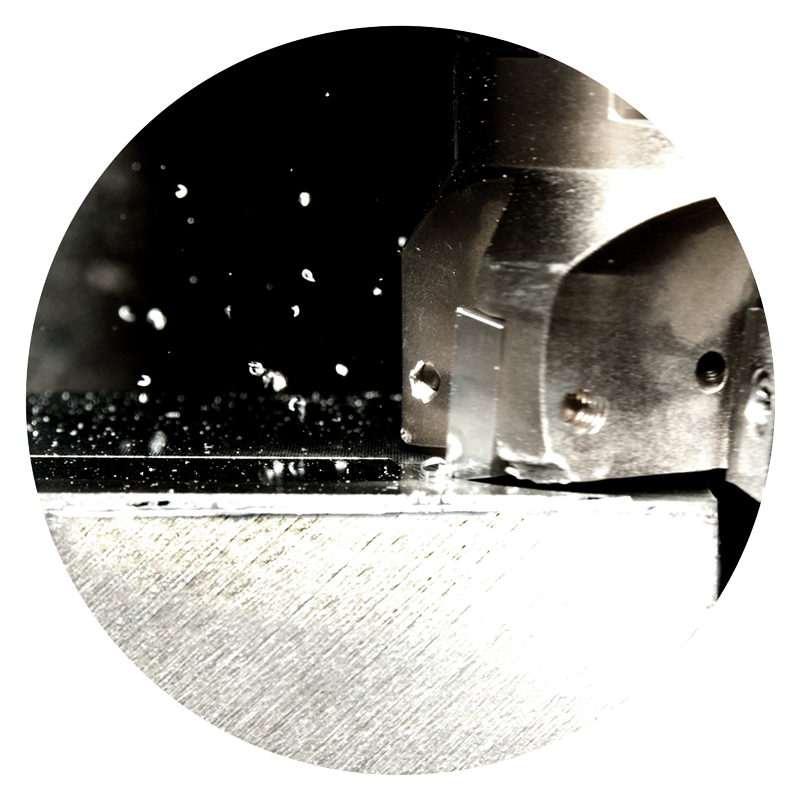

Advantages during machining

Significantly higher strength on delivery

often eliminates the need for further hardening.

High support hardness if the surface layer

is to be nitrided, e.g. due to edge wear.

1.7227 + QT with a defined sulphur

content also enables better machining

Availability from stock enables the fastest

possible completion of your components

Advantages of €co-Präz®

Price advantage

Reduced processing costs compared to conventional precision flat steel

Tight tolerances

High dimensional accuracy in width and thickness

Good flatness

Minimized reworking effort

Clean surfaces

Ready for immediate use in tool and machine construction

1.7225

Discription: 42CrMo4

Condition: annealed

Tensile strength (N/mm2): approx. 720

Hardness (HB): max. 217

Machinability: ⭐️⭐️⭐️⭐️★★

Typical applications:

starting material for shafts, gears, bolts (before tempering)

1.7225+QT

Discription: 42CrMo4+QT

Condition: quenched and tempered (QT)

Tensile strength (N/mm2):

approx. 800-900 (flat) / max. 1300 (round)

Hardness (HB):

max. 270, tempered (flat) / max. 380, tempered (round)

Machinability: ⭐️⭐️⭐️★★★

Typical applications:

Heavily loaded machine components, e.g., guide rails, shafts, spindles, gears, spring-like applications

1.7227

Discription: 42CrMoS4

Condition: annealed

Tensile strength (N/mm2): approx. 720

Hardness (HB): max. 217

Machinability: ⭐️⭐️⭐️⭐️⭐️★

Typical applications:

Starting material for parts

subject to high stress (befor tempering)

1.7227+QT

Discription: 42CrMoS4+QT

Condition: quenched and tempered (QT)

Tensile strength (N/mm2): approx. 800-900 (flat)

Hardness (HB): max. 270, tempered (flat)

Machinability: ⭐️⭐️⭐️⭐️★★

Typical applications:

Highly stressed shafts, spindles, gears, pring-like applications

Order online here - 1.7225+QT flat steel WITHOUT and WITH allowance - length 500 mm

Consulting and

direct contact

Would you like some obligation-free advice or do you need a customized quote?

Our team is ready to help—fast, competent, and solution-oriented.