1.0570 - AT A GLANCE

What kind of steel is the 1.0570?

Der Werkstoff 1.0570 ist ein unlegierter Baustahl, der auch als St52-3 oder als ~S355J2+N bezeichnet wird.

Die Bezeichnung ~S355J2+N steht für:

S

355

J2

+N

= Structural steel

= the minimum yield strength in N/mm2

= is the impact strength at -20°C (min. 27 joules)

= Normalised or normalising rolled for an optimised homogeneity and toughness of this steel grade

S = Struktureller Stahl

355 = die Mindeststreckgrenze in N/mm2

J2 = ist die Kerbschlagarbeit bei -20 °C (mind. 27 Joule)

+N = Normalgeglüht oder Normalisierungsgewalzt zur Verbesserung der Homogenität und Zähigkeit dieser Stahlgüte

The 1.0570 has a good machinability, dimensional stability and due to its low carbon content can be welded well. This naturally hard / annealed tool steel is only used for unhardened components.

Properties

The strutural steel 1.0570 has excellent mechanical properties and weldability. It can be used in many industries due to its good combination of machinability, toughness and strength. All of these properties make the 1.0570 a reliable and cost effective tool steel.

- Unalloyed structural steel

- Good machinability

- Good dimensional stability

- High toughness

- Good weldability due to its low carbon content

- Naturally hard / annealed

- Magnetisable

- Hardening is not usually done

- Polishing is not usually done

- Graining is not commonly done

- Nitirding is not commonly done

Applications

Structural steel 1.0570 is due to its good mechanical properties used in many industries. It has excellent machinability and is due to its low carbon content easiliy weldable. This steel grade is only used for unhardened components.

- Mechanical engineering

- Base plates

- Moulding frames

- Construction materials

- Steel frames

- Hand tools

- Knives

- Sledge hammers

- Spanners

1.0570 Standard values

Chemical composition:

| C | Si | Mn | P | S |

|---|---|---|---|---|

| 0.0 - 0.22 | 0.0 - 0.55 | 0.0 - 1.6 | 0.0 - 0.035 | 0.0 - 0.035 |

Chemical designation:

St52-3 / ~S355J2+N

Working hardness:

approx. 180 HB (annealed)

Delivery condition:

max. 180 HB

1.0570 Physical properties

What group of steel does the 1.0570 belong to?

- Structural steel

- Tool steel

Is the 1.0570 a stainless steel?

To be classified as stainless steel, the material must contain a minimum of 10.5% chromium. 1.0570 contains 0% chromium and is therefore not stainless steel in the traditional sense.

Is the 1.0570 corrosion resistant?

To be corrosion-resistant, a grade must contain a minimum of 10.5% chromium by mass. With 0% chromium, 1.0570 is not corrosion-resistant.

Is the 1.0570 magnetisable?

Yes, as a ferromagnetic steel, the 1.0570 is magnetisable and can be clamped to a magnetic plate for machining.

1.0570 Wear resistance

The structural steel 1.0570 receives on a scale where 1 is low and 6 is high a 1 for its wear resistance.

1.0570 Technical properties

Is the 1.0570 a knife steel?

The 1.0570 / St52 is not a typical knife steel.

A typical knife steel has high hardness, corrosion resistance, wear resistance, can be sharpened and keeps an edge.

1.0570 Working hardness

The 1.0570 achieves a working hardness of approx. 180 HB (natural hardness/annealed).

1.0570 Density

At room temperature the structural steel has a typical density of 7,85 g/cm3.

1.0570 Tensile strength

The tensile strength for the 1.0570 at delivery is at 6250 N/mm2. For this result the material is undergoing a tensile test which shows how much force is needed before the material starts to stretch or elongate before it breaks.

1.0570 Yield strength

Yield strength

Dimentions

Value

<= 100 mm

>= 315 MPa

100 – 250 mm

>= 275 MPa

250 – 500 mm

>= 265 MPa

1.0570 Machinability

On a scale where 1 is low and 6 is high the 1.0570 receives a 6 for its machinabilty.

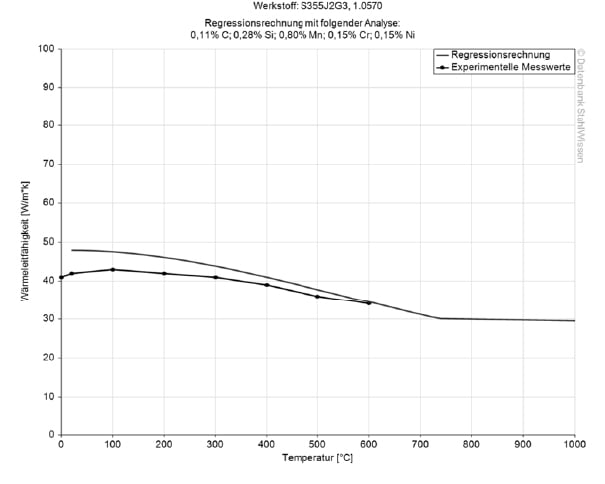

1.0570 Heat conductivity

The heat conductivity for the 1.0570 is between 35,0 – 45,0 W/(m*K) at room temperature.

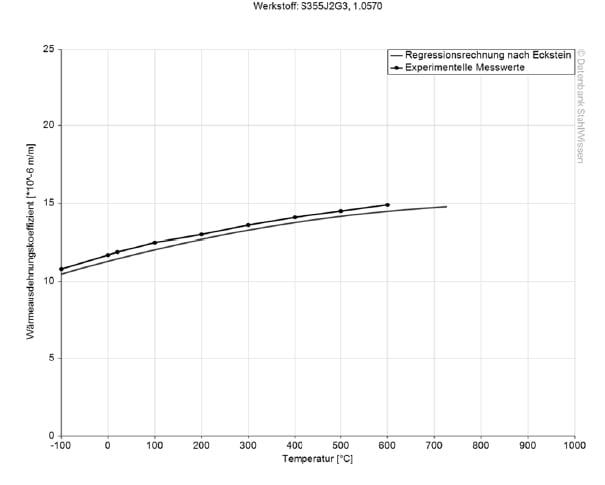

1.0570 Thermal expansion coefficient

The following table shows how much the material expands or contracts at different temperatures. This information can be relevant when when components or parts are exposed to high temperatures or for applications with ever changing temperatures.

Medium thermal expansion coefficient

Value 10-6m/(m*K)

At a temeprature of

11.1

20 – 100 °C

12.1

20 – 200 °C

12.9

20 – 300 °C

13.5

20 – 400 °C

13.9

20 – 500 °C

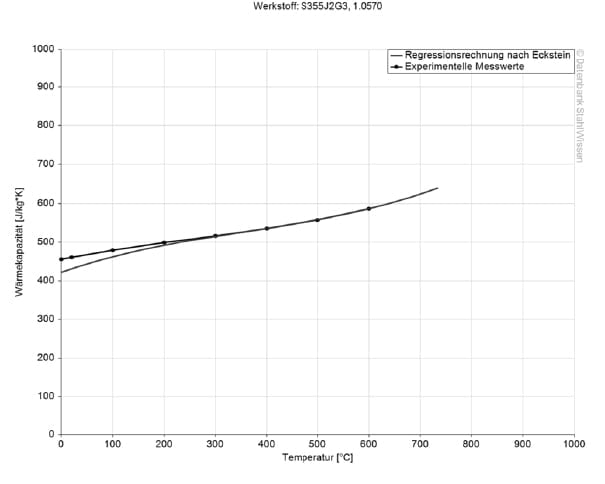

1.0570 Specific heat capacity

The specific heat capacity of the 1.0570 is at 0,46 J/g*K at room temperature.

This value shows how much heat is needed to heat a specific amount of material by 1 Kelvin.

1.0570 Specific electrical resistance

The following table shows the specific electrical resistance. Electrical conductivity is the reciprocal of electrical resistivity.

Specific electrical resistance

Value (Ohm*mm²)/m

Bei einer Temperatur von

0.15

20 °C

PIONEERING!

1.0570 Procedure

1.0570 Heat treatment

The heat treatment determines the material properties and should be carried out with care. Properties such as strength, toughness, surface hardness and temperature resistance are determined, which in turn can extend/improve the service life of parts, tools and components.

Heat treatment includes solution heat treatment, soft annealing, normalising, stress-relief heat treatment, but also tempering, hardening and quenching.

1.0570 Soft annealing

Heat the structural steel 1.0570 evenly to a temperature of and finish the process by cooling the material slowly again in the oven.

1.0570 Stress relieving

To relieve the material of internal stresses after machining or welding evenly heat the material to a temperature of 550 – 580°C and hold for 4 hours. To finish this process let the material cool down in the oven.

1.0570 Normalising

In order to achieve a finer, more homogeneous structure with improved properties, 1.0570 is normalised. To do this, the material is heated to a uniform temperature of 890–950 °C and cooled in air.

1.0570 Surface treatment

In general, polishing is a type of surface treatment that can increase corrosion resistance, for example, but also creates an attractive appearance.

Another type of surface treatment is coating or hardening the surface. To name just a few, the surface can be nitrided, carburised, hard chrome-plated or treated using CVD or PVD processes to give it greater hardness.

In addition to corrosion resistance, various surface treatments can also improve wear resistance, extend service life and reduce friction. The right surface treatment can therefore improve the overall performance of the workpiece and provide even better protection.

1.0570 Processing

1.0570 Forging

For forging, 1.0570 structural steel is heated to a temperature of 850–1050 °C and forged. The forging temperature should not fall below 850 °C.

1.0570 Welding

1.0570 can be welded using all conventional welding methods.

After welding, the material should be stress relieved.