1.2080 mod. - AT A GLANCE

What kind of steel is the 1.2080 mod.?

Steel grade 1.2080 mod. a tool steel that finds its use in cold work. Due to the high content of chromium carbids it has a high wear resistance and edge retention for sheets up to 4 mm thickness. Its full hardenabilty ensures good dimensional stability for work pieces tough with a medium toughness.

Tool steel 1.2080 mod. is a classic amongst the ledeburitic 12% chromium steels.

Properties

Cold work steel 1.2080 mod. has an excellent cutting edge retention for sheets up to 4 mm thickness and dimensional stability even with its high degree of hardness.

- Cold work steel

- 12% chromium steel

- High degree of hardness

- Good dimensional stability

- High wear resistance

- High tempering resistans due to its tungsten content

- Nitriding is not usually done

Applications

Due to its high wear resistance, cutting edge retention and high hardness the corrosion resistant 1.2080 mod. can be used in many different applications and a wide variety of industries.

- Blanking tools

- Stamping tools

- Embossing tools

- Scraping tools

- Trimming tools

- Woodworking tools

- Drawing tools

- Press tools

- Stone moulds

- Sinter tools

- Machine knives

- Hammer cores

- Ring rollers

- Thread rolling dies

- Plastic moulds

1.2080 MOD. Standard values

Chemical composition:

| C | Si | Mn | P | S | Cr | W |

|---|---|---|---|---|---|---|

| 1.9 - 2.2 | 0.1 - 0.6 | 0.2 - 0.6 | 0.0 - 0.03 | 0.0 - 0.03 | 11.0 - 13.0 | ≤ - 0.8 |

Chemical designation:

~X210Cr12

Working hardness:

58-62 HRC

Delivery condition:

max. 255 HB

1.2080 mod. Physical properties

What group of steel does the 1.2080 mod. belong to?

- Ledeburitic tool steel

- Plastic mould steel

- Cold work steel

- Chromium steel

Is the 1.2080 mod. a stainless steel?

As a classic stainless steel, a material must have a mass fraction of at least 10.5% chromium. This means that this tool steel can also be classified in the category of stainless steel, as it contains a mass fraction of 11–13% chromium.

Is the 1.2080 mod. corrosion resistant?

With a mass fraction of 11 – 13 % of chromium the 1.2080 mod. is corrosion resistant.

Is the 1.2080 mod. magnetisable?

Yes, the 1.2080 mod. is ferromagnetic and can be clamped onto a magnetic plate for machining.

1.2080 mod. Cold work

Due to its high carbon and chromium content, 1.2080 mod. exhibits high hardness after heat treatment. A property that gives it its wear resistance during cold forming. To counteract sudden stresses during cold working, this material also has toughness and compressive strength, which are useful for tools that are exposed to such stresses, for example.

1.2080 mod. Wear resistance

This cold-work steel has high wear resistance and scores 5 on a scale where 1 is low and 6 is high.

1.2080 mod. Technical properties

Is the 1.2080 mod. a knife steel?

As a steel with high hardness, cutting durability and wear resistance, 1.2080 mod. can be used as knife steel for cutting tools, machine knives and scissor blades, for example.

Although this material grade has good corrosion resistance, it can be further improved with additional measures such as good and regular maintenance and servicing.

Due to its high hardness, suitable sharpening tools must be used to guarantee long-term cutting performance.

1.2080 mod. Working hardness

The 1.2080 mod. reaches a working hardness of 58 – 62 HRC.

1.2080 mod. Density

At room temperature, the typical density of tool steel 1.2080 mod. is 7.7 g/cm3.

1.2080 mod. Tensile strength

The 1.2080 mod. has a tensile strength of approx. 850 N/mm². To achieve this value, a tensile test is carried out to show how much force is required to stretch or elongate a sample before it breaks.

1.2080 mod. Machinability

On a scale where 1 is low and 6 is high the 1.2080 mod. receives a 1 for its machinability.

1.2080 mod. Heat conductivity

The following table shows the thermal conductivity of tool steel 1.2080 mod. at different temperatures.

Heat conductivity

Value (W/m*K)

At a temperature of

16.7

20 °C

20.5

350 °C

24.2

700 °C

1.2080 mod. Specific heat capacitiy

The specific heat capacity of tool steel 1.2080 mod. at room temperature is 0.46 J/g*K. This value indicates how much heat is required to heat a certain amount of material by 1 Kelvin.

1.2080 mod. Specific electrical resistance

The specific electrical resistance can be found in the following table. Electrical conductivity is the reciprocal of the specific electrical resistance.

Specific electrical resistance

Value (Ohm*mm²)/m

At a temperature of

0.65

20 °C

365 DAYS A YEAR – WE ARE HERE FOR YOU – VISIT OUR ONLINE SHOP AT WWW.PREMIUM-STEEL.CO.UK

1.2080 mod. Surface treatment

In general, polishing is a type of surface treatment that can increase corrosion resistance, for example, but also creates an attractive appearance.

Another type of surface treatment is coating or hardening the surface. To name just a few, the surface can be nitrided, carburised, hard chrome-plated, or treated with CVP or PVD processes to give the surface greater hardness.

In addition to corrosion resistance, the various surface treatments can also achieve wear resistance, longer service life and reduced friction. The appropriate surface treatment can therefore improve the overall performance of the workpiece and protect it even better.

1.2080 mod. Processing

1.2080 mod. Electrical Discharge Machining (EDM)

In general, a material is eroded in order to produce workpieces from a single piece. Erosion can be used to produce dies or more complex shapes. There are various methods of eroding different materials, such as wire erosion, spark erosion or die-sinking erosion.

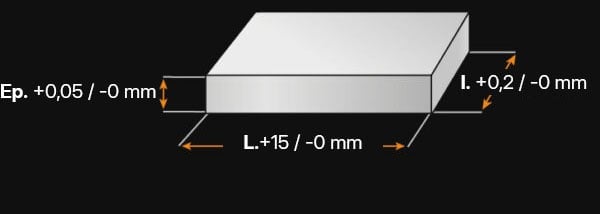

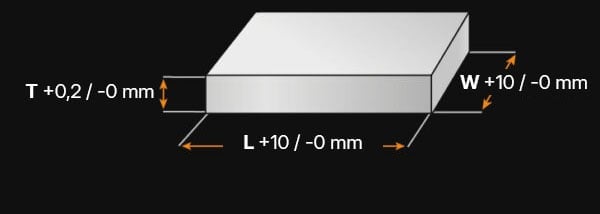

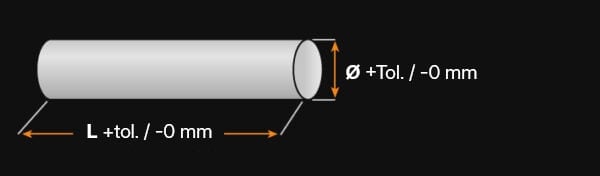

1.2080 mod. Machining allowance / dimensional changes

As with all metals, 1.2080 mod. expands when heated and contracts when cooled. Controlled heating during the hardening and tempering process, as well as during the cooling phase, can minimise deformation and other dimensional changes. In addition, the reduction of stresses and/or dimensional changes should be considered by adding tolerances to the overall dimensions.

1.2080 mod. Forging

The 1.2080 mod. is heated evenly to a temperature of approx. 850 to 1050 °C and then forged. To prevent embrittlement and cracks, workpieces should not fall below 850 °C. If necessary, the workpieces are brought back to the forging temperature.

Finally, the workpieces are slowly cooled again to prevent stress and associated cracks. Slow cooling can take place in the furnace or in a medium that guarantees slow cooling.

To relieve any internal stress, the material can be treated as described in the section ‘Stress relief annealing.

A heat treatment to achieve the desired mechanical properties should complete the forging process.