1.2085 / 1.2099 - AT A GLANCE

What kind of steel is the 1.2085 / 1.2099?

As a martensitic steel the 1.2085 / 1.2099 (X33CrS16 / ~X5CrS12) is magnetizable, has good corrosion resistance even in humid conditions and when processing aggressive plastics. 1.2085 / 1.2099 corrosion resistant tool steel comes in a pre-hardened condition, has good machinability and high strength without the need for a heat treatment.

This steel grade can be used when good machinability with simultaneous corrosion resistance is a priority. 1.2085 / 1.2099 has a good ductility and toughness as well as good dimensional stability.

Properties

1.2085 / 1.2099 is a good choice for plastic moulds and offers an excellent combination of corrosion resistance, wear resistance, dimensional stability and machinability. Its good properties give this steel a long service life, a high surface quality and make it low-maintenance.

Practically, this means:

- Plastic mould steel

- Corrosion resistant

- Resistant to agressive plastics

- For environments with high humidity

- Magnetisable

- Good machinability

- Due to the added sulphur the 1.2085 is better to machine compared to the 1.2316

- With a working hardness of approx. 33 HRC at delivery this pre-hardened grade can be used as delivered

- Further heat treatment is not intended

Applications

Applications for this corrosion resistant tool steel include: Blow molds, packaging, electronic industry, measuring gauges, and optical instruments. Due to the better corrosion resistance, the maintenance requirement for molds is reduced. The 1.2085 / 1.2099 can be used for machine parts or medical devices, which are subjected to wear or require regular cleaning or maintenance, due to its hardness and wear resistance.

- Mechanical engineering

- Apparatus engineering

- Plastic processing

- Injection tools

- Base plates

- Assembling parts

- Mould frames

- Plastic moulds

- Extrusion tools

- Valves

- Steam valves

- Water valves

- Fittings parts

- Pump construction

- Pump rods

- Compressor construction

- Compressor parts

- Surgical instruments

1.2085 / 1.2099 Standard values

Chemical composition:

| C | Si | Mn | P | S | Cr | Ni |

|---|---|---|---|---|---|---|

| 0.28 - 0.38 | 0.0 - 1.0 | 0.0 - 1.4 | 0.0 - 0.03 | 0.05 - 0.1 | 15.0 - 17.0 | 0.0 - 1.0 |

Chemical designation:

X33CrS16 / ~X5CrS12

Working hardness:

approx. 33 HRC (delivery condition) up to 48 HRC

Delivery condition:

max. 330 HB

1.2085 / 1.2099 Physical Properties

What group of steel does the 1.2085 / 1.2099 belong to?

- Martensitic tool steel

- Stainless steel

- Plastic mould steel

Is the 1.2085 / 1.2099 a stainless steel?

To be classified as a stainless steel a steel has to have a mass fraction of a minimum of 10,5 % chromium. With a mass fraction of 12,5 – 17 % of chromium the 1.2088 as well as the 1.2099 can be classified as stainless steels.

Is tool steel 1.2085 / 1.2099 korrosion resistant?

With a mass fraction of 15 – 17 % of chromium in the 1.2085 and 12,5 % in the 1.2099 these grades are corrosion resistant.

1.2085 / 1.2099 General corrosion resistance

In general both steel grades have a good corrosion resistance in acidic environments; regular maintenance and cleaning can positively influence the service life of these steels. Treating or polishing the surface to a high gloss can reduce particles adhereing and stop the advancement of rust. Even if it not normally done, a heat treatment or welding can negatively influence the corrosion resistance.

Is the 1.2085 / 1.2099 magnetisable?

Yes, tool steel 1.2085 / 1.2099 is as a martensitic steel grade magnetisable which makes it possible to use magnetic clamping plates to machine this material.

1.2085 / 1.2099 Hot work

To avoid damages and overheating hot owrk should be done in the recommended temperature range. Stress relieving might need to be done to relive inner stresses which have build up during the process.

1.2085 / 1.2090 Cold work

Due to its tempered condition, cold working of this material can be challenging and generate stresses that can lead to cracks and increased tool wear.

1.2085 / 1.2099 Wear resistance

On a scale where 1 is low and 6 is high the 1.2085 recieves a 3 and the 1.2099 a 2 for its wear resistance.

1.2085 / 1.2099 Technical properties

Is the 1.2085 / 1.2099 a knife steel?

Normally the 1.2085 / 1.2099 is not used for knife making. A good knife steel has a good balance of corrosion resistance, edge retention, chipping resistance and easy sharpening. Even if these steel grades show some of the foremeationed properties others like the edge retention are to low to be used to make quality knives. Most knives need approx. 56 – 60 HRC to keep an edge and have the appropriate toughness.

1.2085 / 1.2099 Working hardness

The working hardness for the 1.2085 is at approx. 33 (on delivery) – 48 HRC and for the 1.2099 approx. 33 HRC (on delivery).

1.2085 / 1.2099 Density

At room temperature the density for steel grade 1.2085 is normally at 7,85 g/cm3 for the 1.2099 normally at 7,71 g/cm3.

1.2085 / 1.2099 Machinability

With the addition of sulphur this steel grade has a good machinabilty. As a pre-hardened steel grade the 1.2085 / 1.2099 can be machined by milling, drilling and turning. To avoid tool wear cutting tools should be well maintained and sharp. To avoid friction and wear of tools as well as heat development between the tool and the work piece a cutting fluid should be used.

After machining the steel the work pieces should be stress relieved, this is less of a problem with pre hardened steel but can effect the dimensional stability of precision work pieces.

On a scale where 1 is low and 6 is high the 1.2085 receives a 5 and the 1.2099 a 6 for its machinability.

1.2085 / 1.2099 Tensile strength

On delivery the 1.2085 / 1.2099 has a tensile strength of approx. 1125 N/mm2. To receive this value a tensile test is performed to show how much strength is needed in order to stretch or elongate a sample before it breaks.

1.2085 / 1.2099 Heat conductivity

At a temperature of 20 °C the heat conductivity fot the 1.2085 is at 23,4 W/(m*K) and for the 1.2099 at 23,9 W/(m*K).

1.2085 / 1.2099 Thermal expansion coefficient

The thermal expansion coefficient shows how much a material expands or contracts at any temperature changes. This information can be relevant when when components or parts are exposed to high temperatures or for applications with ever changing temperatures.

Medium thermal expansion coefficient

Value 10-6m/(m*K)

At a temperature of

10.25

20 – 100 °C

10.72

20 – 200 °C

11.14

20 – 300 °C

11.58

20 – 400 °C

12.02

20 – 500 °C

1.2085 / 1.2099 Specific heat capacity

The specific heat capacity of tool steel 1.2083 ESR at room temperature is 0,46 J/kg*K. This value shows how much heat is needed to heat a specific amount of material by 1 Kelvin.

HEART AND SOUL IN STEEL!

1.2085 / 1.2099 Procedure

1.2085 / 1.2099 Heat treatment

Since material 1.2085 / 1.2099 is generally supplied in a pre hardened condition, no further heat treatment is necessary. The following processes can be used if a higher hardness is required.

1.2085 / 1.2099 Annealing

Heat the material 1.2085 / 1.2099 evenly to 850 – 880 °C and hold it there for 2 to 5 hours, then cool the material slowly in the furnace to a temperature of 500 °C, after which the material can be further cooled in air, in ash or an insulating material.

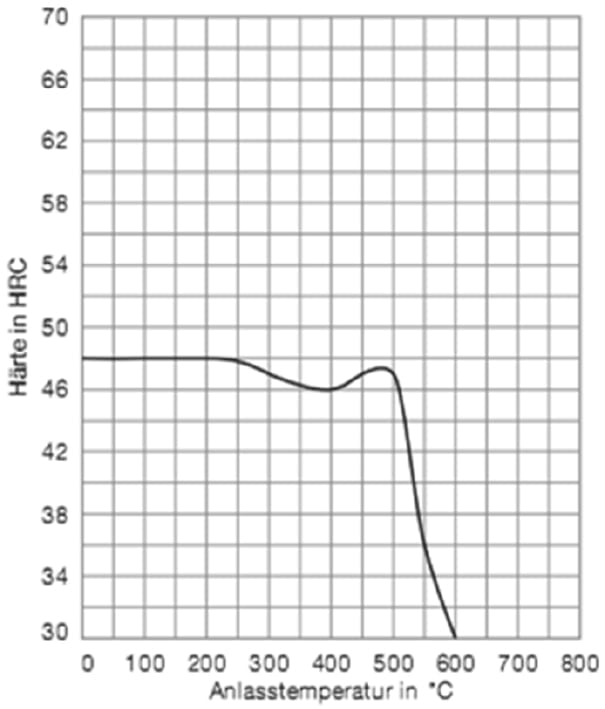

1.2085 / 1.2099 Tempering

To reduce the brittleness of the phase change after quenching while maintaining the hardness achieved, slowly heat the 1.2085 / 1.2099 to a tempering temperature of 200 – 300 °C and hold it for 2 hours per 20 mm thickness. Double tempering is recommended. This process is completed with slow cooling in the furnace.

1.2085 / 1.2099 Heat treatment

Since material 1.2085 / 1.2099 is generally supplied in a pre hardened condition, no further heat treatment is necessary. The following processes can be used if a higher hardness is required.

1.2085 / 1.2099 Hardening

Heat the tool steel evenly to 1000–1030 °C and maintain this temperature for 30 minutes. To prevent decarburization and oxidation, the material should be protected during the hardening process. The workpieces are then quenched in oil.

1.2085 / 1.2099 Quenching

Quenching this material converts austenite into martensite, a hard and brittle phase.

- Oil

- Compressed gas (N2)

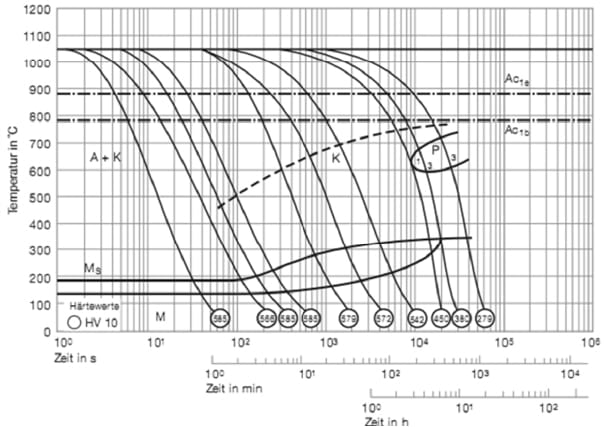

1.2085 / 1.2099 Continuous TTT-Diagram

The TTT-diagram usually shows micro-changes over time at different temperature . These are important in heat treatment as they provide information on the optimal conditions for processes such as hardening, annealing and normalising.

1.2085 / 1.2099 Surface treatment

Each surface treatment has its own advantages and should be selected based on the required properties, the desired finish, and/or the environment in which the workpiece will be used. Here are some examples of surface treatments:

1.2085 / 1.2090 Black oxide coating or blueing

Bluing of material 1.2085 / 1.2099 gives tools and workpieces a black mixed oxide layer that provides them with a certain degree of corrosion protection.

However, bluing is usually carried out for aesthetic reasons. It gives the parts a blue-black color that reduces light reflection on the surface.

1.2085 / 1.2099 PVD- and CVD coating

In both processes, a thin protective layer is applied to the surface of the material, which increases hardness, reduces friction, and improves wear resistance.

- PVD – physical vapor deposition

- CVD – chemical vapor deposition

1.2085 / 1.2099 Passivation

Passivation refers to the removal of free iron from the surface by treating the surface with an acid solution, such as citric or nitric acid. Passivation creates a protective oxide layer which increases the corrosion resistance of this material.

1.2085 / 1.2099 Coating

A coating such as hard chrome plating or chemical nickel plating can increase wear resistance and corrosion resistance and can also be used for decorative purposes.

1.2085 / 1.2099 Processing

1.2085 / 1.2099 Electrical Discharge Machining (EDM)

As a pre heated material, the 1.2085 / 1.2099 can be machined by EDM. EDM allows complex and precise shapes to be produced, which may be more difficult with conventional machining. After EDM, polishing or a heat treatment may be required to remove any residual stresses or restore surface properties.

1.2085 / 1.2099 Dimensional changes

Intense heat treatment can cause deformation or dimensional changes.

1.2085 / 1.2099 Sub-zero treatment

After quenching, some austenite may remain. This residual austenite can be converted to martensite by a low-temperature treatment. After treating the steel at these low temperatures, the material must be tempered to restore its good balance of properties.

Cryogenic treatment can have a positive effect on the wear resistance, dimensional stability, hardness, and toughness of 1.2085 / 1.2099.

1.2085 / 1.2099 Welding

Heat the work pieces uniformly to a temperature of 1050 – 850 °C. Cool the work pieces slowly after the welding process.