1.2162 - AT A GLANCE

1.2162 - AT A GLANCE

The 1.2162 is a cold work and plastic mould steel with high strength, good toughness, hardenability and machinability. After case hardening this tool steel grade it has a tough core and a hard shell which makes it useful for a wide variety of applications like nuts and bolts, spindles and camshafts and pinions and shafts.

Properties

The 1.2210 has a good combination of strength, hardness and toughness. Due to those properties it is a great choice for applications with high stress and for applications that need good wear resistance. To give this tool steel even better wear resistance and/or enhance its corrosion resistance it can be surface treated to enhance tool service life. This steel grade can be hardened trough or case hardened which can both be useful for several different applications.

- Cold work steel

- Plastic mold steel

- Wear-resistant surface

- Tough core

- Very good machinability

- Good cold sinkability

- Good polishability

- Component tensile strength results from the combination of a hardened surface layer and a tough core

Applications

The 1.2162 is a case hardening steel, which is often used for medium to highly stressed parts, for example gears, gear shafts and connecting rods, in the automotive and general engineering industry.

It also finds its uses as mold plates due to its surface hardness or resin press molds to process thermoplastics as well as gauges, other measuring tools and auxiliary tools such as clamping tools. This case hardening mold steel can reach a core strength of approx. 1.000 – 1.300 N/mm2.

- Mechanical engineering

- Jig construction

- Plant engineering

- Apparatus engineering

- Plastic processing

- Plastic molds

- Synthetic resin mold tools

- Base plates

- Bending bars

- Guide columns

- Gear parts

- Joint parts

- Shafts

- Gears

- Rods

- Bevel gears

- Crown wheels

- Piston pins

- Camshafts

- Bolts

- Pins

- Cardan joints

1.2162 Standard values

Chemical composition:

| C | Si | Mn | P | S | Cr |

|---|---|---|---|---|---|

| 0.18 - 0.24 | 0.15 - 0.35 | 1.1 - 1.4 | 0.0 - 0.03 | 0.0 - 0.03 | 1.0 - 1.3 |

Chemical designation:

21MnCr5

Working hardness:

58-60 HRC

Delivery condition:

max. 217 HB

1.2162 Physical Properties

What group of steel does the 1.2162 belong to?

- Tool steel

- plastic mould steel

- Cold work steel

- Case hardening steel

Is the 1.2162 a stainless steel?

Stainless steel must have a minimum chromium content of 10.5%. With a chromium mass fraction of 1–1.3%, the 1.2162 is not stainless steel.

Is the 1.2162 corroison resistant?

The steel grade must have a chromium content of at least 10.5% to be classified as corrosion resistant. 1.2162 has a maximum content of 1.3% and is therefore not a traditional corrosion resistant steel.

Is the 1.2162 magnetisable?

As a ferro magnetic steel the 1.2162 can be magnetised which makes it possible to use magnetic clamping plates to machine this material.

1.2162 Waer resistance

On a scale where 1 is low and 6 is high the 1.2162 receives a 5 for its wear resistance.

1.2162 Technical properties

Is the 1.2162 a knife steel?

After proper heat treatment, the 1.2162 has a balanced ratio of hardness and toughness, allowing it to retain its sharpness and prevent splintering. Since 1.2162 is not corrosion

resistant, it must be thoroughly maintained, e.g., cleaned regularly, kept dry, and oiled if necessary to prevent the blade from rusting. With this in mind, 1.2162 can be used for outdoor knives, cutlery knives, or utility knives.

1.2162 Working hardness

The working hardness of tool steel 1.2162 is at 58 – 60 HRC.

1.2162 Density

The typical density for tool steel 1.2162 at room temperature is 7,85 g/cm3.

1.2162 Tensile strength

At delivery the tool steel 1.2162 has a tensile strength of approx. 720 N/mm2. To receive this value a tensile test is performed to show how much strength is needed in order to stretch or elongate a sample before it breaks.

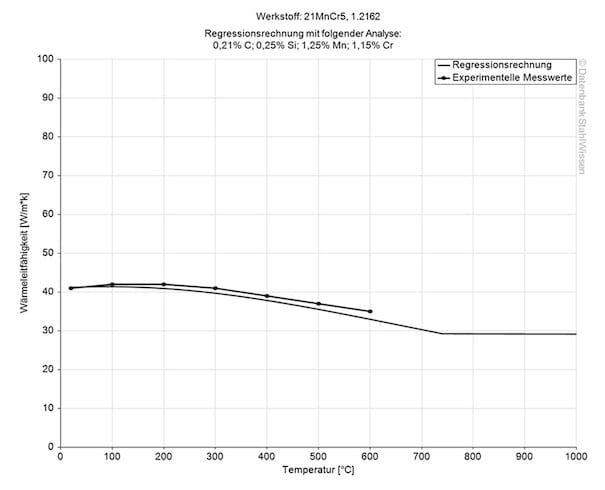

1.2162 Heat conductivity

The heat conductivity for steel grade 1.2162 at a temperature of 20 °C is at 39,5 W/(m*K).

Heat conductivity

Value W/(m*K)

At a temperature of

39.5

20 °C

36.5

350 °C

33.5

700 °C

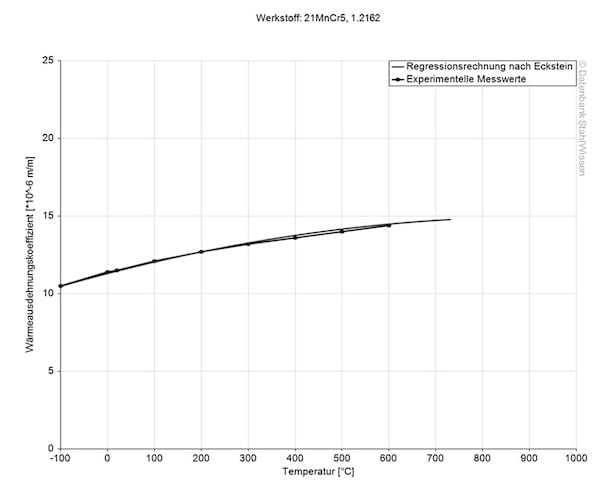

1.2162 Thermal expansion coefficient

The following table shows by how much this steel expands or contracts at different tempeartures which can be very important when working with high temperatures or rapidly changing temperatures.

Medium thermal expansion coefficient

Value 10-6m/(m*K)

At a temperature of

12.2

20 – 100 °C

12.9

20 – 200 °C

13.5

20 – 300 °C

13.9

20 – 400 °C

14.2

20 – 500 °C

14.5

20 – 600 °C

14.8

20 – 700 °C

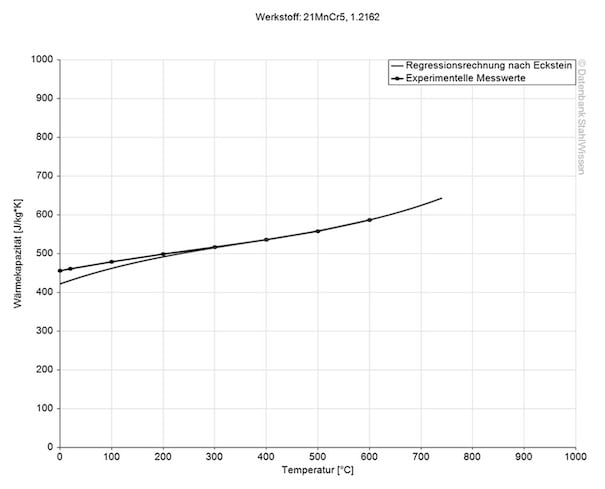

1.2162 Specific heat capacity

The specific heat capacity of tool steel 1.2162 at room temperature is 0,475 J/kg*K. This value shows how much heat is needed to heat a specific amount of material by 1 Kelvin.

1.2162 Specific electrical resistance

The following table shows the specific electrical resistance for the 1.2162.

Specific electrical resistance

Value (Ohm*mm2)/m

At a temperaure of

0.16

20 °C

PERFECTION!

1.2162 Procedure

1.2162 Annealing

Heat the workpieces evenly to a temperature of 670 – 710 °C and finish the process by slowly cooling them in the furnace. This process can reduce the hardness of the steel or increase its toughness, as well as relieve internal stresses.

1.2162 Intermediate annealing

Heat the case-hardening steel 1.2162 to a temperature of 630 – 650°C for approx. 2 – 4 hours and then allow it to cool slowly in the furnace.

1.2162 Normalising

To normalise the tool steel 1.2162 heat it uniformly to a temperature of 900 – 930 °C and after cool it slowly to ambient temperture in air. This process will give the material a finer corn structure as well as a better toughness, strength and machinability.

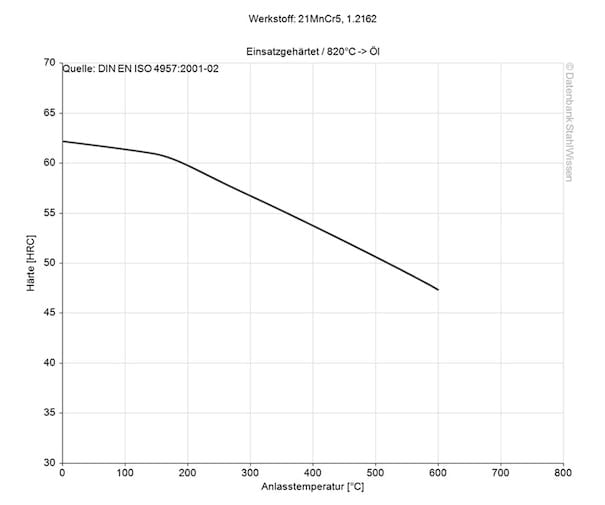

1.2162 Tempering

With a minimum of 2 hours or 1 hour per 20 mm thickness heat the material to a temperature of 170 – 210 °C. By tempering residual stresses can be alleviate which have build up during the quenching process of the 1.2162.

1.2162 Hardening (core hardening)

Heat the material to a hardening temperature of 850 – 880 °C and quench it in oil or water (water is only used for large, simply shaped components) to a temperature of 160 – 250 °C.

1.2162 Hardening (case hardening)

Heat the material to a hardening temperature of 810 – 840 °C and quench it in oil or water (water is only used for large, simply shaped components) to a temperature of 160 – 250 °C.

1.2162 Quenching

Rapid quenching of the 1.2162 after carburizing traps the added carbon in the surface.

- Oil

- Water ( for simple shaped components)

- Salt bath

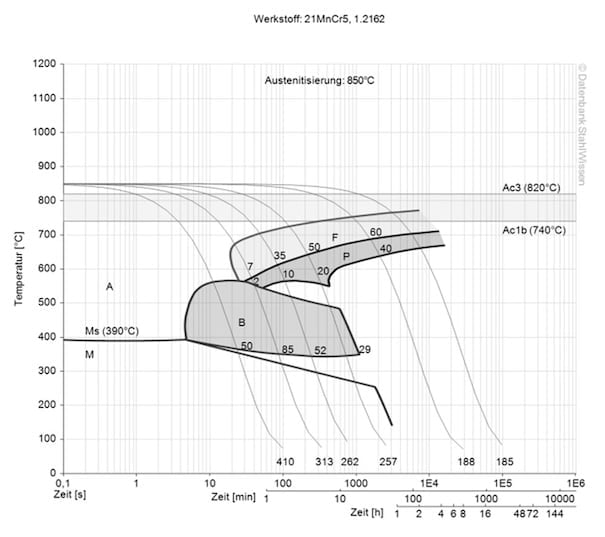

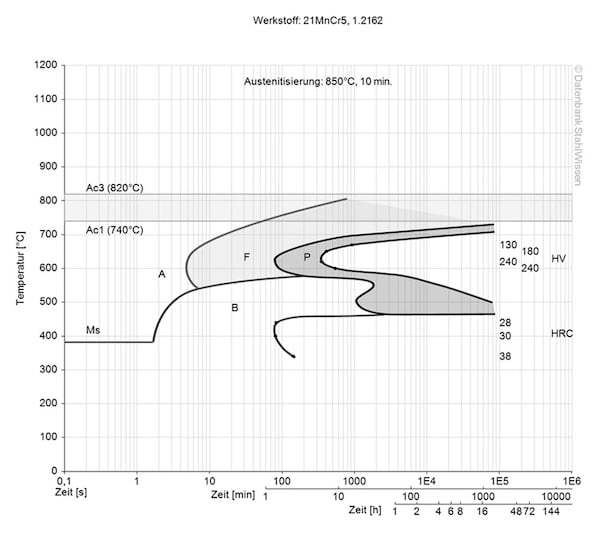

1.2162 Continuous TTT-diagram

The TTT-diagram usually shows micro-changes over time at different temperature. These are important in heat treatment as they provide information on the optimal conditions for processes such as hardening, annealing and normalising.

1.2162 Isothermal TTT-diagram

This diagram shows the structural changes at micro level over time at a constant temperatur. It shows at which temperatures after what time the different phases like perlit, martensite or bainite start to form.

1.2162 Surface treatment

A surface treatment can improve wear resistance, corrosion resistance and surface hardness and to increase the service life of tools and components. Following are a selection of surface treatments for the 1.2162.

1.2162 Nitriding

The surface of the 1.2162 is not usually treated when hardened as this results in a loss of hardness.

1.2162 Carbonitriding / Case hardening

When case hardening carbon is diffused into the surface of the 1.2162 the so called carburisation to improve the wear resistance of the steel. The carbon should be envenly distributed to avoid weak spots in components and tools.

1.2162 Carburising

Heat the material to a temperature range of 900 – 950 °C. Keep the intended use and the desired microstructure when choosing the temperature, time, medium and equipment. During carburising, carbon is introduced into the surface of the material to give it a harder shell and a tough core. This makes the material wear resistant and tough enough to withstand high loads.

1.2162 Hard chrom plating

This process overlays the material with a thin layer of chromium. This gives the material improved hardness, wear resistance and corrosion resistance.

1.2162 Processing

1.2162 Electrical Discharge Machining (EDM)

Erosion is used for workpieces that are manufactured from a single piece, for cutting dies or for producing complex or delicate shapes. There are various methods of eroding different materials, some of which include wire erosion, spark erosion and sinker erosion.

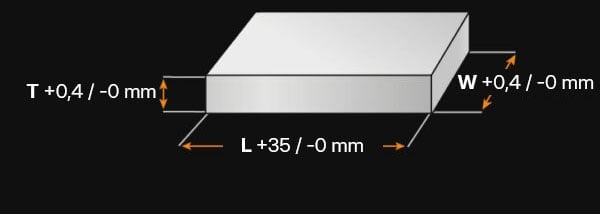

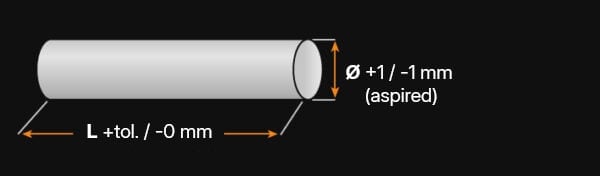

1.2162 Machining allowance / dimensional changes

Like all steel, 1.2162 expands during the heating process and contracts during the cooling process.

Since the carburisation of steel involves high temperatures, care must be taken to ensure that the material does not deform during this process.

1.2162 Forging

Forging should be carried out at a temperature range of 1050–850 °C, after which the material should be slowly cooled in the furnace.

1.2162 Welding

Material 1.2162 has limited weldability. Welding should be carried out before heat treatment. Preheat the workpiece to 250–350 °C; the subsequent heat treatment depends on the heat treatment of the base material.