1.2311 - AT A GLANCE

What kind of steel is the 1.2311?

The 1.2311 (40CrMnMo7) is delivered as pre-hardened material and can be used in its delivered condition which is beneficial when making moulds. In general, 1.2311 tool steel is mainly used for plastic moulds, die casts and tools but is also suitable for applications such as rails and shafts. The steel grade has good weldability and can be polished to an excellent finish.

It has a high through-hardenability and uniform component strength which is an advantage when maintaining consistent performance of tools and moulds. For a higher hardness the 1.2311 can be further hardened but its hardenability is compared to other tool steels limited. In addition this steel grade is not suited for applications with high stresses.

Properties

As a tool steel the 1.2311 is a dependable and accomplished choice when it comes to moulds, dies and tools. It has a great balance of machinability and toughness and is easy to polish which again is beneficial to the finish of the moulded products.

- Quenched and tempered cold work steel

- Plastic mould steel

- Polishable, better than 1.2312

- Etchable

- High through-hardening

- Uniform component strength

- Nitridable

- EDM machinable

Applications

No further heat treatment for the 1.2311 is intended, this makes it usable as delivered and without any delays.

As further heat treatment is not needed the risks of distortion during the heat treatment are eliminated and needed properties like high wear resistance, toughness for moulds, dies, jigs and tooling is evenly spread throughout.

- Mechanical engineering

- Jigs

- Base plates

- Assembling parts

- Moulding frames

- Plastic molds

- Plastic processing

- Injection moulds

- Die casting moulds

- Hydroforming tools

- Recipient sleeves

- Intermediate sleeves

- Folding bars

- Tool holders

- Extrusion presses

- Tube presses

- Die holders

- Die insert

1.2311Standard values

Chemical composition:

| C | Si | Mn | P | S | Cr | Mo |

|---|---|---|---|---|---|---|

| 0.35 - 0.45 | 0.2 - 0.4 | 1.3 - 1.6 | 0.0 - 0.035 | 0.0 - 0.035 | 1.8 - 2.1 | 0.15 - 0.25 |

Chemical designation:

40CrMnMo7

Working hardness:

approx. 32 HRC (delivery condition) up to 50 HRC

Delivery condition:

max. 325 HB

1.2311 Physical properties

What group of steel does the 1.2311 belong to?

- Cool steel

- Cold work steel

- Plastic mould steel

Is the 1.2311 a stainless steel?

In the classical sense the 1.2311 is not a stainless steel. To be classified as a stainless steel the material has to have a mass fraction of at least 10,5 % of chromium. This material grade has a mass fraction of 1,8 – 2,1 % of chromium.

Is the 1.2311 corrosion resistant?

With a mass fraction of 1,8 – 2,1 % of chromium the 1.2311 is not a corrosion resistant steel.

An additional surface treatment or maintenace as well as appropriate storage of parts in dry environments can extend the corrosion resistance but cannot completely prevent rusting.

Is the 1.2311 magnetisable?

Yes, as the 1.2311 contains iron it canbe magnetised. Grinding, milling and eroding can be carried out on machines with magnetic adhesion, for example.

1.2311 Cold work

The 1.2311 can be cold worked with all the usual processing methods.

1.2311 Wear resistance

On a scale where 1 is low and 6 is high the 1.2311 receives a 3 for its wear resistance.

1.2311 Technical Properties

Is the 1.2311 a knife steel?

The 1.2311 is not usually used to produce knives. He has a good edge retention, toughness, corrosion resistance or hardness but not evough to make knives with.

1.2311 Working hardness

The working hardness for the 1.2311 is at 32 – 50 HRC.

1.2311 Density

1.2311 Tensile strength

The 1.2311 has a tensile strength of approx. 1100 N/mm2. To receive this value a sample will be used for a tensile test to see how much stresses can be loaded until it elongates and then breaks.

1.2311 Yield strength

The yield strength shows how much stress is needed before the material starts to plastically deforms and when the point is reached when the material does not return into its original form after the stress is removed.Then it either stays deformed or even breaks.

The yield strength for tool steel is in a range of 827 – 862 N/mm2.

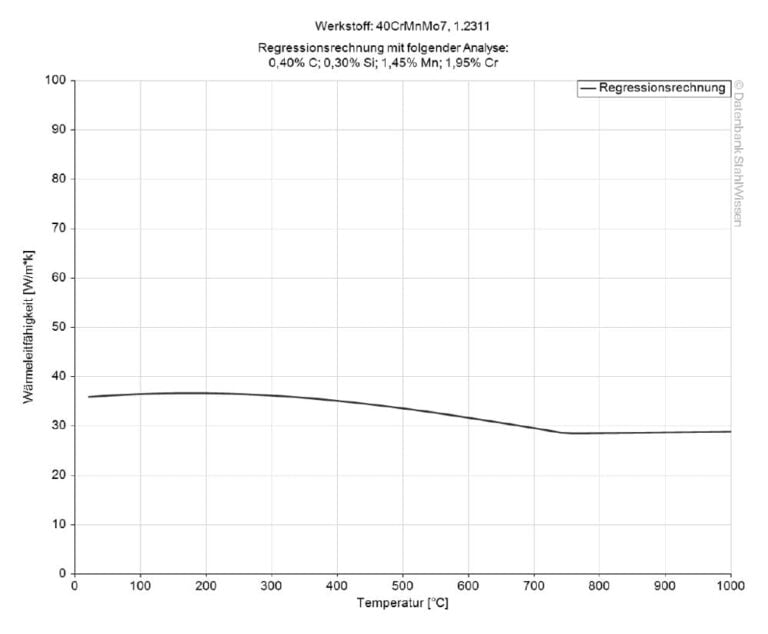

1.2311 Heat conductivity

At a temperature of 23 °C the 1.2311 has a heat conductivity of 32,5 W/(m*K).

Heat conductivity

Value W/(m*K)

At a temperature of

32.5

23 °C

32.9

150 °C

31.3

300 °C

30.2

350 °C

29.5

400 °C

27.4

500 °C

1.2311 Machinability

The 1.2311 receives a 3 for its machinability on a scale where 1 is low and 6 is high.

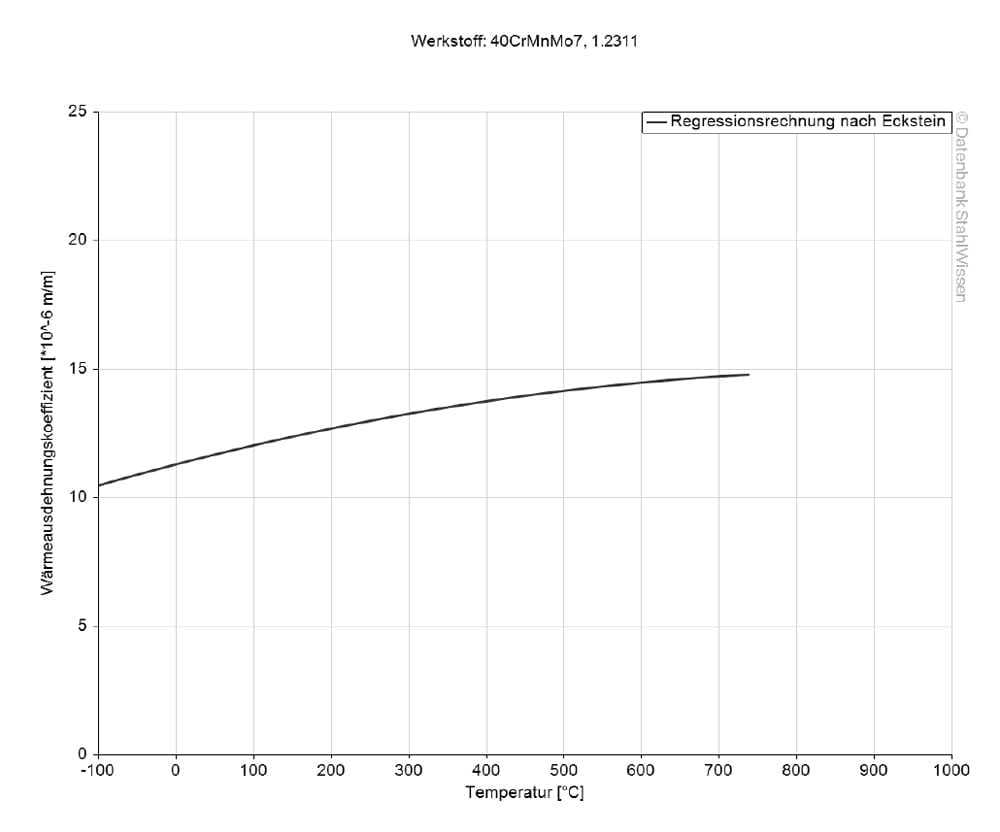

1.2311 Termal expansion coefficient

The following table shows the expansion or contraction at different temperatures. This can be very improtant when working with high or ever changing temperatures.

Medium thermal expansion coefficient

Value 10-6m/(m*K)

At a temperature of

12.6

20 – 100 °C

13.0

20 – 200 °C

13.5

20 – 300 °C

13.7

20 – 350 °C

13.9

20 – 400 °C

14.1

20 – 450 °C

14.3

20 – 500 °C

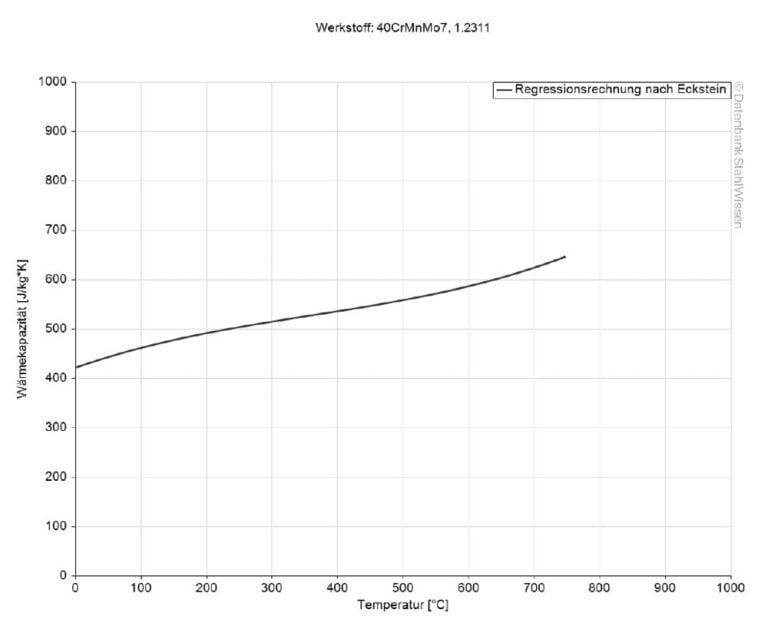

1.2311 Specific heat capacity

At room temperature the specific heat capacity of the 1.2311 is at 0,46 J/kg*K. This value shows how much heat is needed to heat a specific amount of material by 1 Kelvin.

1.2311 Specific electrical resistance

The following table shows the specific electrical resistance. Electrical conductivity is the reciprocal of electrical resistivity.

Specific electrical resistance

Value (Ohm*mm2)/m

At a temperature of

0.47

20 °C

PERFECT MATERIAL SELECTION WITH THE ABRAMS STEEL GUIDE®: WWW.STEEL-GUIDE.CO.UK

1.2311 Procedure

1.2311 Heat treatment

Heat treatment is not normally required for 1.2311 as it is supplied pre-hardened. For re-hardening, if necessary, follow the steps below.

1.2311 Annealing

Heat the material evenly to a temperature of 710–740 °C and then cool it in the furnace.

1.2311 Stress relieving

1.2311 should be stress relieved after machining and occasionally during use. Heat the workpiece evenly to 550–600 °C and hold it for 1 hour per 25 mm thickness, then cool the material in the furnace.

Stress relief prevents 1.2311 from deforming or cracking, improves the mechanical properties of the material and increases the dimensional stability which is important for moulds.

1.2311 Normalising

Normalising refines the grain structure and gives the steel a uniform structure. It can help to improve machinability and reduce internal stresses caused, for example, by previous heat treatment, forging or casting.

Heat the material evenly above its critical temperature and hold it there for approx. 1 hour per 25 mm of thickness. Then remove the parts from the furnace and cool them in still air.

Finish the process with a thorough inspection to ensure that the parts have the desired structure and properties.

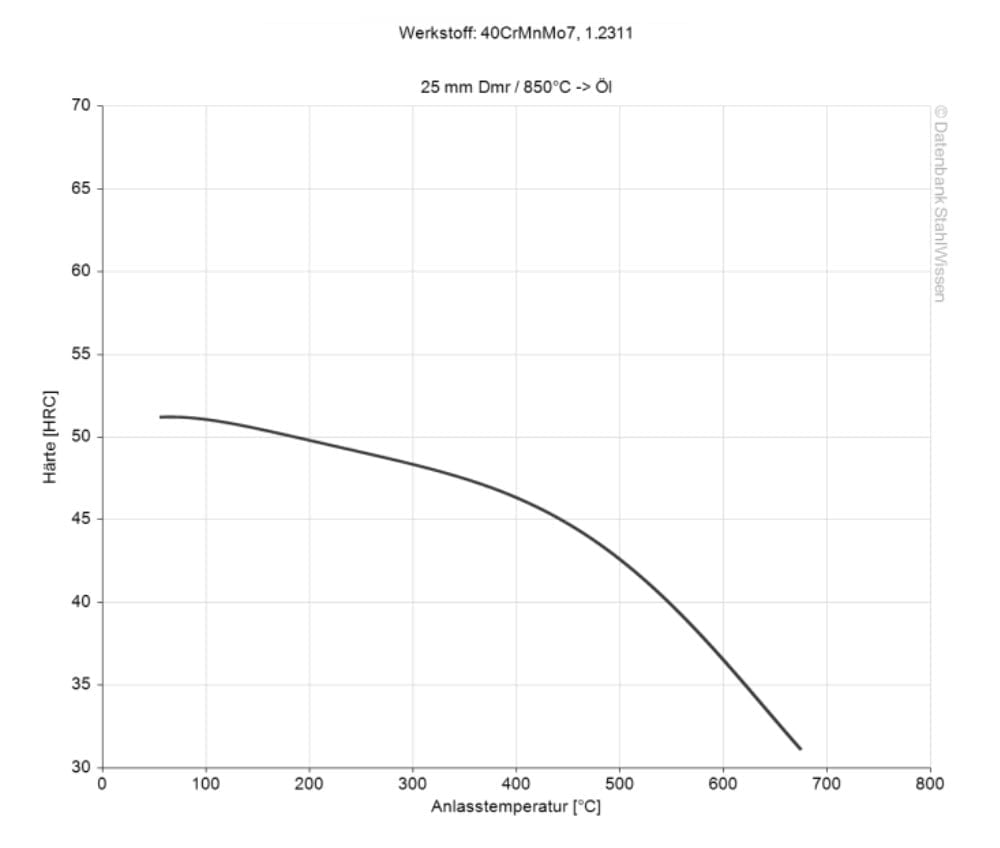

1.2311 Tempering

The workpieces should be tempered immediately after quenching. The tempering temperature should be maintained for at least 2 hours or 1 hour per 25 mm thickness, then the workpieces should be allowed to cool to room temperature in air.

1.2311 Hardening

To re-harden material 1.2311 (if necessary), heat it evenly to a temperature of 840 – 870 °C, hold it for 30 minutes for the first 25 mm and for 15 minutes for each additional 25 mm of thickness.

1.2311 Quenching

The material should be quenched at a temperature of 180 – 200 °C in the following media:

- Oil

- Salt bath

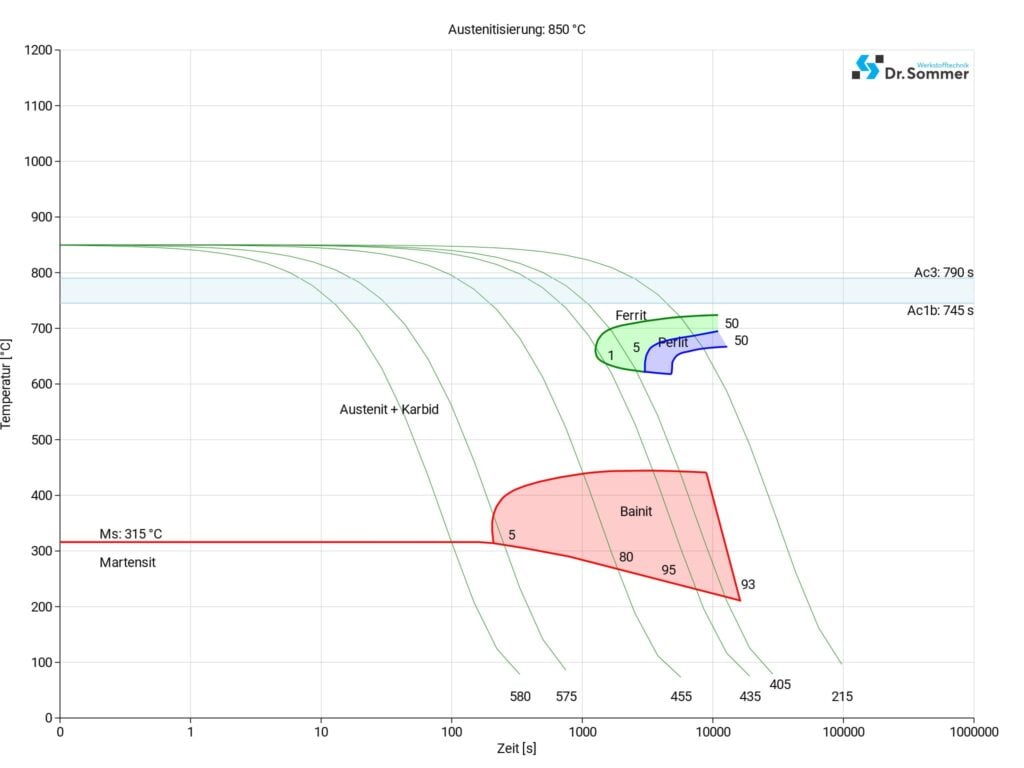

1.2311 Continuous TTT-Diagram

The TTT-diagram usually shows micro-changes over time at different temperature. These are important in heat treatment as they provide information on the optimal conditions for processes such as hardening, annealing and normalising.

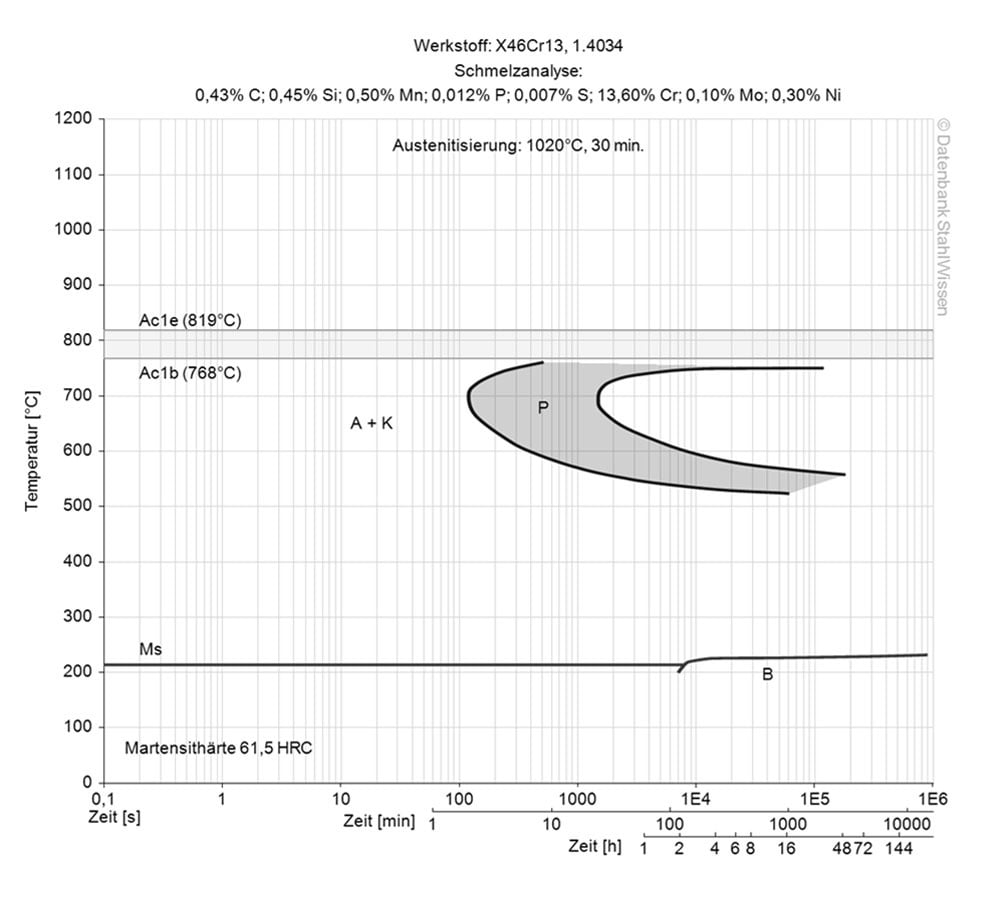

1.2311 Isothermal TTT-diagram

This diagram shows the structural changes at micro level over time at a constant temperatur. It shows at which temperatures after what time the different phases like perlit, martensite or bainite start to form.

1.2311 Surface treatment

Following are a few examples for a possible surface treatment for the 1.2311.

1.2311 Nitriding

Tool steel 1.2311 can be nitrided to obtain a hard and abrasion-resistant surface to a depth of 0,40 mm. During nitriding, nitrogen is diffused into the surface to achieve this.

1.2311 Black oxide coating or blueing

Bluing of material 1.2311 gives tools and workpieces a black mixed oxide layer, which provides them with a certain degree of corrosion protection.

However, bluing is usually carried out for aesthetic reasons. It gives the parts a blue-black colour, which reduces light reflection on the surface.

1.2311 PVD coating

Physical vapour deposition (PVD) is used to apply a thin film to the surface of the material, which increases wear resistance and can reduce friction.

1.2311 Polishing

1.2311 can be polished to a high gloss using suitable methods. To avoid an orange peel effect and pitting, care should be taken not to polish this material too excessively.

1.2311 Chemical nickel plating

This process involves applying a nickel-phosphorus coating to the surface of the material by chemical reduction without the use of electricity. This method is often used when workpieces have recesses or holes that are difficult to reach with other coating methods. The nickel layer applied using this method is hard and offers good protection against wear.

1.2311 Laser surface hardening

Laser surface hardening (surface layer hardening) can harden the surface in specific areas without affecting the properties of the rest of the workpiece. This is achieved using a high-power laser that heats specific areas of the surface. These areas then cool down quickly on their own, forming a hard martensite. This gives the workpiece better wear resistance in these areas, while the rest of the material retains its ductility.

Due to the selective and superficial heating, quenching is not necessary, which prevents hardness distortion and generally eliminates the need for post-processing.

1.2311 Processing

1.2311 dimensional changes

Wenn diese Stahlgüte bei einer Härtetemperatur von 840 °C in Öl abgeschreckt wird, dehnt sich das Material normalerweise um 0,0762 mm/mm aus. Die Maßänderungen während der Wärmebehandlung werden jedoch weitgehend von Größe und Form der Teile beeinflusst. Um Maßänderungen zu minimieren, ist es wichtig, eine gute Vorgehensweise während der Wärmebehandlung einzuhalten.

1.2311 Forging

Tool steel can be forged in a temperature range of 900–1090 °C. Forging below a temperature of 870 °C should be avoided and, if necessary, the material should be brought up to forging temperature again.

1.2311 Welding

Material 1.2311 can be welded using all conventional methods. Heat the material to a temperature of 315–370 °C. Do not allow the welding temperature to fall below 315 °C. The filler materials should be matched to the hardness of the base metal. Cool slowly to 40–65 °C, then reheat to a temperature of 540 °C for one hour per 25 mm of weld depth, not exceeding 565 °C, as this can lead to a loss of hardness. If possible, use double tempering.