1.2312 - AT A GLANCE

What kind of steel is the 1.2312?

The 1.2312 is a cold work and plastic mould steel, that is even pre-hardened and with added sulphur still easely machined. In addition this steel grade can be polished. For an even higher surface requirements please use the 1.2311 which is pre-hardened and can be used in its delivery condition.

Properties

The 1.2312 has a good combination of toughness, hardness and machinability. This combination makes this steel grade perfect for many applications.

- Pre-hardened tool steel

- Cold work steel

- Good machinabilty due to the added sulphur

- limited polishability

- Etchability

- High through-hardenability and uniform component strength

- Further hardening is not intended

- Nitridable

- EDM machinable

Applications

Tool steel 1.2312 is versatile and can be easily machined even in the tempered state due to its sulphur content.

- Mechanical engineering

- Jigs

- Base plates

- Assembling parts

- Moulding frames

- Plastic moulds

- Plastic processing

- Die casting moulds

- Hydroforming tools

- Recipient sleeves

- Folding bars

- Tool holders

1.2312 Standard values

Chemical composition:

| C | Si | Mn | P | S | Cr | Mo |

|---|---|---|---|---|---|---|

| 0.35 - 0.45 | 0.3 - 0.5 | 1.4 - 1.6 | 0.0 - 0.03 | 0.05 - 0.1 | 1.8 - 2.0 | 0.15 - 0.25 |

Chemical designation:

40CrMnMoS8-6

Working hardness:

approx. 32 HRC (delivery condition) up to 50 HRC

Delivery condition:

max. 325 HB

1.2312 Physical Properties

What group of steel does the 1.2312 belong to?

- Tool steel

- Plastic mould steel

- Cold work steel

Is the 1.2312 a stainless steel?

The 1.2312 has a chromium content of 1,8 – 2 %, whith a mass fraction of at least 10,5 % a steel can be classified as a stainless steel. Therfore the 1.2312 is not a stainless steel.

Is the 1.2312 corrosion resistant?

To be fully corrosion resistant a steel has to have a minimum mass fraction of 10,5 % chromium. With a mass fraction of 1,8 – 2 % of chromium the 1.2312 can rust in corrosive environments.

Is the 1.2312 magnetisable?

The 1.2312 is a ferromagnetic metal, it is magnetisable and it is possible to machine this material on machines with magnetic clamping.

1.2312 Wear resistance

This cold work steel has a good wear resistance and receives on a scale where 1 is low and 6 is high a 3 for its wear resistance.

1.2312 Technical Properties

1.2312 Working hardness

Steel grade 1.2312 has a working hardness on delivery of approx. 32 – 50 HRC.

1.2312 Density

The typical density at room temperature for tool steel 1.2312 is at 7,85 g/cm3.

1.2312 Tensile strength

The 1.2312 has a tensile strength of approx. 1100 N/mm2. To receive this value a sample will be used for a tensile test to see how much stresses can be loaded until it elongates and then breaks.

1.2312 Yield strength

The yield strength shows how much stress is needed before the material starts to plastically deforms and when the point is reached when the material does not return into its original form after the stress is removed.Then it either stays deformed or even breaks.

The yield strength for tool steel is in a range of 950 – 1100 N/mm2.

1.2312 Machinability

For its machinability the 1.2312 receives a 5 on a scale where 1 is low and 6 is high.

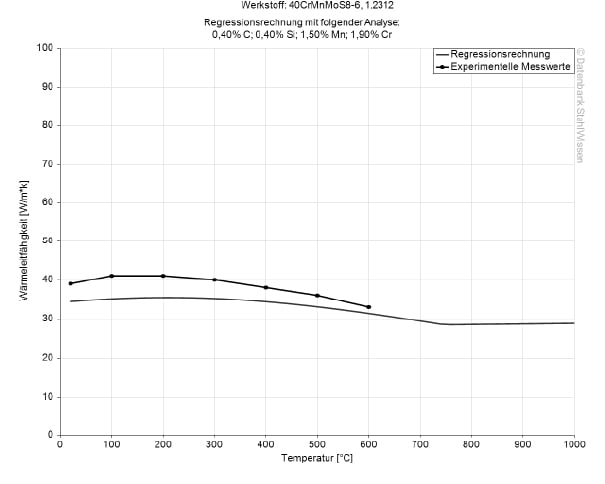

1.2312 Heat conductivity

The following table shows the heat conductivity for tool steel 1.2312 at various temperatures.

Heat conductivity

Value annealed (W/m*K)

Value pre hardened (W/m*K)

At a temperature of

40.2

39.8

100 °C

40.9

40.4

150 °C

40.3

40.4

200 °C

40.0

39.9

250 °C

39.0

39.0

300 °C

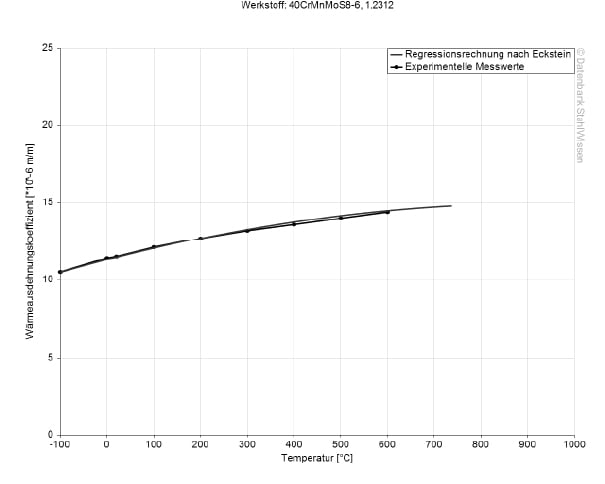

1.2312 Thermal expansion coefficient

The following table shows the expansion or contraction at different temperatures. This can be very improtant when working with high or ever changing temperatures.

Medium thermal expansion coefficient

Value annealed

10-6m/(m*K)

Value pre hardened

10-6m/(m*K)

At a temperature of

12.5

12.3

20 – 100 °C

13.4

13.0

20 – 200 °C

13.9

13.7

20 – 300 °C

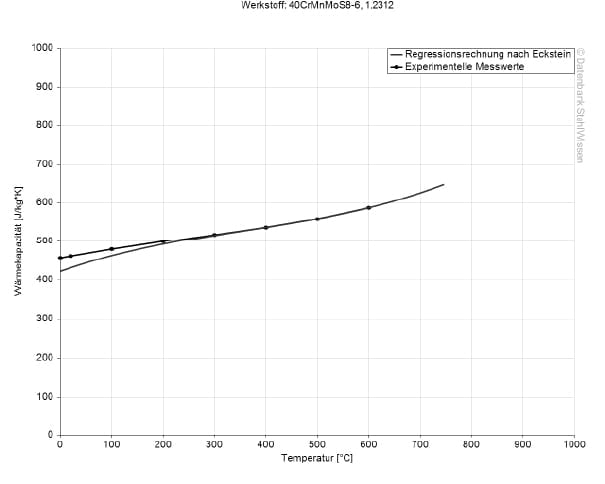

1.2312 Specific heat capacity

At room temperature the specific heat capacity of the 1.2312 is at 0,46 J/kg*K. This value shows how much heat is needed to heat a specific amount of material by 1 Kelvin.

1.2312 Specific electrical resistance

The following table shows the specific electrical resistance. Electrical conductivity is the reciprocal of electrical resistivity.

Specific electrical resistivity

Value (Ohm*mm²)/m

At a temperature of

0.9

20 °C

PREMIUM QUALITY –

OUR HIGHEST STANDARD!

1.2312 Procedure

1.2312 Heat treatment

A heat treatment for this steel grade is not intended as the 1.2312 is delivered in the pre hardened condition. Should a heat treatment be unavoidable please follow the steps below.

A heat treatment determines the material properties and should be carried out with care. Properties such as strength, toughness, surface hardness and temperature resistance are determined, which in turn can extend/improve the service life of parts, tools and components.

Heat treatment includes solution heat treatment, soft annealing, normalising, stress-relief heat treatment, but also tempering, hardening and quenching.

1.2312 Annealing

Heat the material evenly to a temperature of 710 – 740 °C and hold for approx. 4 – 6 hours. Cooling is done slowly in the furnace to finish the annealing process.

1.2312 Stress relieving

To relieve residual stresses heat the material evenly to a temperature of 580 – 620 °C and hold for 2 – 3 hours. To finish the process the material stay to cool down slowly in the furnace.

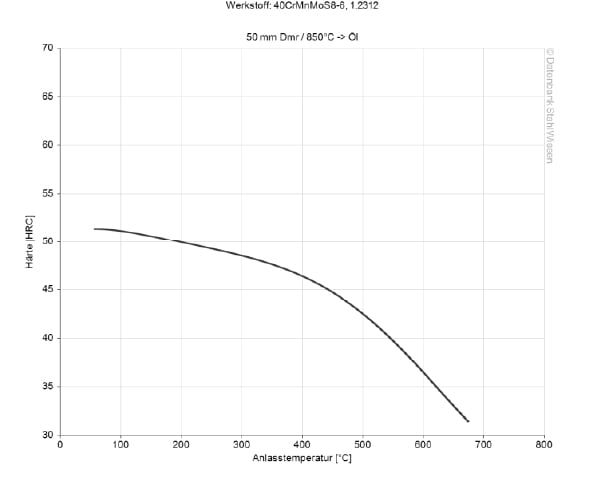

1.2312 Tempering

Choose the tempering temperature for needed hardness and properties.

When tempering residual stresses are reduced and the balance of hardness and toughness restored.

For further information see the graphic below:

1.2312 Hardening

To harden the 1.2312 heat the material evenly to a temperature of 840 – 870 °C and quench it afterwards.

1.2312 Quenching

After hardening the material is quenched in the following media:

- Oil

- Hot basin (180 – 220 °C)

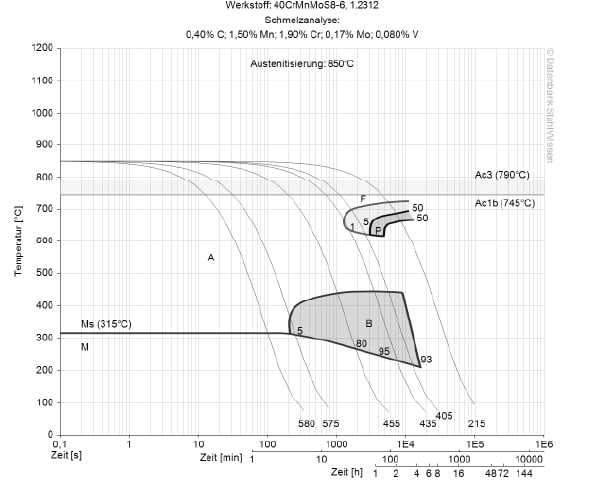

1.2312 Continuous TTT-diagram

The TTT-diagram usually shows micro-changes over time at different temperature. These are important in heat treatment as they provide information on the optimal conditions for processes such as hardening, annealing and normalising.

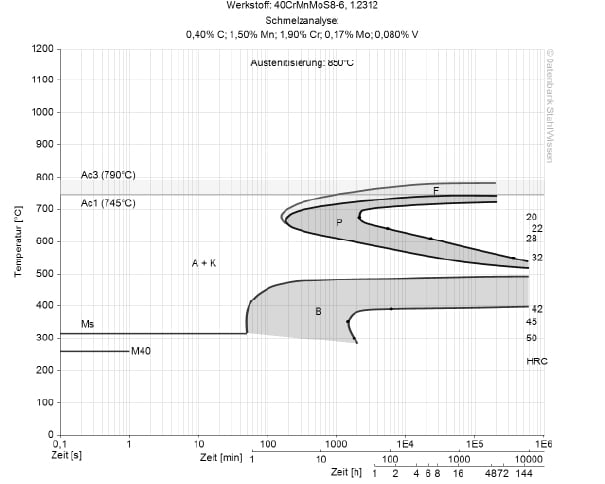

1.2312 Isothermal TTT-diagram

This diagram shows the structural changes at micro level over time at a constant temperatur. It shows at which temperatures after what time the different phases like perlit, martensite or bainite start to form.

1.2312 Surface treatment

1.2312 Nitriding

This process diffuses nitrogen into the surface of the 1.2312. This builds a hard surface, better wear resistance and can improve/extend the service life of tools and components.

1.2312 Processing

1.2312 Electrical Discharge Machining (EDM)

In general, a material is eroded to produce workpieces from a single piece. Erosion can be used to produce dies or more complex shapes. There are various methods of eroding different materials, such as wire erosion, spark erosion or sinker erosion.

1.2312 Forging

To forge the 1.2312 the tool steel is heated to a temperature of 1050 – 1080 °C. The forging temperature should not drop below a temperature of 930 °C. If needed the work pieces should be brought back to temperature as often as needed. After forging the 1.2312 should receive a post heat treatment.

1.2312 Welding

Preheat the 1.2312 to a temperature of 300 – 400 °C then take it up to a welding temperature of 400 – 500 °C. To avoid cracks and internal stresses let the material cool slowly in the furnace when finishe welding. To reduce residual stresses and to adjust the mechanical properties to the base material a heat treatment is recommended.

The weld should be checked for cracks and inclusions to secure the structural integrity of the workpiece.