1.2316 - AT A GLANCE

What kind of steel is the 1.2316?

Steel grade 1.2316 is a high alloyed chromium steel which is often used for chemically agressive plastic materials like PVC for example.

Properties

Tool steel 1.2316 (X38CrMo16) is not only a good choice in many industries and demanding applications for its corrosion resitance. Because of the added molybdenum offers assistance to its hardenability and wear resistance as well as its longevity and performance. These and many other properties make this steel a very good choice when precision is the main factor.

- Tool steel

- Plastic mould steel

- Chromium steel

- Tempered

- Corrosion resistant

- Good thermal resistance

- Good wear resistance

- Excellen hardenability

- High resistance to dampness

- High resistance to aggressive chemicals

Applications

Due to its good technical properties the 1.2316 find it use in many industries.

- Mechanical engineering

- marine engineering

- Apparatus engineering

- Plastic processing

- Plastic moulds

- Extrusion tools

- Press moulds

- Fitting tools

- Shafts

- Spindels

- Bolts

- Pistons

- Valves

- Steam valves

- Water valves

- Beater bars

- Fittings parts

- Pump construction

- Pump rods

- Compressor construction

- Compressor parts

- Surgical instruments

- Medical components that require regular sterilisation

- . Machines that require regular cleaning

1.2316 Standard values

Chemical composition:

| C | Si | Mn | P | S | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|

| 0.33 - 0.45 | 0.0 - 1.0 | 0.0 - 1.5 | 0.0 - 0.03 | 0.0 - 0.03 | 15.5 - 17.5 | 0.8 - 1.3 | 0.0 - 1.0 |

Chemical designation:

X38CrMo16

Working hardness:

approx. 30 HRC (delivery condition)

up to 48 HRC

Delivery condition:

max. 325 HB

1.2316 Physical properties

What group of steel does the 1.2316 belong to?

- Tool steel

- Plastic mould steel

- Stainless steel, corrosion resistance

- Stainless steel, acid resistance

- Chromium steel

Is the 1.2316 a stainless steel?

With a chromium content of 15.5–17.5%, 1.2316 is a stainless steel in the classic sense.

Is the 1.2316 corrosion resistant?

Yes, with a mass fraction of 15.5–17.5%, the 1.2316 is corrosion-resistant.

1.2316 General corrosion resistance

Due to its chromium content, 1.2316 is coated with a passive and self-healing chromium layer. This layer gives it corrosion resistance in atmospheric and slightly aggressive environments, weak acids and alkalis, and humid environments. Its molybdenum content improves its resistance to pitting and crevice corrosion in chloride-containing environments.

Is the 1.2316 magnetisable?

1.2316 is a ferromagnetic material and is magnetisable.

1.2316 Wear resistance

The material 1.2316 receives a 3 for its wear resistance on a scale where 1 is low and 6 is high.

1.2316 Technical properties

Is the 1.2316 a knife steel?

With its corrosion resistance, toughness and sharpenability, 1.2316 can be used as knife steel. Its hardness is sufficient for this purpose when hardened to maximum hardness. For better cutting performance, as with high-quality knives, a steel with higher hardness should be used.

1.2316 Working hardness

1.2316 achieves a working hardness of approx. 30 HRC – 48 HRC on delivery.

1.2316 Density

The typical density of stainless steel 1.2316 is 7.7 g/cm³ at room temperature.

1.2316 Tensile strength

The 1.2316 has a tensile strength of approx. 1100 N/mm2. To achieve this value, a tensile test is carried out to show how much force is required to stretch or elongate a sample before it breaks.

1.2316 Machinability

On a scale where 1 is low and 6 is high, the 1.2316 receives a 2 for its machinability.

1.2316 Heat conductivity

The thermal conductivity for 1.2316 is 23.5 W/(m*K) at a temperature of 23 °C.

Heat conductivity

Value W/(m*K)

At a temperature of

23.5

23 °C

24.2

150 °C

24.3

300 °C

24.4

350 °C

24.1

400 °C

23.2

500 °C

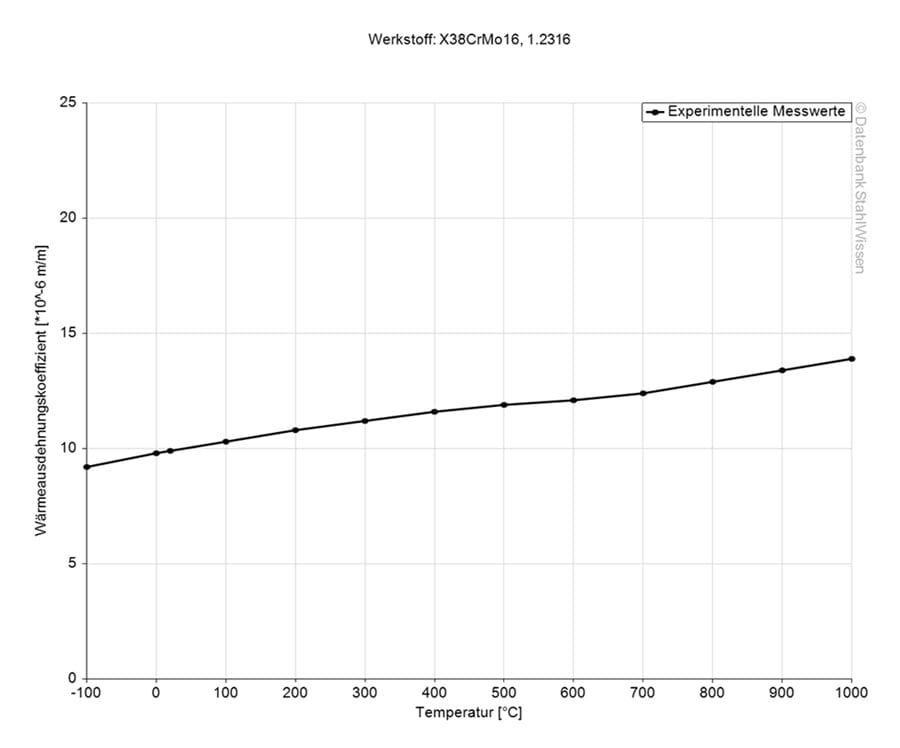

1.2316 Thermal expansion coefficient

The following table shows the expansion or contraction at different temperatures, which can be very important for work at high temperatures or when working with high temperature fluctuations.

Average thermal expansion coefficient

Value 10-6m/(m*K)

At a temperature of

10.5

20 – 100 °C

10.8

20 – 200 °C

11.1

20 – 300 °C

11.3

20 – 350 °C

11.5

20 – 400 °C

11.6

20 – 450 °C

11.7

20 – 500 °C

1.2316 Specific heat capacity

The specific heat capacity of tool steel 1.2316 at room temperature is 0.46 J/kg*K. This value indicates how much heat is required to heat a certain amount of material by 1 Kelvin.

1.2316 Specific electrical resistance

The specific electrical resistance can be found in the following table. Electrical conductivity is the reciprocal of specific electrical resistance.

Specific electrical resistance

Value (Ohm*mm2)/m

At a temperature of

0.6

20 °C

PRECISION!

1.2316 Procedure

1.2316 Heat treatment

1.2316 is supplied pre-tempered; heat treatment is possible but not necessary.

Heat treatment determines the properties of the material. It should therefore always be carried out with care. Properties such as strength, toughness, surface hardness and temperature resistance are determined, which in turn can extend/improve the service life of parts, tools and components.

Heat treatment includes solution annealing, soft annealing, normalising, stress relief annealing, but also tempering, hardening and quenching or tempering.

1.2316 Annealing

For annealing, the 1.2316 is heated evenly to a temperature of 760–800 °C and held at this temperature for approx. 2–4 hours. The workpieces are then cooled in the furnace.

1.2316 Stress relieving

To relieve internal stresses after intensive processing, the material is heated evenly to a temperature of 600 – 650 °C, held at this temperature for at least 4 hours and then cooled in the furnace.

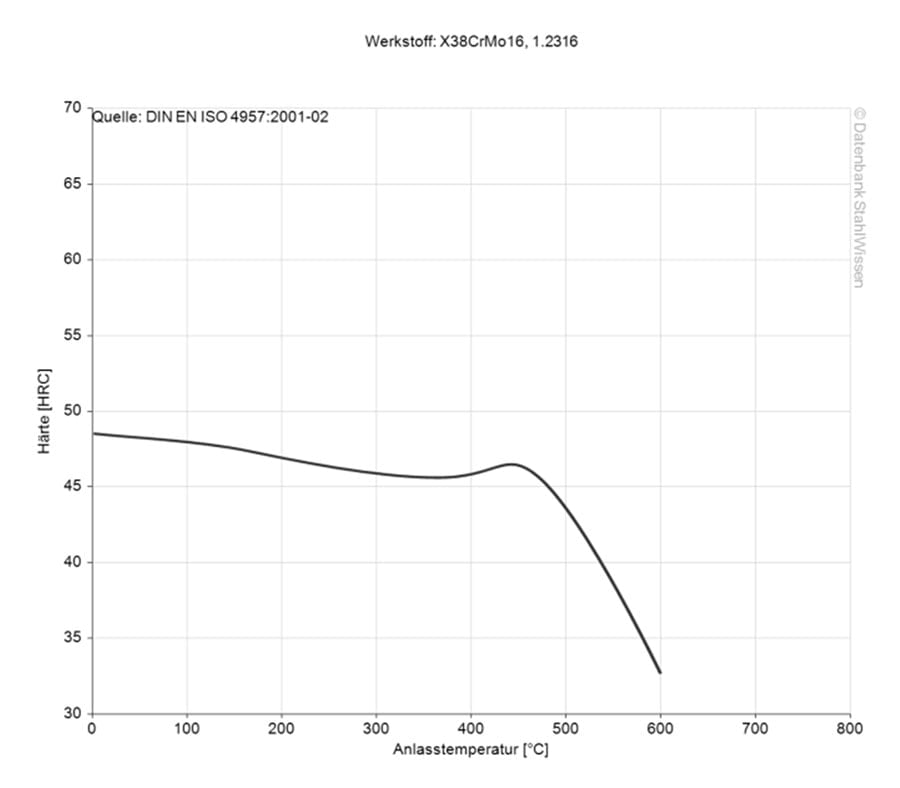

1.2316 Tempering

The tempering temperature is selected according to the desired hardness and properties.

Tempering reduces internal stresses and specifically balances the strength and toughness of the material.

Further information can be found in the diagram below:

1.2316 Hardening

To harden material 1.2316, it is heated evenly to a temperature of 1020 – 1050 °C and held there for approx. 15 – 30 minutes. The material should then be quenched.

1.2316 Quenching

1.2316 can be quenched in the following media:

- Oil

- Hot bath (500 – 550 °C)

- Pressurised gas (N2)

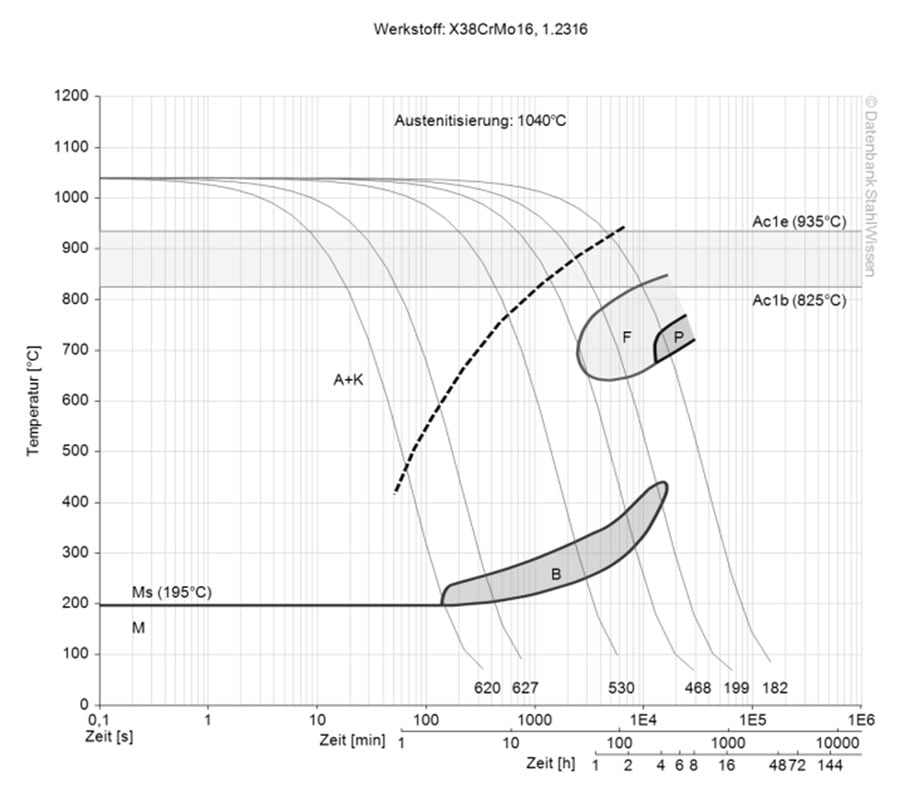

1.2316 Continuous TTT-Diagram

This diagram shows micro-changes over time at different temperatures. These are important in heat treatment, as they provide information about the optimal conditions for processes such as hardening, annealing and normalising.

1.2316 Surface treatment

1.2316 Nitriding

During nitriding, nitrogen is diffused into the material surface to achieve higher surface hardness with better wear resistance, improved corrosion resistance and reduced friction.

1.2316 Passivation

Passivation increases corrosion resistance. The surface is treated with an acid solution to remove free iron from the surface.

1.2316 Polishing

Polishing can smooth the surface and give the material a high gloss finish. This can increase corrosion resistance, as a smooth surface reduces the adhesion of contaminants such as dust or bacteria.

1.2316 PVD and CVD coating

Both processes, PVD and CVD coating, apply a thin layer to the surface of the material. This thin, hard layer gives the material a wear-resistant coating.

- PVD – physical vapour deposition

- CVD – chemical vapour deposition

1.2316 Processing

1.2316 Electrical Discharge Machining (EDM)

Erosion can be used to achieve various surface finishes, but it is primarily used to produce complicated shapes, small details and complex geometries in hard materials. As the 1.2316 material is in the upper hardness range, erosion can be used successfully. When selecting the electrodes, dielectric fluid and cutting speed, the surface quality and subsequent application should be taken into account.

1.2316 Machining allowance / dimensional changes

The 1.2316 has good dimensional stability. With controlled heat treatment and uniform cooling, as well as stress relief, dimensional stability remains optimised and the 1.2316 is a grade that can be used in areas requiring high precision.