1.2344 ESR - AT A GLANCE

What kind of steel is the 1.2344 ESR?

The 1.2344 ESR Steel is a hot work steel. It can be water cooled, oil or air hardened and has a good toughness. The 1.2344 ESR is a 5% chromium tool steel that hardens in air and is versatile enough for a broad range of hot and cold work uses. The added vanadium increases the resistance to abrasion and imparts superior properties at elevated temperatures.

Tool Steel 1.2344 ESR is often used in cold work tools because of its exceptional toughness, even though it might slightly reduce wear resistance. Apart from its high temperaturr resistance and thermal cracking resistance, it also has high polishability and is suitable for lens and cutlery molds.

Properties

Tool Steel 1.2344 ESR has some advantages and disadvantages. Although it has a certain corrosion resistance, it should be well cared for to prevent rust. The 1.2344 ESR does not lend itself for making knives as it cannot hold its sharpness at the cutting edge, even though its hardness makes it easy to resharpen.

Although this steel is better suited for hot work, it can also be cold worked. The 1.2344 ESR has high temperature stability, good resistance to thermal fatigue and good toughness and wear resistance.

- Good high-temperature strength

- High hot wear resistance

- High thermal shock resistance

- Very good toughness

- Can be easily eroded and nitrided

- Water coolable

- Fire crack resistant

Applications

The 1.2344 ESR has a multitude of good properties which makes this tool steel not only a good choice for high temperatures but in combination with its thermal fatigue and abrasion resistance can be used for casting and extrusion tools, as well as for dies, hot shear blades and stamping tools to name just a few. With its good resistance to thermal fatigue, erosion and wear, it is ideal for plastic moulds.

- Forging tools and dies

- Hot shear knives

- Hot extrusion tools

- Extrusion press tools

- Press tools

- Block receivers

- Die casting tools

- Light metal die casting

- Press mandrels

- Press dies

- Piecer plugs

- Screw production

- Rivet production

- Bolts production

- Ejectors

- Plastic molds

1.2344 ESR Standard values

Chemical composition:

| C | Si | Mn | P | S | Cr | Mo | V |

|---|---|---|---|---|---|---|---|

| 0.35 - 0.42 | 0.8 - 1.2 | 0.25 - 0.5 | 0.0 - 0.03 | 0.0 - 0.02 | 4.8 - 5.5 | 1.2 - 1.5 | 0.85 - 1.15 |

Chemical designation:

X40CrMoV5-1

Working hardness:

50-56 HRC

Delivery condition:

max. 229 HB

1.2344 ESR Physical properties

What group of steel does the 1.2344 ESR belong to?

- Tool steel

- Hot work steel

- Plastic mould steel

Why ESR material?

Electro-slag remelting, also known as electro-flux remelting, is a process by which steel is remelted and passed through a slag that removes debris and impurities from the steel. What remains is a steel with a higher degree of purity and a finer, homogeneous structure. The reduction of impurities in the steel gives it greater integrity, as there are fewer weak points. ESR steel can exhibit better mechanical properties, such as higher tensile strength, yield strength, toughness, wear resistance, better surface finish and longer tool life.

Especially for 1.2344 ESR, an already corrosion-resistant steel, the ESR process further improves corrosion resistance by reducing inclusions and other impurities.

Is the 1.2344 ESR a stainless steel?

Although 1.2344 ESR contains a mass fraction of 4.8–5.5% chromium, it is not stainless steel in the traditional sense. Stainless steel contains a minimum of 10.5% chromium.

Although 1.2344 ESR offers a certain degree of corrosion resistance, if corrosion resistance is a key requirement, it is advisable to choose a stainless steel grade or apply a protective coating.

Is the 1.2344 ESR magnetisable?

Yes, as a ferrous metal, 1.2344 ESR can be magnetised. Grinding, milling and eroding can be carried out on machines with magnetic adhesion, for example.

1.2344 ESR Hot work

Hot work steel, such as 1.2344 ESR, can be continuously exposed to high temperatures. It has high strength, hardness, thermal stability, toughness and wear resistance for a longer service life.

1.2344 ESR Cold work

Cold working the 1.2344 ESR material is easier in the annealed state. Heat treatment is challenging due to its hardness, and the parts can become hardened, which in turn can lead to breakage and wear. In order to relieve the stresses introduced and give the workpieces their final properties, they should then be heat treated.

1.2344 ESR Wear resistance

On a scale where 1 is low and 6 is high the 1.2344 ESR receives a 3 for its wear resistance.

1.2344 ESR Technical properties

1.2344 ESR Working hardness

Die Arbeitshärte für die Güte 1.2344 ESU liegt bei 50 – 56 HRC.

1.2344 ESR Density

The density for tool steel 1.2344 ESR at room temperature is approx. 7,74 g/cm³.

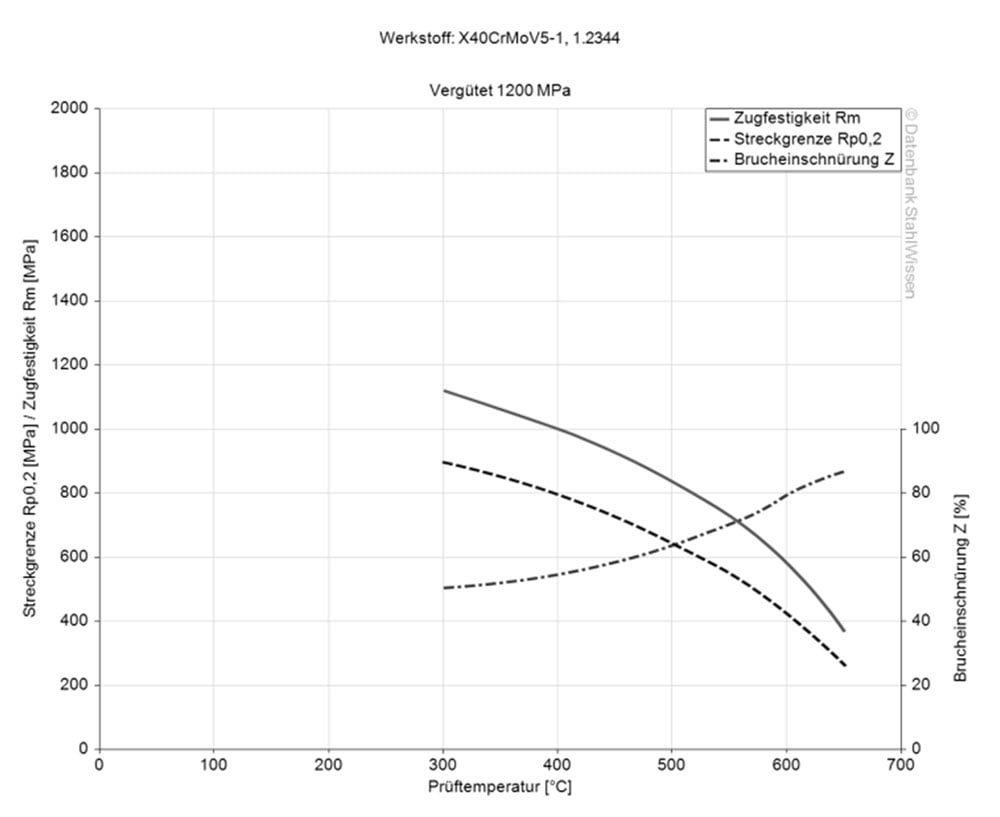

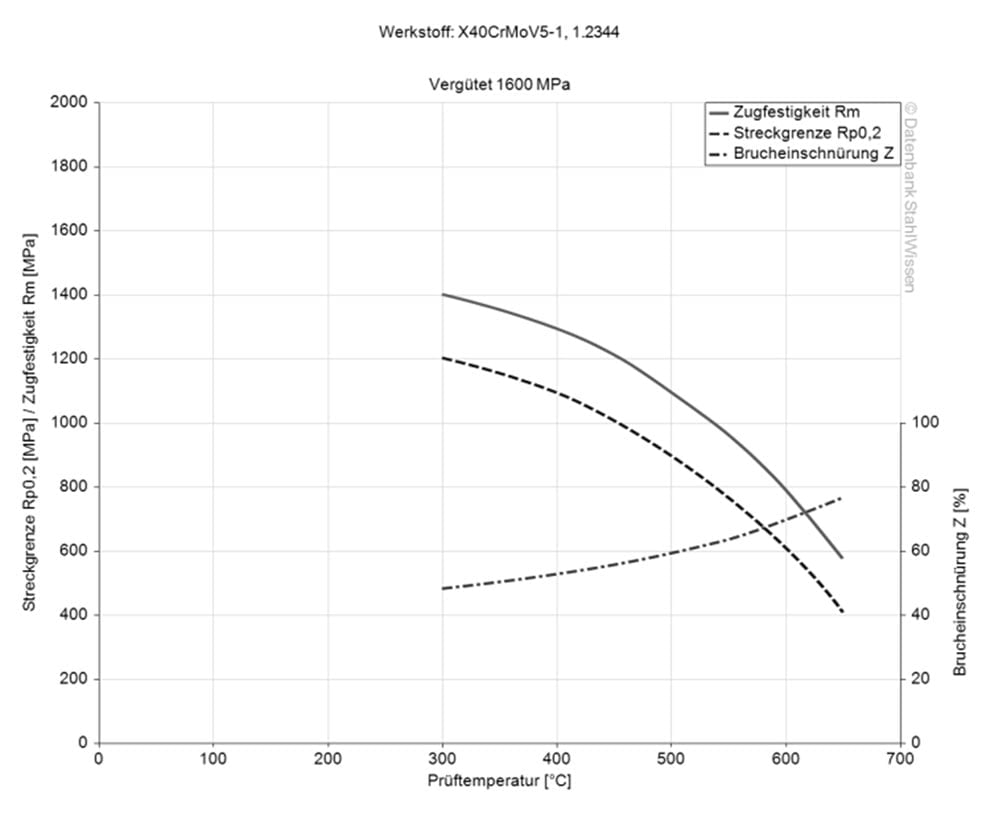

1.2344 ESR Tensile strength

The 1.2344 ESR has a tensile strength of approx. 770 N/mm² in its delivery condition. To determine this value, a material sample is subjected to a tensile test to determine how much force is required to stretch or elongate the sample before it breaks.

1.2344 ESR Yield strength

The yield strength indicates how much stress a material can withstand before it becomes irreversibly deformed. Before reaching this point, the 1.2344 ESR material will return to its original shape when the stress is removed. After this point, the material remains deformed or even breaks. The yield strength for 1.2344 ESR tool steel is approximately 1650 N/mm2.

1.2344 ESR Machinability

On a scale where 1 is low and 6 is high, material 1.2344 ESR receives a 4 for its machinability.

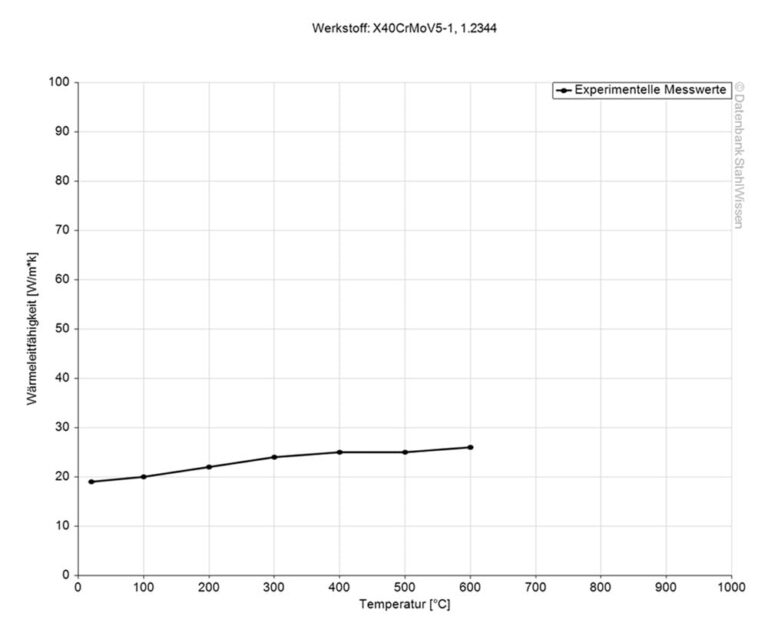

1.2344 ESR Heat conductivity

The following table shows the thermal conductivity of material 1.2344 ESR in its annealed and hardened state.

Heat conductivity

W/(m*K)

W/(m*K)

At a temperature of

27.2

25.5

20 °C

30.5

27.6

350 °C

33.4

30.3

700 °C

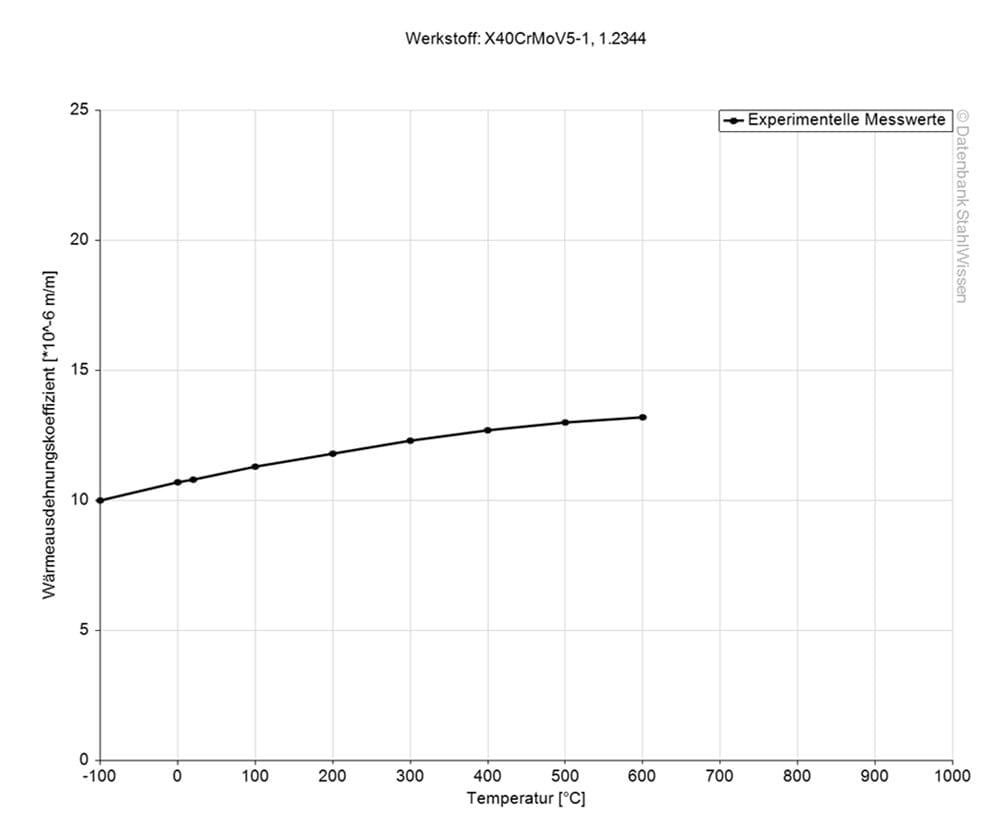

1.2344 ESR Thermal expansion coefficient

This diagram shows how much material 1.2344 ESR expands or contracts when exposed to temperature changes. This information can be important when tools are exposed to high or fluctuating temperatures.

Medium thermal expansion coefficient

Value 10-6m/(m*K)

At a temeprature of

10.9

20 – 100 °C

11.9

20 – 200 °C

12.3

20 – 300 °C

12.7

20 – 400 °C

13.0

20 – 500 °C

13.3

20 – 600 °C

13.5

20 – 700 °C

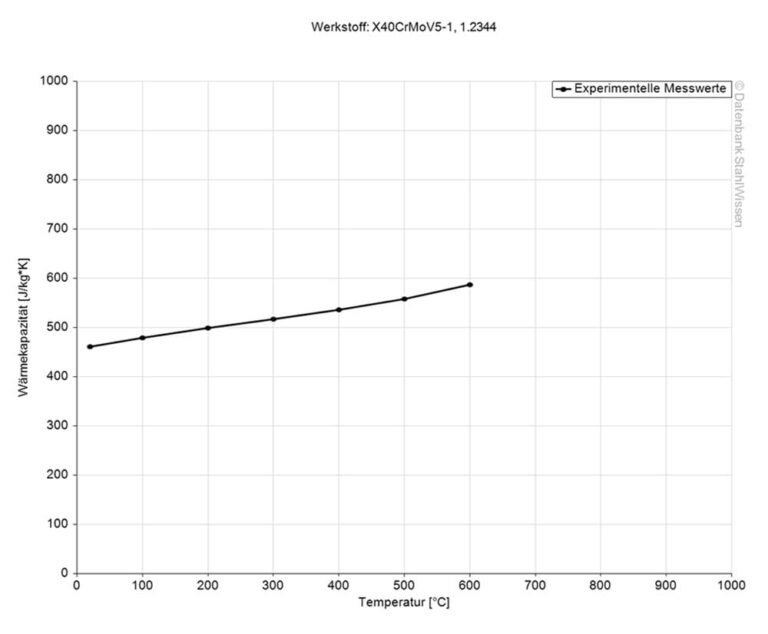

1.2344 ESR Specific heat capacity

The specific heat capacity of 1.2344 ESR at room temperature is 0.46 J/kg*K.

The specific heat capacity is a physical property of 1.2344 ESR and indicates how much heat is required to heat a specific amount of material by 1 Kelvin.

1.2344 ESR Specific electrical resistance

The temperature dependent material constant (specific electrical resistance) can be found in the following table.

Electrical conductivity is the reciprocal of the specific electrical resistance.

Specific electrical resistance

Value (Ohm*mm2)/m

At a temperature of

~ 0.543

~ 20 °C

~ 0.638

~ 100 °C

~ 0.705

~ 200 °C

~ 0.782

~ 300 °C

~ 0.868

~ 400 °C

~ 0.96

~ 500 °C

~ 1.06

~ 600 °C

MAXIMUM FLEXIBILITY –

THAT IS OUR €co-Präz®!

1.2344 ESR Procedure

1.2344 ESR Heat treatment

The heat treatment process determines the properties of the material. It should therefore always be carried out with care. Properties such as strength, toughness, surface hardness and temperature resistance are determined, which in turn can extend/improve the service life of parts, tools and components.

Heat treatment includes solution annealing, soft annealing, normalising, stress relief annealing, but also tempering, hardening and quenching or tempering.

1.2344 ESR Annealing

To prevent surface damage, 1.2344 ESR should be annealed in a neutral atmosphere or in a suitable container using neutral annealing charcoal.

For annealing, 1.2344 ESR is heated slowly and evenly to a temperature of 750–800 °C.

The temperature is then reduced by approx. 10–20 °C per hour to 600 °C, after which the material can cool further in air.

1.2344 ESR Stress relieving

After rough machining, or in case of extensive machining, stress relief annealing is required for 1.2344 ESR in order to prevent deformation caused by induced stresses. The tool steel is stress relief annealed at a temperature of 600 – 650 °C.

The temperature is maintained for 1–2 hours in a neutral atmosphere and then cooled in a controlled manner in air. Controlled cooling is important to prevent new stresses from building up.

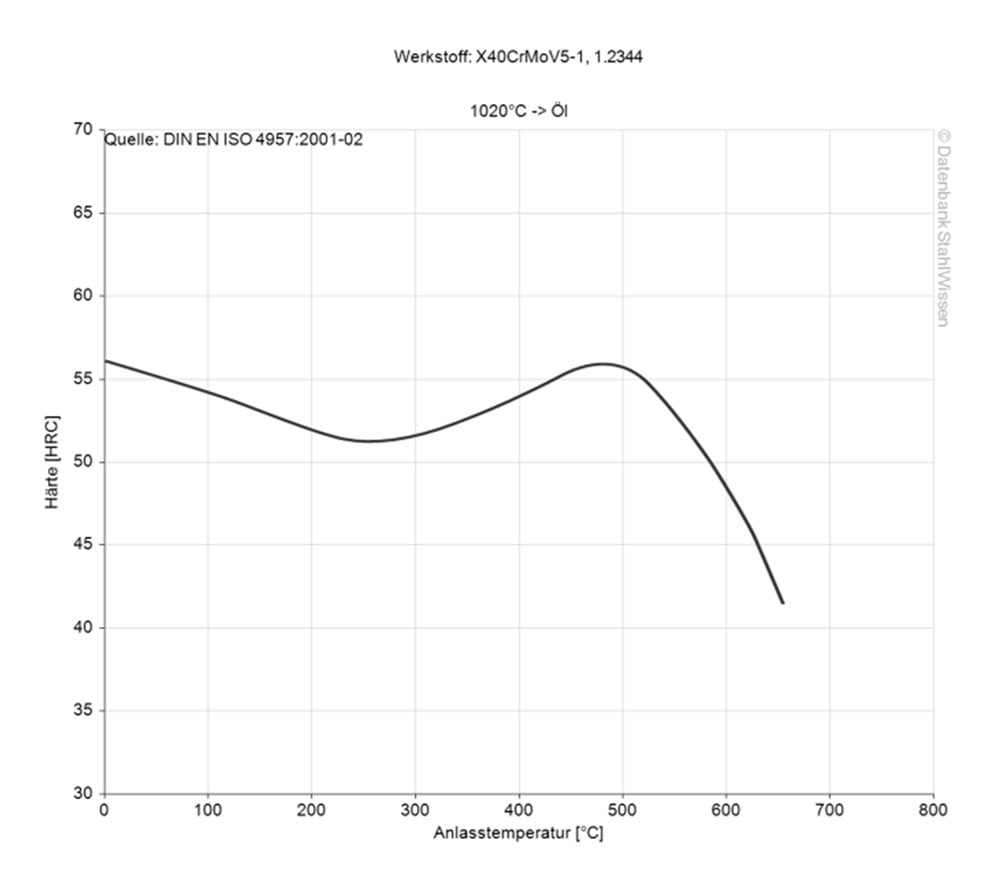

1.2344 ESR Tempering

Immediately after hardening, the material is slowly brought to the tempering temperature and held there for at least 1 hour per 25 mm thickness. The tempering temperature should be at least 10 °C above the expected working temperature of the tool.

Workpieces should be tempered twice; a third tempering process can be beneficial for reducing stress in the workpiece.

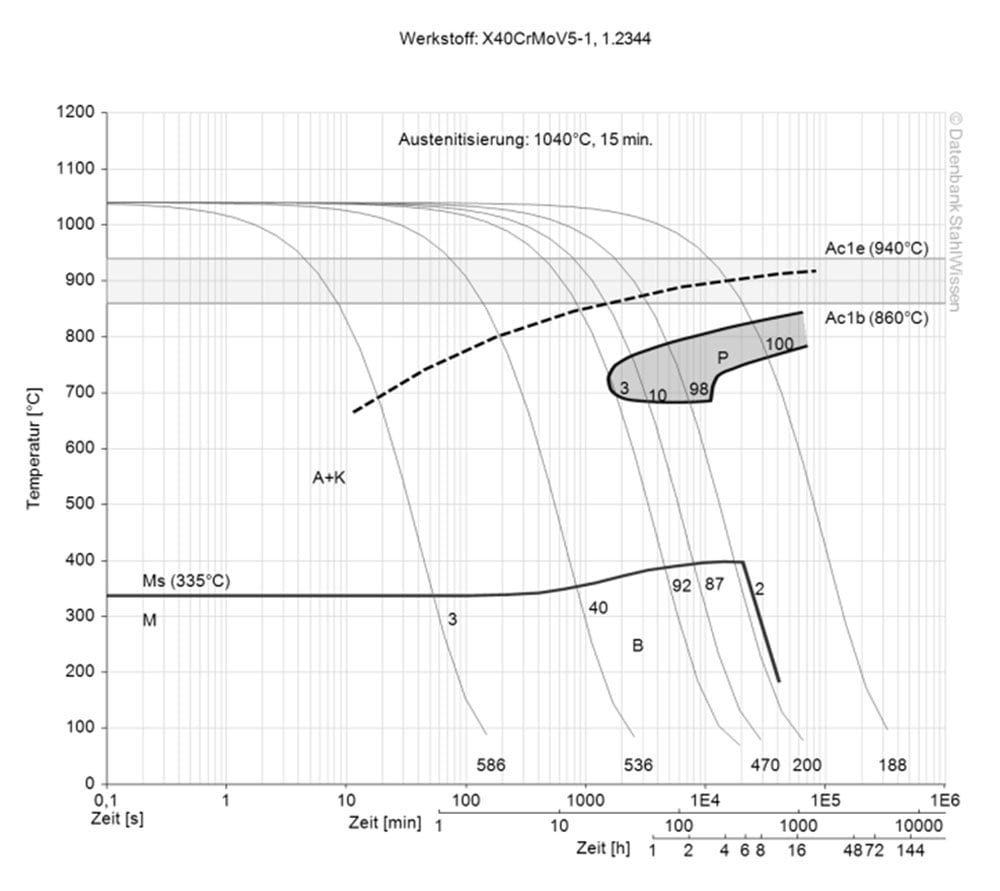

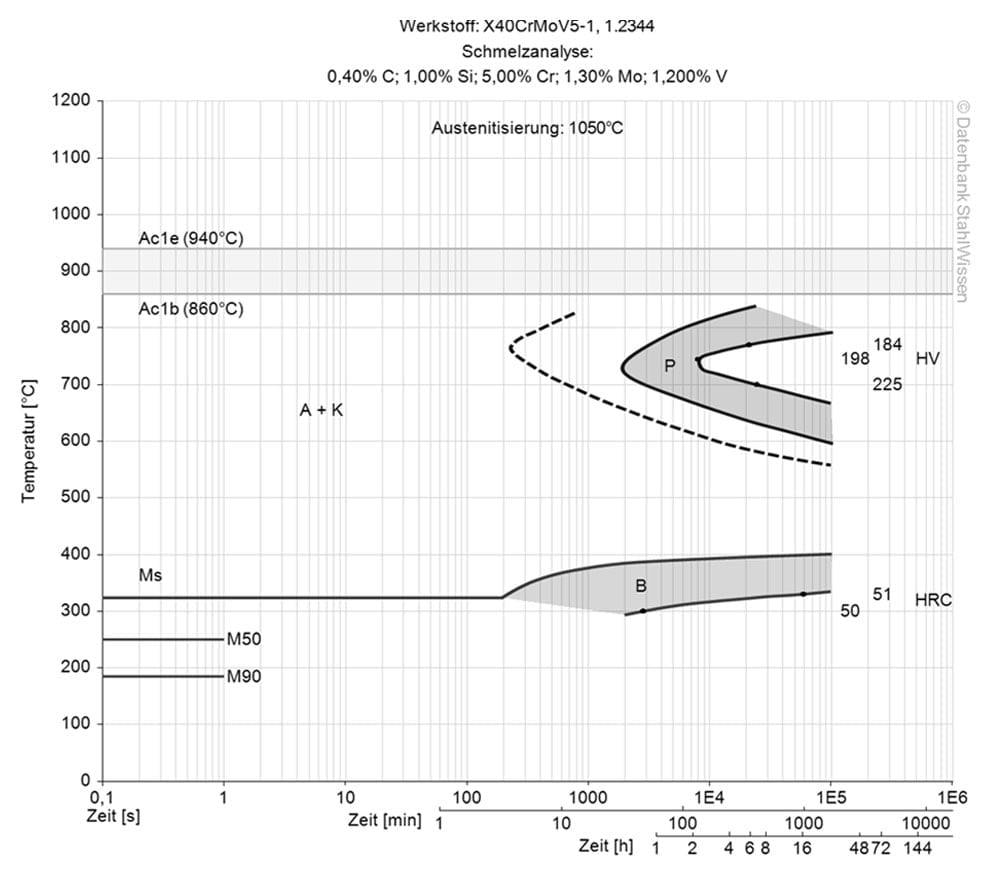

1.2344 ESR Hardening

Hardening tool steel 1.2344 ESR gives it better properties.

To control decarburisation, use a controlled atmosphere furnace or pack the 1.2344 ESR in an inert material. Heat it evenly to a temperature of 1020 – 1060 °C, hold the temperature for 15 – 30 minutes, quench the material and then let it cool directly.

1.2344 ESR Quenching

The 1.2344 ESR is usually cooled in air, although it can also be cooled with other substances. Factors such as application, shape and size of the workpieces should be taken into account when choosing the cooling method.

- Air

- Oil

- Vacuum

- Hot bath

1.2344 ESR Continuous TTT-Diagram

This diagram shows micro-changes over time at different temperatures. These are important in heat treatment because they provide information about the optimal conditions for processes such as hardening, annealing and normalising.

1.2344 ESR Isothermal TTT-diagram

This diagram shows the structural changes at micro level over time at a constant temperatur. It shows at which temperatures after what time the different phases like perlit, martensite or bainite start to form.

1.2344 ESR Surface treatment

The following treatments are just an example for the many surface treatments which can be used for the 1.2344 ESR. The choice of surface treatment depends on the application the work piece should is being used for after.

1.2344 ESR Nitriding

To improve wear resistance and fatigue strength, grade 1.2344 ESR can be nitrided. This process involves introducing nitrogen into the surface, which results in a certain degree of corrosion resistance, but can also reduce the need for frequent lubrication of moving parts.

1.2344 ESR Carbonitriding / Case hardening

Although this process is not as commonly used for this grade as nitriding, it introduces carbon into the material surface and gives it additional surface hardness with a tough core.

1.2344 ESR Black oxide coating or blueing

During this process, workpieces and tools are given a black mixed oxide coating that provides a certain degree of corrosion protection. This process is also used to give workpieces an aesthetic appearance, but also to give workpieces that are exposed to light a surface with low reflectivity, for example.

1.2344 ESR PVD and CVD coating

To reduce friction and improve wear resistance and corrosion resistance, 1.2344 ESR can be coated using the PVD (Physical Vapour Deposition) or CVD (Chemical Vapour Deposition) processes. In both processes, a very thin layer of material is applied to the surface of the workpieces.

1.2344 ESR Processing

1.2344 ESR Electrical Discharge Machining (EDM)

The 1.2344 ESR can be machined by erosion in its annealed or hardened condition.

Tempering after erosion may be necessary, as the heat-affected zones may have different properties to the base material. With the correct settings and under optimal conditions, the 1.2344 ESR tool steel can achieve a very smooth surface through erosion.

1.2344 ESR Dimensional changes

Like other tool steels, tool steel 1.2344 ESR retains its size best when quenched at an exact hardening temperature. If overheated, the material tends to shrink after tempering and should therefore be avoided.

1.2344 ESR Forging

The material is heated slowly and evenly to a temperature of 1035 – 1120 °C. When forging this material, the temperature should not fall below 900 °C; it can be brought back to forging temperature as required.

Cool small and simple parts slowly in lime. Larger parts should be cooled evenly to a temperature of 790 °C in a heated furnace, then switch off the furnace and allow the parts to cool slowly.

Please note that this is not annealing; annealing should be carried out after the forged parts have cooled down.

1.2344 ESR Welding

When welding tool steel, good results can be achieved if the right precautions are taken (increased working temperature, preparation of the joint, choice of welding consumables and welding process). If the workpieces are polished or photo-etched, it is necessary to work with a suitable type of electrode with the appropriate composition.