1.2358 - AT A GLANCE

What kind of steel is the 1.2358?

The 1.2358 (60CrMoV18-5) is a tempered medium alloed tool steel with a focus on cold work. It is possible to use this steel at low temperatur impact for hot work tools as well. Due to its high wear resistance and impact toughness the 1.2358 is used for plastic moulds, forming tools and embossing tools.

Properties

The 1.2358 is delivered as tempered tool steel and get used mainly for cold work applications but can also be used for hot work tools if low temperature impacts can be guaranteed. A better service life and performance can be achieved with a surface treatment that can optimise the already available properties.

- Tempered tool steel

- Focus on cold work

- High impact strength

- High wear resistance

- Surface hardenable

- Good through-hardenabilty

- High dimensional stability

- Good polishabilty

- Good weldability

- Etchability

- If the above properties are highly relevant, it can be a substitute for 1.2379, 1.2436 and 1.2083 mod.

Applications

With its high precision, hardness and toughness and all the other good properties of this steel grade the 1.2358 can be used for the following applications.

- Segmented cutting tools

- Shear knives

- Forming tools

- Cold forming tools

- Deep drawing dies

- Cold extrution tools

- Bending tools

- Rollers

- Embossing tools

- Mould tools

- Plastic moulds

- Hot working tools at low temperature stresses

1.2358 Standard values

Chemical composition:

| C | Si | Mn | P | S | Cr | Mo | V |

|---|---|---|---|---|---|---|---|

| 0.58 - 0.62 | 0.2 - 0.5 | 0,7 - 0,9 | 0.0 - 0.03 | 0.0 - 0.03 | 4.3 - 4.7 | 0.4 - 0.6 | 0.2 - 0.3 |

Chemical designation:

60CrMoV18-5

Delivery condition:

max. 325 HB

1.2358 Physical Properties

What group of steel does the 1.2358 belong to?

- Tool steel

- Plastic mould steel

- Cold work steel

- Hot work steel

Is the 1.2358 a stainless steel?

The 1.2358 is not a classical stainless steel, to be classified as a stainless steel the material has to have a mass fraction of at least 10,5 % of chromium.

Is the 1.2358 corrosion resistant?

To be corrosion-resistant, a material must contain at least 10.5% of chromium. With a mass fraction of 4.3–4.7% of chromium, the 1.2358 has a certain degree of corrosion resistance, but is not completely corrosion-resistant like stainless steel, for example.

Ist 1.2358 magnetisable?

As a ferro magnetic material the 1.2358 can be magnetised and can for processing, such as milling or grinding, be clamped onto a magnetic plate.

1.2358 Wear resistance

On a scale where 1 is low and6 is high the 1.2358 receives a 5 for its wear resistance.

1.2358 Technical properties

Is the 1.2358 a knife steel?

The material 1.2358 has properties that are suitable for knives, such as corrosion resistance, hardness, toughness and wear resistance, but it is not typically used as knife steel. Its high hardness can make grinding the cutting edge difficult and its corrosion resistance is lower than that of stainless steels used for knives.

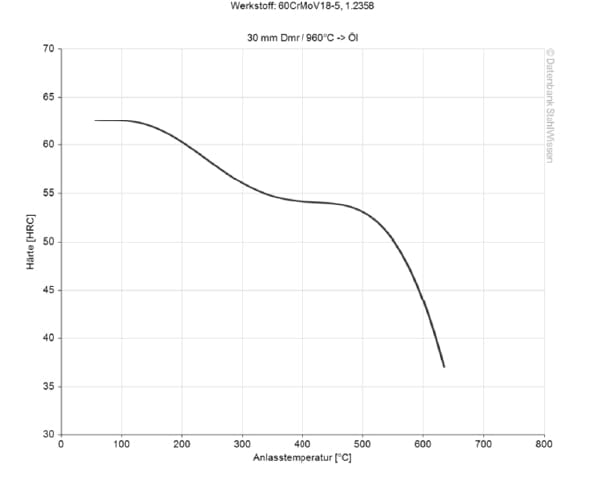

1.2358 Working hardness

The working hardness for tool steel 1.2358 is at approx. 33 HRC (on delivery) up to 60 HRC.

1.2358 Density

The density of tool steel 1.2358 at a temperature of 20 °C is 7.77 g/cm³.

1.2358 Tensile strength

The tensile strength for tool steel 1.2358 is approx. 1100 N/mm2. This value is the result of a tensile test, which shows how much force is required before the material begins to stretch or elongate before it breaks.

1.2358 Heat conductivity

The following table shows the heat conductivity for tool steel 1.2358 at various temperatures.

Heat conductivity

Value tempered

10-6m/(m*K)

At a temperature of

19.4

20 °C

24.6

350 °C

26.3

700 °C

1.2358 Machinability

The 1.2358 receives a 3 for its machinabilty on a scale where 1 is low and 6 is high.

1.2358 Thermal expansion coefficient

The following table shows the expansion or contraction at different temperatures, which can be very important for work at high temperatures or with high temperature fluctuations.

Medium thermal expansion coefficient

Value 10-6m/(m*K)

At a temperature of

11.5

20 – 100 °C

11.8

20 – 200 °C

12.4

20 – 300 °C

12.8

20 – 400 °C

1.2358 Specific heat capacity

The specific heat capacity of the 1.2358 is 0.46 J/kg*K at room temperature. This value indicates how much heat is required to heat a specific amount of material by 1 Kelvin.

USE UP TO 40% LESS MATERIAL = LESS WASTE – THAT IS OUR €co-Präz®!

1.2358 Procedure

1.2358 Heat treatment

Heat treatment is used to determine material properties. It should therefore always be carried out with care. Properties such as strength, toughness, surface hardness and temperature resistance are determined, which in turn can extend/improve the service life of parts, tools and components.

Heat treatment includes solution annealing, soft annealing, normalising, stress relief annealing, but also tempering, hardening and quenching or tempering.

1.2358 Annealing

For annealing, the 1.2358 tool steel is heated evenly to a temperature of 820–860 °C and then cooled in the furnace.

1.2358 Stress relieving

The material 1.2358 is heated evenly to 600 – 650 °C and held at this temperature for 1 – 2 hours. The workpiece is then cooled in the furnace to complete the process.

1.2358 Tempering

To temper, the 1.2358 is heated evenly to a selected temperature. The holding time is at least 2 hours, or 1 hour per 20 mm. The material is then slowly cooled in the furnace or in the air.

1.2358 Hardening

To harden this material evenly heat it to atemperature of 950 – 980°C and hold for 15 to 30 minutes after which it is quenched.

1.2358 Induction hardening (surface hardening)

Induction hardening is a fast, selective and targeted heating of the surface of a workpiece. The surface is heated by the electrical resistance of the material by means of induction (alternating electric voltage).

Various inductors are used to heat the material surface in a focused manner, thereby hardening specific areas of the workpiece. This allows highly stressed areas and even complex geometries to be hardened.

After induction hardening, the material is immediately quenched.

1.2358 Flame hardening (surface hardening)

During flame hardening, the surface is heated to hardening temperature at specific points or across its entire surface using a gas-oxygen mixture and then immediately quenched.

The hardened workpiece is then tempered to adjust the surface hardness and reduce internal stresses.

1.2358 Quenching

The 1.2358 material can be quenched in the following media:

- Oil

- Pressurised gas (N2)

- Air

- Hot bath (500 – 550 °C)

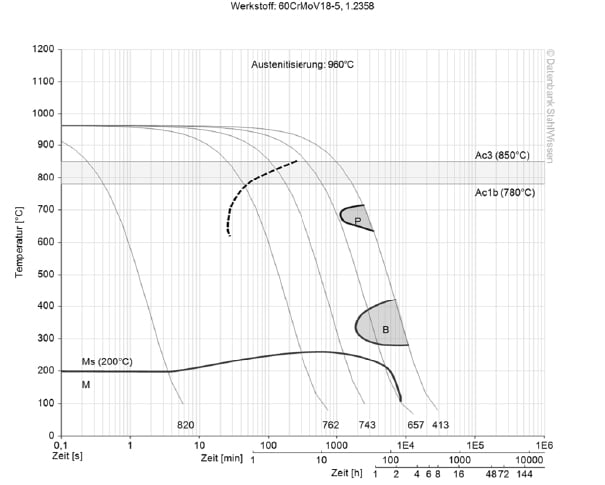

1.2358 Continuous TTT-Diagram

This diagram shows micro-changes over time at different temperatures. These are important in heat treatment because they provide information about the optimal conditions for processes such as hardening, annealing and normalising.

1.2358 Surface treatment

The choice of surface treatment depends on the requirements, the environment in which the workpieces/tools are used, the required properties and the expected loads.

To improve its performance and service life, the following surface treatments can be applied to 1.2358.

1.2358 Nitriding

During nitriding, nitrogen is diffused into the surface of the material to give it increased surface hardness, better wear resistance and corrosion resistance.

1.2358 Plasma nitriding

During plasma nitriding, nitrogen diffuses into the surface and forms nitrides. A more uniform glow discharge ensures consistent hardness even on complex workpieces. Plasma nitriding improves wear resistance, abrasion resistance, fatigue strength and resistance to friction welding.

Following plasma nitriding, the 1.2358 material can also be coated using the PVD or CVD process, as described below.

1.2358 Black oxide coating or blueing

Prior to oxidation, the material surface is thoroughly cleaned of deposits and adhesions and then immersed in an alkaline aqueous salt solution.

Black oxidation, also known as blue tinting, is a surface finishing process that reduces surface reflection and can increase corrosion resistance.

1.2358 PVD- and CVD coating

Both processes apply a thin layer to the surface of the material. This layer can increase surface hardness, wear resistance and corrosion resistance and improve lubricity.

- PVD – physical vapour deposition

- CVD – chemical vapour deposition

1.2358 Processing

1.2358 Electrical Discharge Machining (EDM)

EDM is used on workpieces that are manufactured from a single piece, for cutting shapes, or for producing complex and delicate shapes and sharp edges. The aforementioned shapes and edges can be achieved by selecting the right EDM process, the proper electrode and the correct parameters. The recast layer can be completely removed by grinding and polishing.

1.2358 Machining allowance / dimensional changes

Like most metals, this steel grade can contract and expand when heated or cooled. Phase changes, internal stresses and decarburisation can also cause dimensional changes that may affect the properties of this steel grade.

Controlled heating and cooling, stress relief and the prevention of overheating can reduce the risk of thermal shock and undesirable dimensional changes, such as warping or deformation, as well as cracking, which could mean that a project has to be started from scratch.

1.2358 Welding

Der 1.2358 kann mit den richtig gewählten Verfahren, Vorbereitung und Nachbehandlung geschweißt werden.

Before welding this material, ensure that the surface is free of contaminants such as grease, oil and rust. To minimise tension, the material should be preheated, the welding consumables should be similar to the base material and heat treatment should be carried out. After welding, the material should be checked for cracks and other defects to ensure that components can continue to be used safely after welding.