1.2360 / 1.2360 mod. - AT A GLANCE

What kind of steel is the 1.2360 / 1.2360 mod.?

1.2360 / 1.2360 mod., also known as Chipper Knife steel, an air hardening, 8% chromium, cold work tool steel.

This steel is suited for applications which need the combination of high toughness and good wear resistance. The X48CrMoV8-1-1 / X48CrMoV8-1 has an excellent dimensional stability during heat treatment.

Properties

All in all, 1.2360 / 1.2360 mod. is a very robust and universally applicable cold work tool steel. It is characterized by its through-hardenability, high toughness and wear resistance.

- Tool steel

- Chipper-Knife-Steel

- Cold work steel

- Air-hardenable steel

- High wear resistance

- Good tempering resistance

- Universally applicable

- Erodible

- Nitridable

- Not weldable

Applications

The 1.2360 / 1.2360 mod. often gets chosen for the combination of its wear resistance and toughness. Workpieces are exposed to forces like shock and impact as well as wear when e.g., chipping trees.

Here are a few applications of 1.2360 / 1.2360 mod.:

Punches, dies and moulding tools: Breakage and chipping when using 1.2360 / 1.2360 mod. is prevented due to its good wear resistance and excellent toughness. At room temperature, it can be easily shaped/formed, e.g. during cold stamping. The toughness of the 1.2360 / 1.2360 mod. prevents punches and dies from splitting or cracking and from deformation under pressure.

Knives, blades and cutting tools: Shear blades, slitting blades or cutting knives and blades need to have good cutting properties, but also be able to withstand some impacts. So the wear resistance and toughness of 1.2360 / 1.2360 mod. are also important here.

- Cutting tools

- Shear blades

- Slitter knives

- Blanking tools

- Stamping tools

- Embossing tools

- Forming dies

- Press dies

- Die inserts

- Extrusion dies

- Reinforcements

- Cold extrusion tools

- Tube tools

- Industrial knives

- Shearing blades for sheets up to 15 mm thick

- Industrial knives

- Wood chipping knives

- Veneer knives

1.2360 Standard values

Chemical composition:

| C | Si | Mn | P | S | Cr | Mo | V |

|---|---|---|---|---|---|---|---|

| 0.45 - 0.5 | 0.7 - 0.9 | 0.35 - 0.45 | 0.0 - 0.02 | 0.0 - 0.005 | 7.3 - 7.8 | 1.3 - 1.5 | 1.3 - 1.5 |

Chemical designation:

X48CrMoV8-1-1 / X48CrMoV8-1

Working hardness:

50-60 HRC

Delivery condition:

max. 250 HB

1.2360 / 1.2360 mod. Physical properties

What group of steel does the 1.2360 / 1.2360 mod. belong to?

- Tool steel

- Cold work steel

Is the 1.2360 / 1.2360 mod. a stainless steel?

Classic stainless steel has a mass fraction of at least 10.5% chromium, while 1.2360 / 1.2360 mod. has a mass fraction of 7.8%. Therefore, 1.2360 / 1.2360 mod. is not classic stainless steel. To protect 1.2360 / 1.2360 mod. and prevent corrosion, the parts ought to be coated with a protective layer.

Is the 1.2360 / 1.2360 mod. corrosion resistant?

Even though 1.2360 / 1.2360 mod. exhibits a certain degree of corrosion resistance due to its chromium content, it is not fully corrosion resistant. To be classified as corrosion-free steel, a steel grade must contain a minimum of 10.5% chromium.

Is the 1.2360 / 1.2360 mod. magnetisable?

In general, 1.2360 / 1.2360 mod. is a ferromagnetic steel and can therefore be magnetised and is suitable for use in the magnetic clamping technology.

1.2360 / 1.2360 mod. Cold work

The working temperature for the 1.2360 / 1.2360 mod. is in the range on 20 – 500 °C.

1.2360 / 1.2360 mod. Wear resistance

The steel composition of 1.2360 / 1.2360 mod. contains alloys such as chromium, molybdenum and vanadium, all of which increase the wear resistance of this steel. In addition to the alloys mentioned, 1.2360 / 1.2360 mod. has a high carbon content, which gives it a high degree of hardness.

1.2360 / 1.2360 mod. Technical properties

Is the 1.2360 / 1.2360 mod. a knife steel?

This steel grade, also known as chipper knife steel, can be used for wood chipper blades, for shredding wood and other fibrous materials, as the blades and knives have very good toughness and wear resistance. A knife or blade made of 1.2360 / 1.2360 mod. steel is not used for everyday use in the kitchen, but rather as an industrial and heavy-duty knife.

1.2360 / 1.2360 mod. Working hardness

The working hardness for 1.2360 / 1.2360 mod. is in the range of 50 – 60 HRC.

1.2360 / 1.2360 mod. Density

At room temperature, the density of 1.2360 / 1.2360 mod. is typically 7.8 g/cm3.

1.2360 / 1.2360 mod. Tensile strength

1.2360 / 1.2360 mod. has a tensile strength of approx. 850 N/mm² upon delivery. The tensile strength indicates the maximum load capacity. To obtain this information, a tensile test is carried out to show how much force is required to stretch or elongate a sample before it breaks.

1.2360 / 1.2360 mod. Yield strength

The yield point indicates how much stress can be exerted on a material before it undergoes plastic deformation. Before this point, it returns to its original shape as soon as the stress is removed from the material. Once this point is passed, it deforms permanently or even breaks.

1.2360 / 1.2360 mod. Machinability

On a scale where 1 is low and 6 is high the 1.2360 / 1.2360 mod. receives a 3 for its machinability.

1.2360 / 1.2360 mod. Heat conductivity

The following table shows the thermal conductivity of tool steel 1.2360 / 1.2360 mod. at different temperatures.

Heat conductivity

Value W/(m*K)

At a temperature of

26.1

20 °C

27.1

200 °C

28.6

400 °C

1.2360 / 1.2360 mod. Thermal expansion coefficient

The following table shows the expansion or contraction at different temperatures, which can be very important for work at high temperatures or when working with high temperature fluctuations.

Medium thermal expansion coefficient

Value W/(m*K)

At a temperature of

11.6

20 – 200 °C

11.3

68 – 400 °C

1.2360 / 1.2360 mod. Specific heat capacity

The specific heat capacity of 1.2360 / 1.2360 mod. is 0.460J/g-°C at room temperature. This value indicates how much heat is required to heat a certain amount of material by 1 Kelvin.

1.2360 / 1.2360 mod. Specific electrical resistance

The specific electrical resistance can be found in the following table. Electrical conductivity is the equivalent of specific electrical resistance.

Value (Ohm*mm²)/m

At a temperature of

0.19

20 °C

ORDER THE SMALLEST AMOUNT - WITHOUT A MINIMUM ORDER VALUE!

1.2360 / 1.2360 mod. Procedure

1.2360 / 1.2360 mod. Heat treatment

Heat treatment determines material properties. Therefore, it should always be carried out with care. Properties such as strength, toughness, surface hardness and temperature resistance are determined, which in turn can extend/improve the service life of parts, tools and components.

Heat treatment includes solution annealing, soft annealing, normalising, stress relief annealing, but also tempering, hardening and quenching or tempering.

1.2360 / 1.2360 mod. Annealing

After hot working and before re-hardening, the material should be annealed.

Heat the workpieces at a maximum rate of 220 °C per hour until a temperature of 885 °C is reached. Maintain this temperature for 1 hour per 25 mm thickness, but for at least 2 hours.

Finish the process by slowly cooling the material in the furnace in 10 °C increments per hour to 650 °C. Then continue cooling to room temperature in the furnace or in the air.

1.2360 / 1.2360 mod. Stress relieving

To relieve stress after rough machining, heat the workpiece to a temperature of 650°C and hold it there for 2 hours. Finish the process by slowly cooling it down in the furnace.

1.2360 / 1.2360 mod. Normalising

Normalising is generally a process for refining the microstructure of the material. The result of the finer microstructure is an improved grain structure and improved mechanical properties.

The normalising process is not carried out for this material quality.

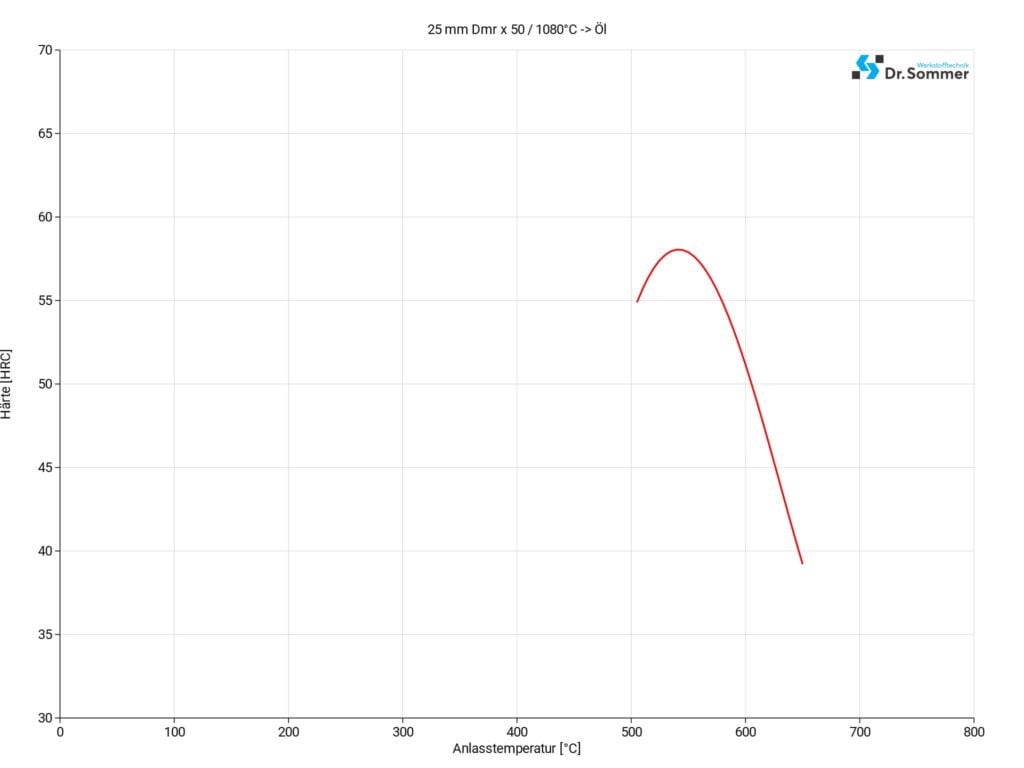

1.2360 / 1.2360 mod. Tempering

1.2360 / 1.2360 mod. Temper workpieces immediately after quenching in a temperature range of 150 – 315 °C. Hold for 1 hour per 25 mm thickness, but at least 2 hours, and allow to cool to room temperature in air. To temper workpieces twice, use a temperature of at least 480 °C.

For materials used for erosion or with a cross-section greater than 152 mm, a holding time of 4 to 6 hours is strongly recommended.

1.2360 / 1.2360 mod. Hardening

1.2360 / 1.2360 mod. preheat slowly. In the first step to 400 °C, then to 650 °C and continue to 850 °C. Continue with the austenitising temperature of 1030–1070 °C in a furnace or in salt and allow the workpiece to soak for 30 minutes for the first 25 mm thickness and 15 minutes for each additional 25 mm thickness.

1.2360 / 1.2360 mod. Sub-zero treatment

Sub-zero treatment can increase the wear resistance of 1.2360 / 1.2360 mod. and improve dimensional stability and toughness.

1.2360 / 1.2360 mod. Quenching

Size changes and/or distortions can be avoided by using the softest possible quenching medium. Quench immediately after hardening. When quenching in oil, ensure that the oil is preheated to a temperature of approx. 50–65 °C.

- Hot bath (workpiece cooled to approx. 550 °C)

- Air

- Compressed gas

- Quench in oil until it turns black at approx. 482 °C, then cool to 66 – 51 °C in still air.

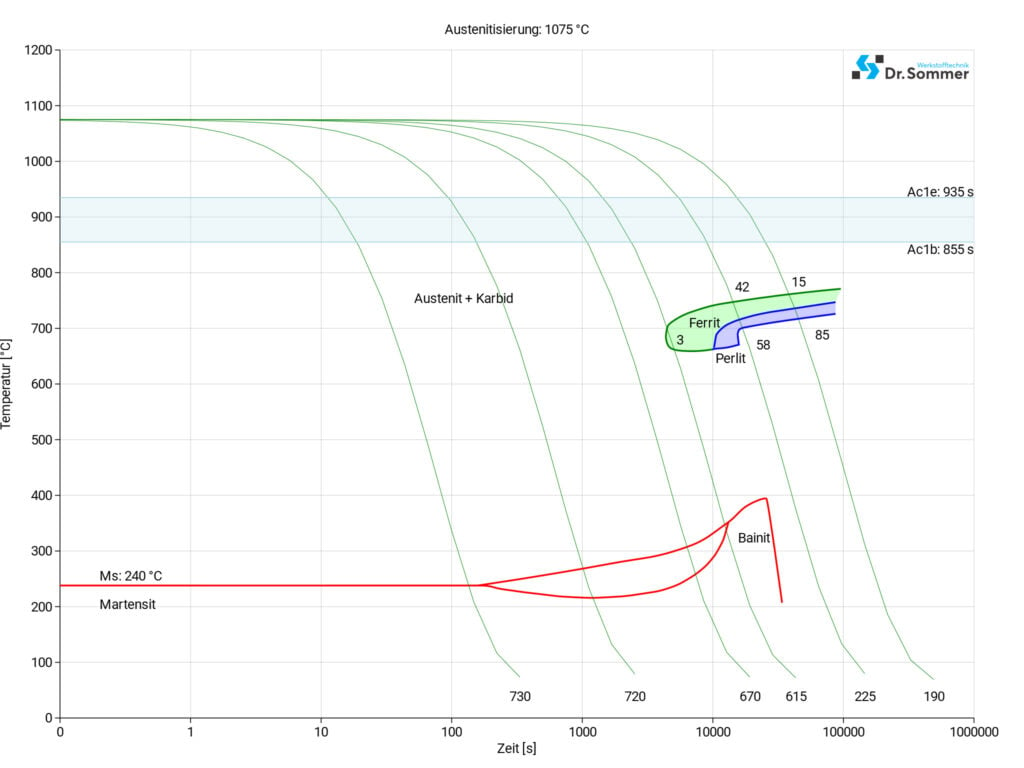

1.2360 / 1.2360 mod. Continuous TTT-Diagram

This diagram shows micro-changes over time at different temperatures. These are important in heat treatment, as they provide information about the optimal conditions for processes such as hardening, annealing and normalising.

1.2360 / 1.2360 mod. Surface treatment

1.2360 / 1.2360 mod. Nitriding

The introduction of nitrogen into the surface improves hardness and wear resistance and helps to extend the service life of the workpieces.

1.2360 / 1.2360 mod. Carburising

This process introduces additional carbon into the surface. Quenching and tempering the material after carburising hardens the surface layer while leaving the core tough

1.2360 / 1.2360 mod. Carbonitriding

Carbonitriding introduces carbon and nitrogen into the surface, which in turn gives the material a harder surface, better wear resistance and a longer service life for the workpieces.

1.2360 / 1.2360 mod. Black oxide coating or blueing

In most cases, this is a decorative finish. Coating the material with a black oxide layer also provides a certain degree of corrosion resistance.

1.2360 / 1.2360 mod. PVD and CVD coating

In both processes, the material is coated with a thin, hard layer. The process can increase hardness, improve wear resistance and reduce friction.

- PVD – physical vapour deposition

- CVD – chemical vapour deposition

1.2360 / 1.2360 mod. Processing

Care must be taken when machining 1.2360 / 1.2360 mod. As this is an air-hardening steel, the material should be removed quickly. Considerable heat can be generated during machining, which can cause the material to harden during processing.

1.2360 / 1.2360 mod. is a very hard material, which may require special tools for machining. Due to its high wear resistance, cutting tools may need to be changed or sharpened more frequently.

1.2360 / 1.2360 mod. Electrical Discharge Machining (EDM)

1.2360 / 1.2360 mod. can be eroded, even though the material can be extremely hard in some cases. As with other material grades, complex shapes can be eroded, and since there is no physical contact with the material, no mechanical forces are exerted on it. Erosion is a good choice for workpieces that require a tighter tolerance or a better surface finish. Erosion can leave a rough surface with a recast layer that can be removed by grinding and polishing, otherwise it can affect the service life and performance of the workpieces.

1.2360 / 1.2360 mod. machining allowance / dimensional changes

Heat treatments, machining or forging can lead to dimensional changes, but also to phase transformations during quenching. Severe heating can cause dimensional changes due to creep and decarburisation. As this is a cold work steel, care must be taken during heat treatment to avoid overheating. The correct quenching medium and quenching method should also be taken into account. To reduce internal stresses, it is recommended that the material be preheated and postheated.

1.2360 / 1.2360 mod. Forging

Heat the workpieces slowly to a temperature of 650 – 680 °C and then increase the temperature evenly to 1050 – 1100 °C. Forging should be carried out above a temperature of 1000 °C, but must never fall below 900 °C. The workpieces should be cooled slowly to avoid possible cracks.

1.2360 / 1.2360 mod. Welding

The 1.2360 / 1.2360 mod. is generally not suitable for welding.