1.2361 - AT A GLANCE

What kind of steel is the 1.2361?

Tool steel 1.2361 is a corrosion resistant martensitic chromium steel. It is hardenable and has a high chemical resistance, good polishability, good cutting edge retention as well as a long lasting sharpness. THe 1.2361 is corrosion resistant in mild environments, organic materials and mildly acidic environments as well as sweet water steam.

Properties

The 1.2361 offers a good balance between corrosion resistance, toughness, longevity and aesthetics. That makes it suitable for a wide variety of industries. Its service life, aesthetics and corrosion resistance can be increased through a variety of surface treatments. All of the above properties enable this steel grade to be used in a wide range of demanding environments.

- Tool steel

- Chromium steel

- Martensite

- Cold work steel

- High hardness

- High wear resistance

- Corrosion resistant

- Polishable to a high gloss finish

Applications

As a corrosion restistant,martensitic chromium steel the 1.2361 finds it uses in a variety of applications, as can be seen here.

- Cutting tools

- Knives

- Knife blades

- Cuttlery

- Guide rails

- Wear parts

- Perforated discs

- Screw elements

- Pump shafts

- Scale pans

- Horizontal cutting

- Surgical instruments

- Plastic moulds

- Injection nozzles

- Roller bearings

- Ball bearings

- Mechanical engineering

- Food industry

- Building industry

1.2361 Standard values

Chemical composition:

| C | Si | Mn | P | S | Cr | Mo | Ni | V | Cu |

|---|---|---|---|---|---|---|---|---|---|

| 0.86 - 0.96 | 0.0 - 1.0 | 0.0 - 1.0 | 0.0 - 0.045 | 0.0 - 0.03 | 17.0 - 19.0 | 0.9 - 1.3 | 0.0 - 0.3 | 0.07 - 0.12 | 0.0 - 0.3 |

Chemical designation:

X91CrMoV18

Working hardness:

53-58 HRC

Delivery condition:

max. 265 HB

1.2361 Physical Properties

What group of steel does the 1.2312 belong to?

- Martensitic tool steel

- Plastic mould steel

- Stainless steel corrosion resistant

- Stainless steel acid resistant

- Cold work steel

Is the 1.2361 a stainless steel?

Yes, with a mass fraction of 17 – 19 % of chromium the 1.2361 is a stainless steel.

Is the 1.2361 corrosion resistant?

Due to its chromium content of 17 – 19 % the 1.2361 is corrosion resistant.

1.2361 general corrosion rsistance

Steel grade 1.2361 is resistant aginst many petroleum products, organic materials, fresh water and steam. For the best corrosion resistance surfaces should be free of dust particles, lubricants, other coatings and residues. Work pieces should be cleaned and/or passivated after manufacturing.

Is the 1.2361 magnetisable?

Yes, the 1.2361 belongs to the maagnetisable stainless stees group. When used on machines with magnetic adhesion, it can be ground, milled or eroded, for example.

1.2361 Wear resistance

The 1.2361 receives a 5 on a scale where 1 is low and 6 is high.

1.2361 Technical properties

Is the 1.2361 a knife steel?

With a lower carbon content than other stainless steels the 1.2361 can be sharpend easily but does not retain its edge well enough. However, it still offers a good balance between toughness, corrosion resistance and edge retention. Its corrosion resistance in wet and acidic environments makes it suitable for the manufacture of kitchen and immersion knives.

1.2361 Working hardness

The working hardness for this steel grade is at approx. 53 – 58 HRC.

1.2361 Density

Typically the density of the 1.2361 at room temperature is at 7,7 g/cm3.

1.2361 Tensile strength

The tensile strength of tool steel 1.2361 is at approx. 900 N/mm2. To obtain these findings, a tensile test is carried out to show how much force is required to stretch or elongate a sample before it breaks.

1.2361 Machinability

Tool steel 1.2361 receives a 2 for its machinability on a scale where 1 is low and 6 is high.

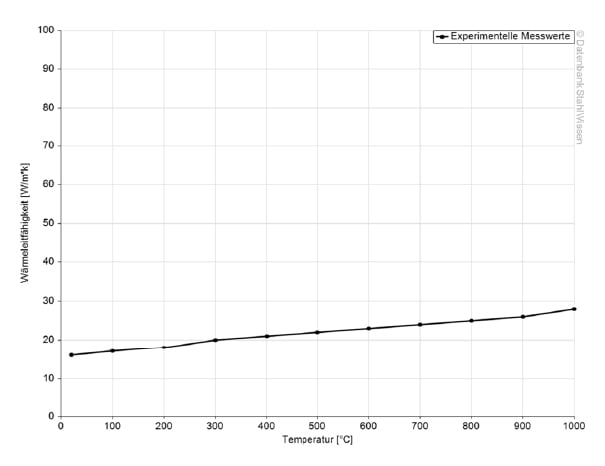

1.2361 Heat conductivity

1.2361 Thermal expansion coefficient

This diagram shows how much the 1.2361 can expand or contract when temperatures change. This can be very important when working with high temperatures or significant temperature fluctuations.

Medium thermal expansion coefficient

Value 10-6m/(m*K)

At a temperature of

10.5

20 – 100 °C

11.0

20 – 200 °C

11.0

20 – 300 °C

12.0

20 – 400 °C

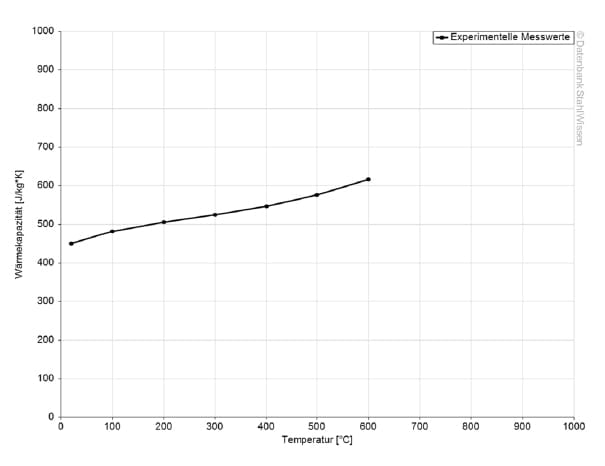

1.2361 Specific heat capacity

The specific heat capacity of 1.2361 at room temperature is 0.46 J/g*K. This value indicates how much heat is required to heat a certain amount of material by 1 Kelvin.

1.2361 Specific electrical resistance

The temperature-dependent material constant (specific resistance) can be found in the following table. Electrical conductivity is the reciprocal of specific resistance.

Specific electrical resistivity

Value (Ohm*mm²)/m

Bei einer Temperatur von

0.65

20 °C

FASTEST POSSIBLE DELIVERY!

1.2361 Procedure

1.2361 Heat treatment

Heat treatment is used to determine material properties. It should therefore always be carried out with care. Properties such as strength, toughness, surface hardness and temperature resistance are determined, which in turn can extend/improve the service life of parts, tools and components.

Heat treatment includes solution annealing, soft annealing, normalising, stress relief annealing, but also tempering, hardening and quenching or tempering.

1.2361 Annealing

Heat the steel grade 1.2361 evenly to a temperature of 800 – 850 °C and hold for annealing. After the work pieces are cooled down slowly in the furnace.

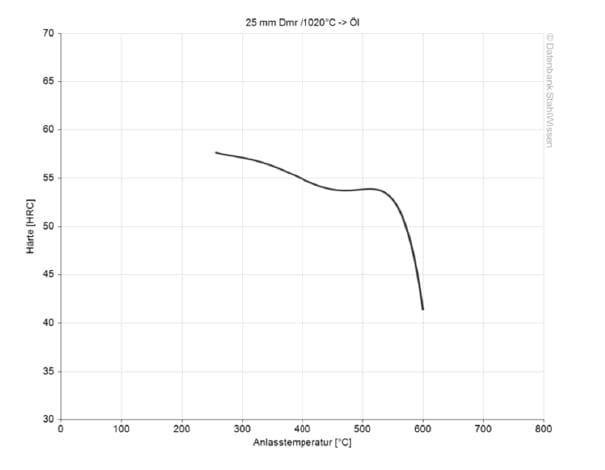

1.2361 Tempering

Tempering the 1.2361 can release residual stresses as well as getting the balance between strength and toughness.

You are able to find more information in the graph below:

1.2361 Hardening

To harden the 1.2361 heat it evenly to a temperature of 1000 – 1050 °C and hold it. Then quench the material.

1.2361 Quenching

The material grade 1.2361 can be quenched in the following media.

- Oil

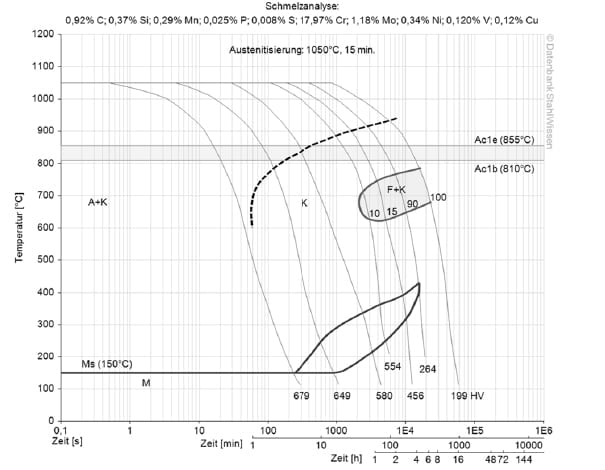

1.2361 Continuous TTT-Diagram

The TTT-diagram usually shows micro-changes over time at different temperature. These are important in heat treatment as they provide information on the optimal conditions for processes such as hardening, annealing and normalising.

1.2361 Surface treatment

Treating the surface of the 1.2361 has some advantages like a longer service life, improved performance, corrosion resistance or visual appeal of work pieces made from this steel grade.

Following you are able to find some examples of surface treatments suitable for the 1.2361.

1.2361 Nitriding

Nitriding diffuses nitrogen into the surface of this steel which in turn gives it a harder and more wear resistant surface. It can improve the service lief as well as the corrosion resistance.

1.2361 Passivation

This process removes free iron from the surface of the material and can inhance its natural corrosion resistance.

1.2361 Black oxide coating or blueing

Blueing is usually carried out for aesthetic reasons. It gives the workpieces a blue-black colour, which reduces light reflection on the surface.

1.2361 PVD and CVD coating

Both processes, PVD and CVD coating, apply a thin layer to the surface of the material. This thin, hard layer gives the material a wear-resistant coating.

- PVD – physical vapour deposition

- CVD – chemical vapour deposition

1.2361 Shot peening

During this process, multiple high-speed shots are fired at the surface of the material, leaving small indentations to eliminate stress peaks. This makes the surface more resistant and can prevent fatigue and stress corrosion damage.

1.2361 Grinding and polishing

For some applications, grinding and polishing are very important steps. A high-quality surface contributes to corrosion resistance in applications such as cutlery. However, care should be taken not to overheat the workpieces, as this can reduce corrosion resistance.

1.2361 Processing

1.2361 Electrical Discharge Machining (EDM)

Erodieren wird häufig für schwer zu bearbeitende Stähle und präzise Abmessungen oder Formen eingesetzt, die bei herkömmlichen Bearbeitungsmethoden eine Herausforderung darstellen.

Wärmebeeinflusste Zonen benötigen möglicherweise nach dem Erodieren eine weitere Wärmebehandlung, um die Mikrostruktur im Werkstück wieder herzustellen. Nach dem Erodieren sollte die Recast-Schicht, eine dünne weiße Schicht, entfernt werden.

1.2361 Machining allowance / dimensional changes

Dimensional changes can result from various situations. Heating, cooling, phase changes or stress relief can all result in dimensional changes.

Controlled heating and cooling, stress relieving or by using devices which can minimise or avoid the expansion or contraction during the heat treatment can help control dimensional changes.

1.2361 Forging

Heat the material slowly and evenly to a temperature of 1180 °C and make sure not to overheat it as this may result in loss of ductility and toughness. Forging should not be continued under a temperature of 1010 °C. Heat the material when needed anew. When finished forging the material should be cooled slowly in the furnace and then annealed immediately afterwards. Cooling in air should be avoided as this may result in cracking.

1.2361 Welding

1.2361 is not normally recommended for welding as it hardens in air and has high hardenability. If it is necessary to weld this material, similar consumables should be used to maintain the mechanical properties. Preheat the workpiece to a temperature of 260 °C and do not allow it to fall below this temperature at any time. Immediately after welding, the workpieces should be annealed for 6 – 8 hours at 732 – 760 °C. Do not allow the temperature to fall below 260 °C between welding the workpiece and annealing. After annealing, the workpiece should be cooled slowly in the furnace to prevent cracking.