1.2363 - AT A GLANCE

What kind of steel is the 1.2363?

A2 is an air hardening, cold work steel. The combination of high wear resistance and good toughness makes the A2 suitable for a wide variety of applications.

Tool steel 1.2363 (X100CrMoV5-1) with a mass fraction of 5% chromium has an excellent combination of wear and chipping resistance as well as excellent machining and grinding properties.

Properties

A2 tool steel is a reliable choice as it has a good balance between wear resistance and toughness. As it has good dimensional stability during heat treatment, this material is often used for tools. Care should be taken during heat treatment to maintain the best performance of the material and prevent deformation. With proper care, this material can have a long life.

Practically, this means:

- Air-hardenable cold work steel

- Good machinability

- High wear resistance

- Improved toughness

- Low dimensional change

- Repair weldable

- Nitridable

- Erodible

- Working hardness between 58 and 62 HRC

- Very good dimensional stability

- High compressive strength

- 1.2363 is nitridable which is not a common practise

- similar to the 1.2379 or 1.2842

Applications

Steel properties like wear resistance and chipping resistance make the 1.2363 a good fit for applications requiring extreme accuracy of size, as well as for very large parts like:

- Cutting tools

- Trimming tools

- Coining dies

- Wear inserts

- Precision tools

- Blanking tools

- Stamping tools

- Dies

- Punches

- Thread rolling tools

- Thread rolling dies

- Shear knives

- Circular shear knives

- Cold pilger mandrels

- Cold stamping tools

- Plastic molds

1.2363 Standard values

Chemical composition:

| C | Si | Mn | P | S | Cr | Mo | V |

|---|---|---|---|---|---|---|---|

| 0.95 - 1.05 | 0.1 - 0.4 | 0.4 - 0.8 | 0.0 - .03 | 0.0 - 0.03 | 4.8 - 5.5 | 0.9 - 1.2 | 0.15 - 0.35 |

Chemical designation:

X100CrMoV5-1

Working hardness:

58-62 HRC

Delivery condition:

max. 241 HB

1.2363 Physical properties

What group of steel does the 1.2363 belong to?

- Tool steel

- Cold work steel

- Plastic mould steel

Is the 1.2363 corrosion resistant?

The 1.2363 has a certain corrosion resistance but not like a typical stainless steel. A classic stainless steel has a mass fraction of at least 10,5 % chromium while the 1.2363 has a mass fraction of 4,8 to 5,5 % chromium. When corrosion resistance is an important propety needed for your projekt stainless steel should be considered.

Is the 1.2363 magnetisable?

Like other steels the 1.2363 contains iron and is ferromagnetic, this means it can be magnetised. This makes it possible to use magnetic clamping for machining this material grade.

1.2363 Cold work

The 1.2363 is an air hardener that can be cold worked. Care should be taken as it can come to inner stresses which can result in cracks and deformation. Cold forming can cause material 1.2363 to become brittle or even crack, which can affect its formability. Cold forming of 1.2363, which has good toughness and wear resistance, has the advantage of offering better dimensional tolerances than hot forming.

1.2363 Wear resistance

The wear resistance of the 1.2363 receives a 4 on a scale where 1 is low and 6 is high.

1.2363 Technical Properties

Is the 1.2363 a knife steel?

Although 1.2363 tool steel can be used as knife or blade steel due to its combination of wear resistance, toughness, edge retention and ease of sharpening, it is mainly used for tactical knives or hunting knives. Although it has some corrosion resistance, 1.2363 is not a stainless steel, and knives made from this steel should be maintained regularly and protected from humid environments to prevent corrosion.

1.2363 Working hardness

The working hardness for the 1.2363 is between 58 and 62 HRC.

1.2363 Density

For tool steel 1.2363 the typical density at room temperature is at 7,86 g/cm3.

1.2363 Machinability

On a sclae where 1 is low and 6 is high the 1.2363 receives a 3 for its machinability.

1.2363 Tensile strength

The 1.2363has a tensile strength of approx. 815 N/mm2 at delivery. The tensile strength indicates the maximum load capacity. To obtain this information, a tensile test is carried out to show how much force is required to stretch or elongate a sample before it breaks.

1.2363 Yield strength

The yield strength for the 1.2363 is at approx. 1.270 – 2.200 N/mm2. The yield strength indicates how much stress can be applied before a material undergoes plastic deformation. Beyond this point, the material no longer returns to its original shape when the stress is removed, but remains deformed or even breaks.

1.2363 Heat conductivity

The following table shows the heat conductivity of tool steel 1.2363 at different temperatures.

Heat conductivity

Value (W/m*K)

At a temperature of

15.8

20 °C

26.7

350 °C

29.1

700 °C

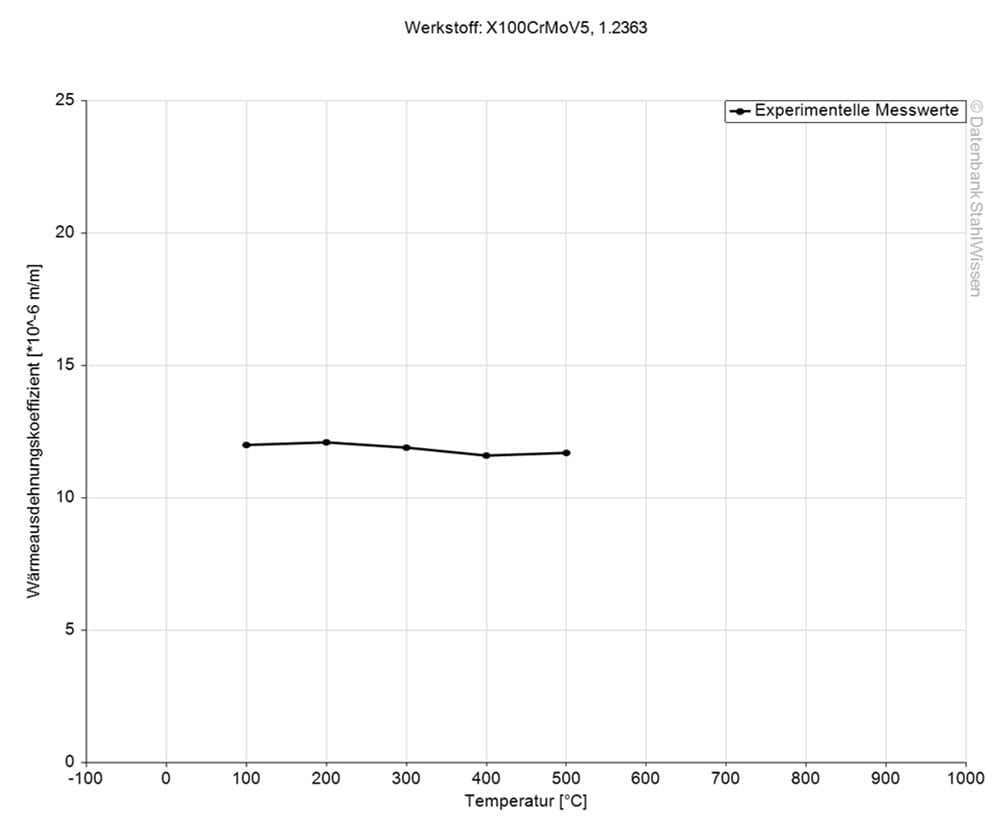

1.2363 Thermal expansion coefficient

This diagram shows how much the 1.2363 can expand or contract when temperatures change. This can be very important when working with high temperatures or significant temperature fluctuations.

1.2363 Specific heat capacity

The specific heat capacity of 1.2363 at room temperature is 0.46 J/g*K. This value indicates how much heat is required to heat a certain amount of material by 1 Kelvin.

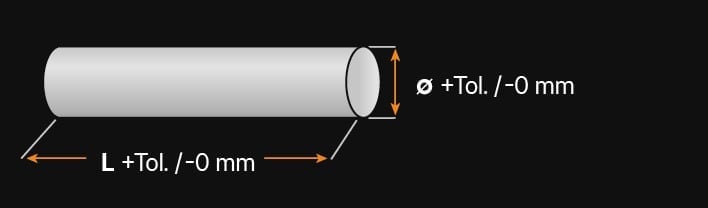

PRECISION ROUND STEEL WITH MACHINING ALLOWANCE – PEELED / ROUGH TURNED!

1.2363 Procedure

1.2363 Heat treatment

Care should be taken when heat treating 1.2363 to prevent decarburisation.

1.2363 Annealing

Tool steel 1.2363 should be protected and heated evenly to a temperature of 800 – 840 °C. The cooling process should be done in the furnace at approx. 10 °C per hour to a temperature of 650 °C and then the work pieces can cool further down in air.

1.2363 Stress relieving

To reduce residual stresses after machining heat the material to a temperature of 650 °C and hold for 2 hours. Afterwards let the material cool down to a temperature of 500 °C in the furnace and the cooling down further can be done in air.

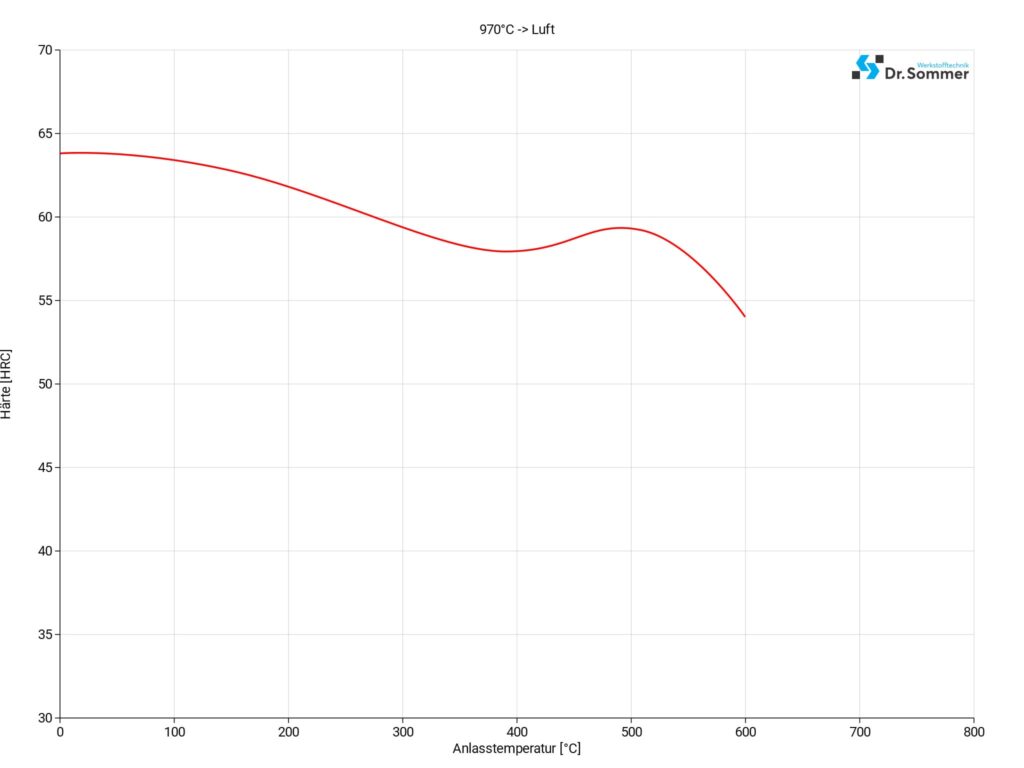

1.2363 Tempering

As soon as the parts reach a temperature og 65 °C after quenching they should be tempered. The usual tempering temperature for the 1.2363 is in a range of 150 – 260 °C.

For tools that have to withstand high impacts a double tempering procedure should be done in a temperature range of 480 – 540 °C. For smaller pieces the tempering temperature should be held for a minimum of 1 hour and for lager pieces 1 hour per 25 mm thickness.

More information can be obtained in the following diagram:

1.2363 Hardening

The 1.2363 should be pre heatedto a temperature of 650 – 750 °C after reaching that temperatur it should be quickly taken to a temperature of 930 – 970°C and hold for 30 minutes that the material can heat trough evenly. Following the material is coold down to room temperature in dry, mild air. To prevent decarburisation and oxidation, the workpieces should be protected during heat treatment.

1.2363 Tiefkühlbehandlung

For maximum dimentioanl stability work pieces can be treated in sub-zero temperatures and/or artificially aged.

Immediately after quenching the work pieces should be treated at sub-zero temperatures of -40 to -80 °C and held for 2 to 3 hours. The sub-zero treatment can increase the hardness by 1 -3 HRC. More complex forms should not be treated in sub-zero temperatures as they can crack.

1.2363 Artificially ageing

When artificially ageing steel, tempering after quenching is replaced by heating to 110–140 °C for a holding time of 25–100 hours.

1.2363 Quenching

Quenching should be carried out as quickly as possible. To avoid excessive deformation and/or quenching cracks, cooling should be uniform and at a sufficient cooling rate.

- Oil for small and simple workpieces

- Vacuum furnace with gas overpressure during cooling

- Convection or atmosphere

- Martempering bath or fluidised bed at 180–220 °C or 500–550 °C with subsequent cooling in air.

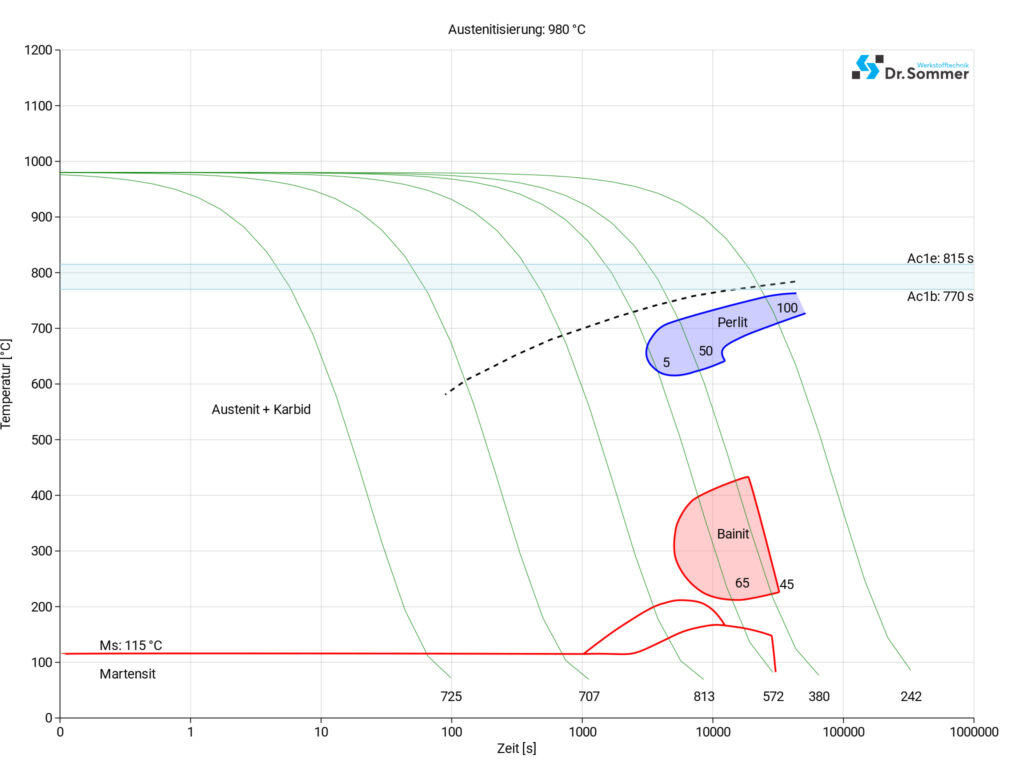

1.2363 Continuous TTT-Diagram

The TTT-diagram usually shows micro-changes over time at different temperature. These are important in heat treatment as they provide information on the optimal conditions for processes such as hardening, annealing and normalising.

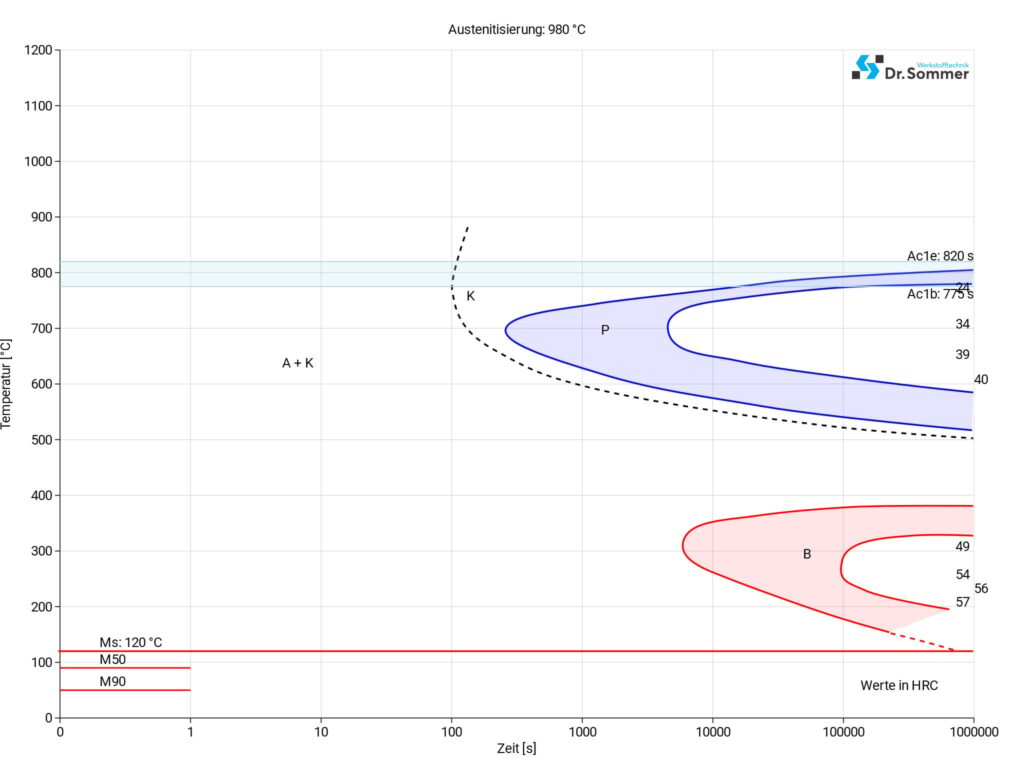

1.2363 Isothermal TTT-diagram

This diagram shows the structural changes at micro level over time at a constant temperatur. It shows at which temperatures after what time the different phases like perlit, martensite or bainite start to form.

1.2363 Surface treatment

To reduce friction and increase wear and corrosion resistance, some cold work steels are surface treated by nitriding, titanium nitriding or hard chrome plating.

1.2363 Nitriding

Nitriding gives the surface of the material a hard layer with excellent resistance to wear and abrasion. The thickness of the nitriding layer should be carefully considered to suit the specific application.

1.2363 Processing

1.2363 Electrical Discharge Machining (EDM)

When eroding in a hardened and tempered state, the recast layer can be completely removed by grinding and polishing, for example. Then allow the tool to cool to approx. 25 °C below the previous tempering temperature and hold it at this temperature for 2 hours.

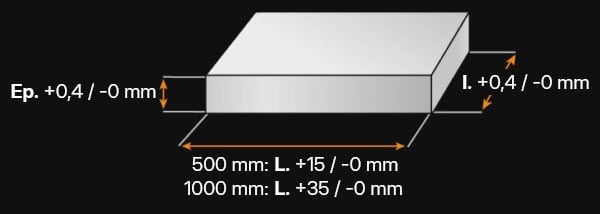

1.2363 Machining allowance / dimensional changes

1.2363, like other tool steels, retains its size best when quenched at the correct hardening temperature. 1.2363 shrinks after tempering if it is overheated and should therefore not be hardened at temperatures above 970°C. In contrast, it expands when tempered below 315°C.

1.2363 Forging

Heat the workpieces evenly to a temperature range of 1065 – 1120 °C and avoid forging below a temperature of 927 °C. The material should be reheated as often as necessary. To cool larger parts, heat the furnace to approximately 840 °C, place the workpiece in the furnace and maintain this temperature until the parts are evenly heated through. Then switch off the furnace and allow the workpieces to cool slowly in the furnace. Please note that this is not annealing; the workpieces should be annealed as described in section ‘1.2363 Annealing’ after they have been forged and cooled.

1.2363 Welding

Good results can be achieved when welding tool steel if the appropriate precautions are taken (increased working temperature, seam preparation, selection of the right filler materials and welding process). If the parts are to be polished or photo-etched, it is necessary to use a suitable type of electrode.