1.2365 - AT A GLANCE

What kind of steel is the 1.2365?

The thermal conductivity, which makes the 1.2365 steel grade unresponsive to temperature changes and the ability to be water cooled, make 1.2365 an excellent choice for high-speed forging dies or for tools which are exposed to high thermal strains.

1.2365 offers high toughness and can be used very well for cold forming. The former mentioned characteristics make this tool steel the best choice for a lot of applications in a good variety of industries.

Properties

1.2365 tool steel is often used where properties such as high temperature strength, hardness and minimal distortion during the hardening process are important.

Practically, this means:

- High toughness

- Very good for cold forming

- High hardness has a positive effect on wear resistance

- High hardness can pose a challenge during machining

- Working hardness is in the range of 50 – 52 HRC

- Hot work steel

- For the automotive industry

- For metal processing and manufacturing

- For mechanical engineering

The 1.2365 can be used for many different applications like cutting tools, dies or hot work tools and hot work dies.

Applications

1.2365 can be used in a wide variety of applications, for example:

- Extrusion presses

- Brass casting

- Press tools

- Die inserts

- Die casting molds

- Plastic molds

- Recipient bushes

- Pressure dies

- Press mandrels

- Tube extrusion mandrels

- Piecer plugs

- Press dies

- Block receivers

- Screw production

- Nut production

- Rivet production

- Bolts production

- Hot shear knives

1.2365 Standard values

Chemical composition:

| C | Si | Mn | P | S | Cr | Mo | V |

|---|---|---|---|---|---|---|---|

| 0.28 - 0.35 | 0.1 - 0.4 | 0.15 - 0.45 | 0.0 - 0.03 | 0.0 - 0.02 | 2.7 - 3.2 | 2.5 - 3.0 | 0.4 - 0.7 |

Chemical composition:

32CrMoV12-28

Working hardness:

50-52 HRC

Delivery condition:

max. 229 HB

1.2365 Physical Properties

What group of steel does the 1.2365 belong to?

- Tool steel

- Plastic mould steel

- Hot work steel

Is the 1.2365 a stainless steel?

The tool steel 1.2365 is not a stainless steel. To be classified as stainless steel a steel has to have a chromium content of at least 10.5 %.

Is the 1.2365 corrosion resistant?

With a mass fraction of 2.7 – 3.2 % of chromium lends this steel grade a certain corrosion resistance but this is not enough to prevent staining or corrosion in corrosive environments.

Is the 1.2365 magnetisable?

As a ferrous metal, 1.2365 can be magnetised. Grinding, milling and eroding can be carried out on machines with magnetic adhesion, for example.

1.2365 Hot work

1.2365 has good thermal toughness, high hot hardness and is resistant to thermal cracking. This makes 1.2365 a good choice, for example, for forging, hot punching or hot shearing knives.

1.2365 Wear resistance

On a scale where 1 is low and 6 is high the 1.2365 receives a 5 for its wear resistance.

1.2365 Technical Properties

Is the 1.2365 a knife steel?

The 1.2365 is not the ideal choice for knife making as it does not have the needed toughness or corrosion resistance for a knife. Its high hardness make it possible for a good cutting edge but when it comes to re-sharpening it can be challenging.

1.2365 Working hardness

The working hardenss for the 1.2365 is approx. 50 – 52 HRC.

1.2365 Density

Typically the density for tool steel 1.2365 at room temperature is 7,78 g/cm3.

1.2365 Machinability

On a scale where 1 is low and 6 is high the 1.2365 gets a 5 for its machinability.

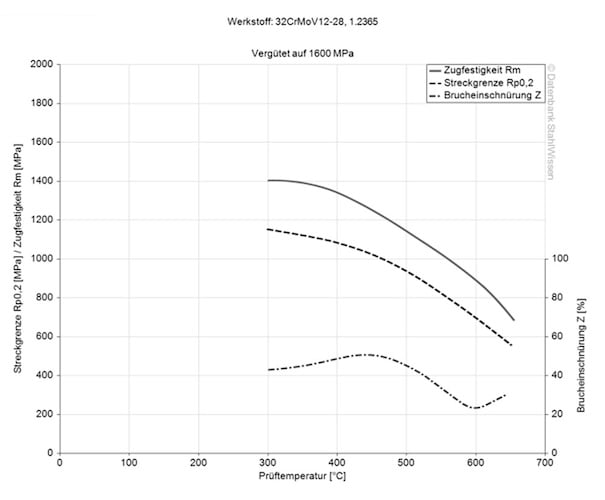

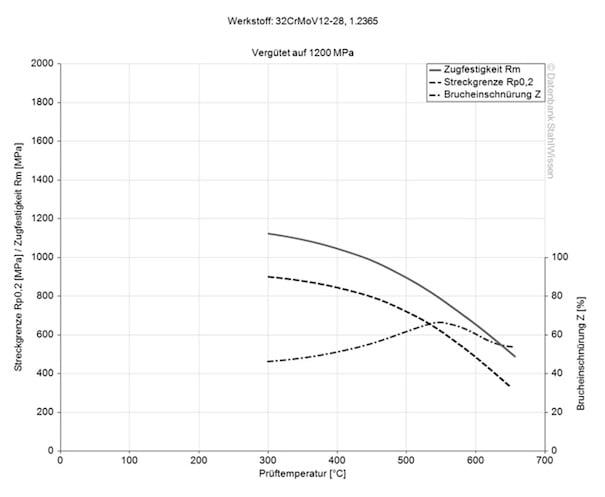

1.2365 Tensile strength

The tensile strength of tool steel 1.2365 is approx. 770 N/mm2. This value is the result of a tensile test that shows how much force is required to cause the material to stretch or deform before it breaks.

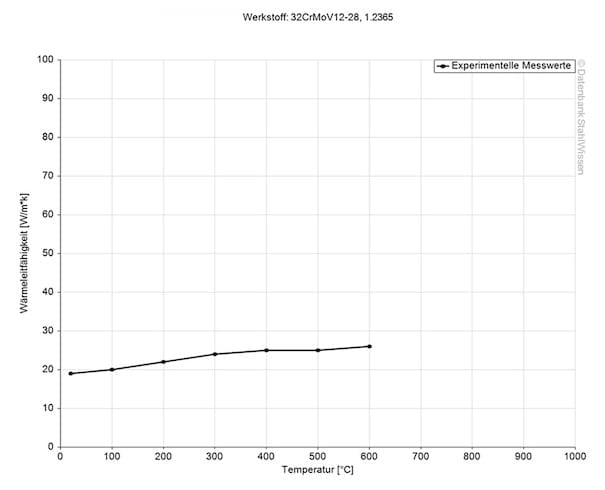

1.2365 Heat conductivity

The following table shows the heat conductivity for tool steel 1.2365 at various temperatures.

Heat conductivity

Value (anneled)

Value (tempered)

At a temperature of

32.8

31.4

20 °C

34.5

32.0

350 °C

32.2

29.3

700 °C

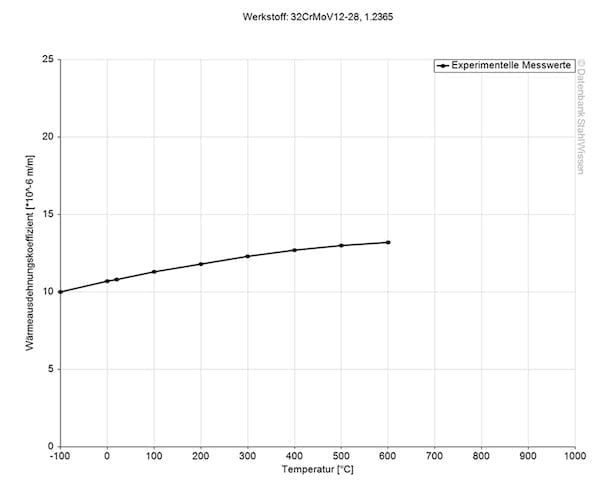

1.2365 Thermal expansion coefficient

The thermal expansion coefficient shows how much a material expands or contracts at temperature changes. This information can very important when working with high temperatures or during applications with stark temperature changes during an application.

Medium thermal expansion coefficient

Value 10-6m/(m*K)

At a temperautre of

11.8

20 – 100 °C

12.5

20 – 200 °C

12.7

20 – 300 °C

13.1

20 – 400 °C

13.5

20 – 500 °C

13.6

20 – 600 °C

13.8

20 – 700 °C

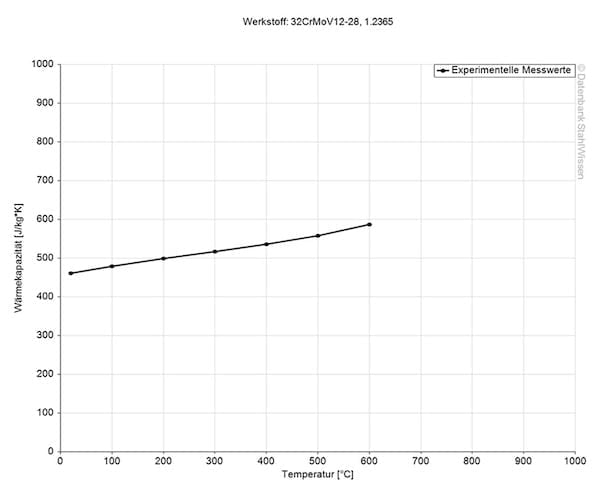

1.2365 Specific heat capacity

The specific heat capacity of tool steel 1.2367 at room temperature is 0.46 J/g*K. This value indicates how much heat is required to heat a specific amount of material by 1 Kelvin.

1.2365 Specific electrical resistance

The specific electrical resistance can be found in the following table. Electrical conductivity is the reciprocal of specific electrical resistance.

Specific electrical resistance

Value (Ohm*mm2)/m

At a temperature of

3.37

20 °C

PRECISION!

1.2365 Procedure

1.2365 Heat treatment

The heat treatment is used to determine material properties. It should therefore always be carried out with care. Properties such as strength, toughness, surface hardness and temperature resistance are determined, which in turn can extend/improve the service life of parts, tools and components.Heat treatment includes solution annealing, soft annealing, normalising, stress relief annealing, but also tempering, hardening and quenching or tempering.

Heat treatment includes solution heat treatment, soft annealing, normalising, stress-relief heat treatment, but also tempering, hardening and quenching.

1.2365 Annealing

Heat the workpieces evenly to a temperature of 750–800 °C, maintain this temperature for 6–8 hours, then cool them slowly in the furnace at a rate of 10–20 °C per hour to a temperature of 600 °C. Complete this process by allowing the pieces to cool further in the air. Precautions should be taken to avoid excessive decarburisation/carburisation.

1.2365 Stress relieving

After initial processing, 1.2365 should be heated evenly to a temperature of 600–650 °C. Then hold in a neutral atmosphere for 2–6 hours, depending on the size of the workpieces, and allow to cool slowly in the furnace.

1.2365 Tempering

Directly after hardening the workpieces they should be tempered. Allow 2 hours for smaller pieces and for larger pieces allow 1 hour per 20 mm thickness at a temperature of 450 – 570 °C. For better toughness it is recommended to repeat the tempering process a second tim and, a third time to relax the workpiece at approx. 50 °C below the highest tempering temperature.

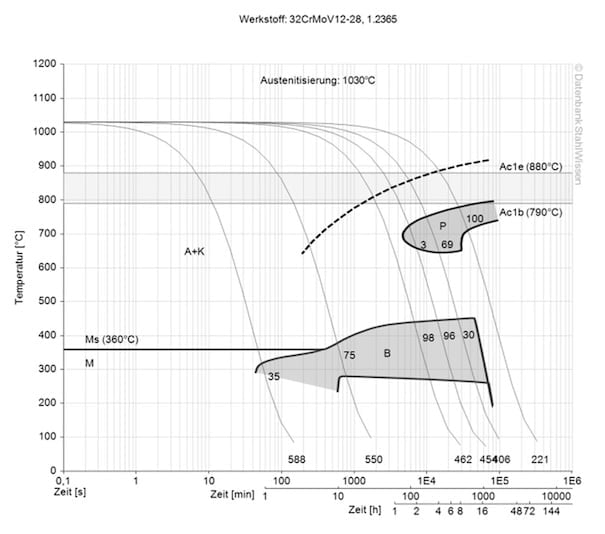

1.2365 Hardening

Heat material grade 1.2365 evenly to a temperature of 1030 – 1050 °C and hold it at that temperature for 15 to 30 minutes. For maximum hardness quench the material in oil. For most applications this material can be cooled down in air. To minimise decarburisation it should be cooled in a salt bath or controlled environment.

1.2365 Quenching

To avoid excessive deformation and/or quenching cracks cooling should be even and at a sufficient cooling rate.

- Air

- Oil

- In an oven with a controlled environment

- Salt bath, after the material has been evenly heated it is held for 15 – 30 minutes at a temperature of 500 – 550 °C.

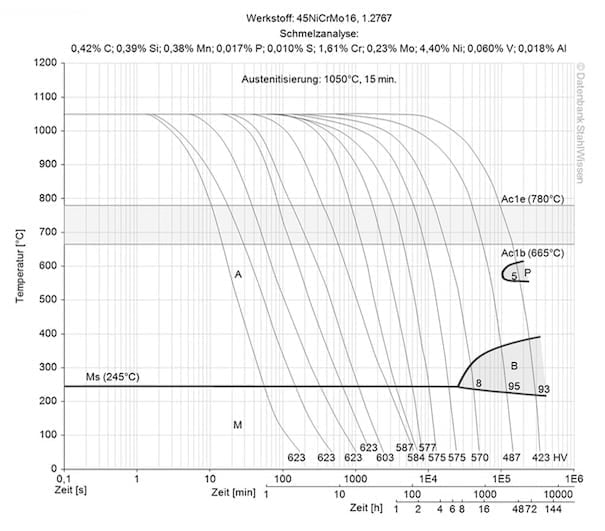

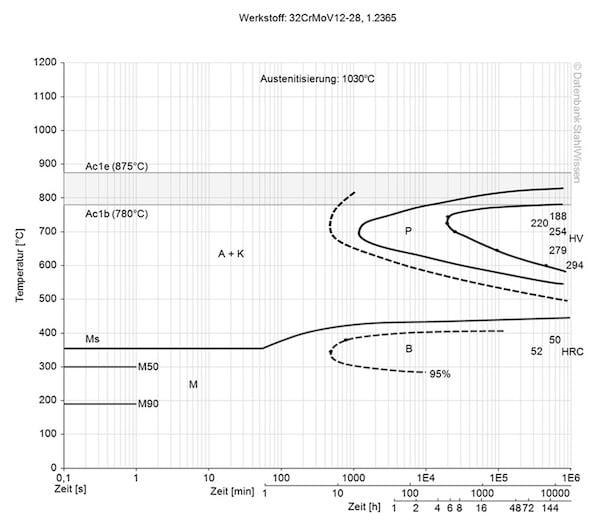

1.2365 Continuous TTT-diagram

This diagram shows micro-changes over time at different temperatures. These are important in heat treatment because they provide information about the optimal conditions for processes such as hardening, annealing and normalising.

1.2365 Isothermal TTT-diagram

This diagram shows the structural changes at the micro level over time at a constant temperature. It shows at what temperature and after what time different phases, e.g. perlite, martensite or bainite, begin to form.

1.2365 Surface treatment

A surface treatment can enhance the wear and corrosion resistance and gives workpieces a higher surface hardness. Below are a few examples of possible surface treatments.

1.2365 Nitriding

During the nitriding process nitrogene is introduced into the surface of the 1.2365. This gives workpieces a higher wear resistance, harder surface and longer service life.

1.2365 Carburising

To give the 1.2365 a better surface hardenss and wear resistance it can be carburised. During that process carbon is introduced into the surface of the workpiece.

1.2365 PVD and CVD

PVD (Physical Vapor Deposition) as well as CVD (Chemical Vapor Deposition) overlay the material with a very thin protective layer from for example TiN (titanium nitride). This protective layer improves wear resistance and reduces friction.

1.2365 Chrome plating

A thin chrome layer is applied to the surface to increase the corrosion resistance and to reduce friction.

1.2365 Processing

1.2365 Dimensional changes

Like all metals, tool steel 1.2365 expands when heated and contracts when cooled. To prevent stress and deformation, heating the material evenly can prevent or minimise dimensional changes. Dimensional changes can occur during phase changes, due to improper quenching, internal stresses and decarburisation. It is important to use the correct temperatures, relieve stress and quench the material correctly to minimise the possibility of deformation.

1.2365 Forging

The material should be heated slowly and evenly to a temperature range of 1040–1090 °C. Reheat as often as necessary and do not allow the temperature to fall below 900 °C. At the end of the process, allow to cool slowly in lime, dry ash or in the furnace, and always anneal the workpieces after forging.