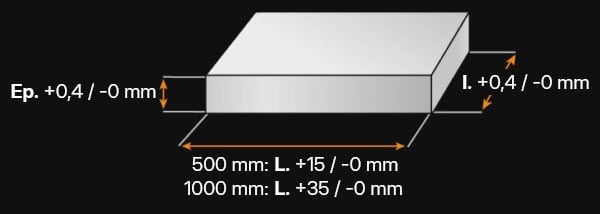

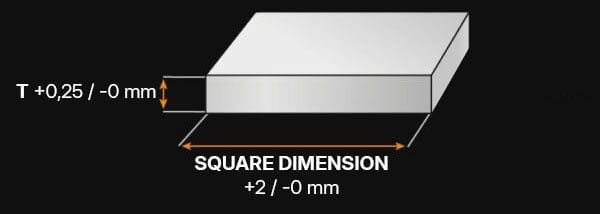

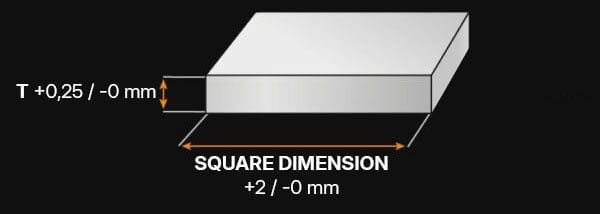

EDM Block / Erosion Block - annealed [EDM]

Square dimension milled / ground - Grain structure is vertically directed in relation to base surface

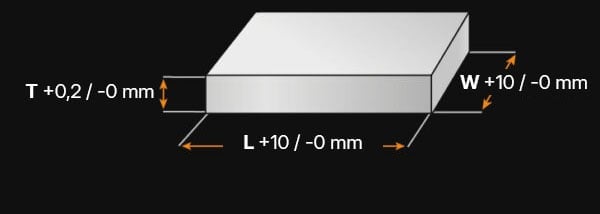

EDM Block / Erosion Block - hardened [EDM]

Square dimension milled / ground - Grain structure is vertically directed in relation to base surface

Would you like to find out more about the 1.2379 and its benefits?

1.2379 - AT A GLANCE

What kind of steel is the 1.2379?

D2 Steel is a high carbon- and chromium steel with added alloys like molybdenum and vanadium. It is a high alloy, secondary-hardening, ledeburitic cold work steel. This high chromium steel is known for its low distortion and wear resistance and can also be found under the discription X153CrMoV12.

Properties

This Tool Steel and Plastic Mold Steel is often used when high wear resistance, tempering resistance and good ductility is needed. As well as the forementioned properties this steel presents high compression strength, good through-hardenability, high stability during hardening as well as an excellent cutting-edge retention.

- It is low-distortion

- It is wear-resistant

- It is through-hardenable

- It is pressure-resistant

- It is temper resistant

- It can be nitrided and eroded

- It is dimensionally stable

- PVD and CVD surface treatments is possible

- Black oxidizing the material is not possible

- Working hardness is a maximum of 62 HRC

Applications

1.2379 Tool Steel is a high-performance steel, often used for its hardness and wear resistance in many different areas, e.g., in several industrial sectors.

Here are a few examples:

- 1.2379 cutting and punching tools: Due to the high wear resistance and hardness, this steel is often used to manufacture punching and cutting tools (up to 25,5 mm). These include industrial knives, shears or cutting plates as well precision cutting tools up to 12 mm thickness.

- 1.2379 blanking and stamping tools: This steel grade is used for blanking and stamping tools as its properties make it a good choice for molds and dies.

- 1.2379 Plastic molds: For applications which need a high wear resistance like for example the production of plastic parts Premium 1.2379 is an excellent choice.

- 1.2379 Knives and blades: This steel grade is sometimes used for high quality blades but its hardness makes sharpening them difficult.

Specific examples of use:

- cutting tools

- fine blanking tools

- dies

- punches

- thread rolling dies

- thread rolling rolls

- broaches

- milling cutters

- hobs

- press tools

- woodworking tools

- shear blades

- deep-drawing tools

- cold rolling

- measuring tools

- cold pilger mandrels

- plastic moulds

1.2379 Standard values

Chemical composition:

| C | Si | Mn | P | S | Cr | Mo | V |

|---|---|---|---|---|---|---|---|

| 1.45 - 1.6 | 0.1 - 0.6 | 0.2 - 0.6 | 0.0 - 0.03 | 0.0 - 0.03 | 11.0 - 13.0 | 0.7 - 1.0 | 0.7 - 1.0 |

Chemical designation:

1.2379

Working hardness:

57-62 HRC

Delivery condition:

max. 255 HB

1.2379 Physical Properties

What group of steel does the 1.2379 belong to?

- Tool steel

- Cold work steel

- Plastic mould steel

Is the 1.2379 a stainless steel?

Yes, with its mass fraction of 11 – 13 % chromium the 1.2379 (X153CrMoV12) can be classified as a stainless steel even tough it has its place among the tool steels.

1.2379 Corrosion resistance

On a scale where 1 is low and 6 is high, the corrosion resistance of 1.2379 is at 4. With a chromium content of 11 – 13 % it can be classified as a stainless steel, which has a certain degree of corrosion resistance, but not enough to classify this grade as corrosion-resistant.

Is the 1.2379 magnetisable?

As a ferrous metal, 1.2379 can be magnetised. Grinding, milling and eroding can be carried out on machines with magnetic adhesion, for example.

1.2379 Wear resistance

On a scale where 1 is low and 6 is high, the wear resistance of 1.2379 is 6, making it one of the best wear-resistant steel grades in our portfolio.

1.2379 Technical Properties

Is tool steel 1.2379 a knife steel?

1.2379 is often used for the manufacture of knife blades. 1.2379 has high wear resistance and hardness, which means that the cutting edges of the blades remain sharp for longer.

However, the steel also has a few disadvantages. Unlike other steel grades, 1.2379 knife steel is quite brittle. This means that under certain conditions, it is more susceptible to breakage or cracking. Due to its hardness, it can be more difficult to sharpen compared to other steel grades.

1.2379 Working hardness

The working hardness for 1.2379 is up to max. 62 HRC. Compared to other steel types, 1.2379 has a very high hardness giving it a high wear resistance. Depending on specific heat treatments, the working hardness can vary considerably.

1.2379 Steel density

The density of tool steel 1.2379 at a temperature of ~20 °C is approximately 7.7 g/cm³.

1.2379 Tensile strength

1.2379 has a tensile strength of approx. 860 N/mm2 upon delivery. The tensile strength indicates the maximum load capacity. To obtain this information, a tensile test is carried out to show how much force is required to stretch or elongate a sample before it breaks. The results can be viewed and taken from the stress-strain diagram.

1.2379 Yield strength

The yield strength of 1.2379 is approx. 420 N/mm2. This value indicates when the material exhibits plastic deformation under load.

1.2379 Machinability

On a scale where 1 is low and 6 is high, the 1.2379 receives a 1 for its machinability.

This steel is known for its high hardness and wear resistance. These properties are suitable for a wide range of tool applications, but they limit the machinability of this steel grade.

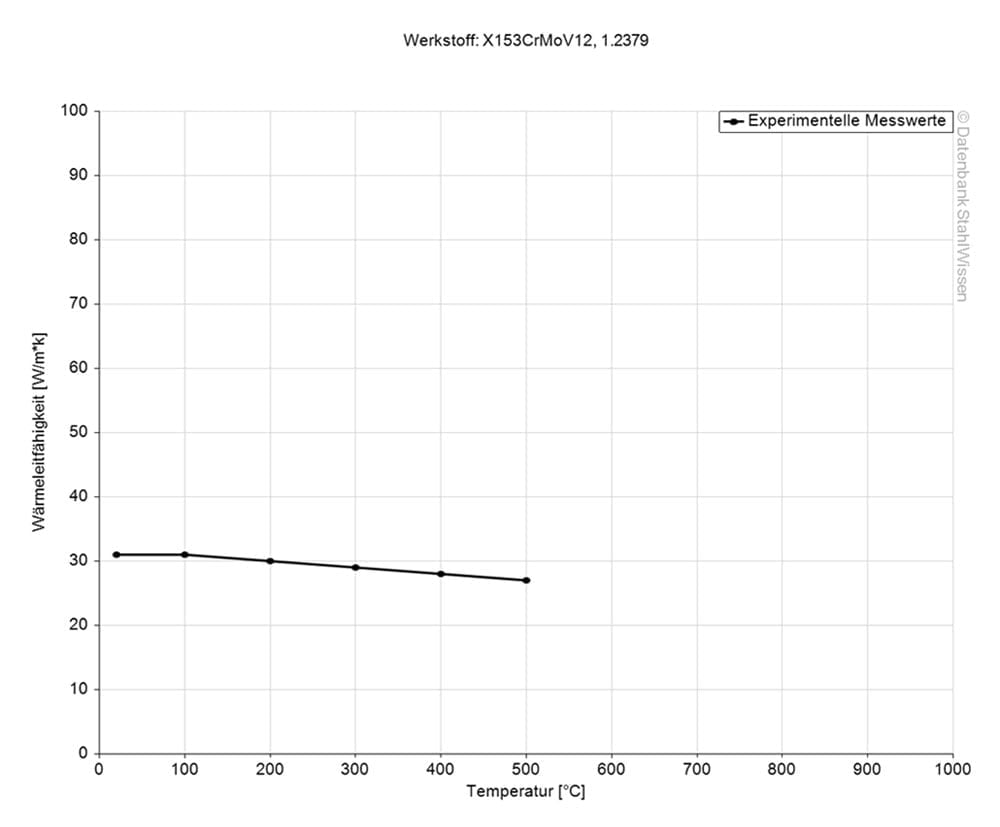

1.2379 Heat conductivity

For the 1.2379 the heat conductivity is typically between 16 – 25 W/(m*K) at room temperature.

As a physical propertiy the heat conductivity shows how well a material can conduct heat. This is important for applications which transfer heat or need to be temperature controlled. The following table shows the heat conductivity of the 1.2379 at different temperatures.

Heat conductivity

Value W/(m*K)

By temperature

16.7

20 °C

20.5

350 °C

24.2

700 °C

www.stahlwissen.de

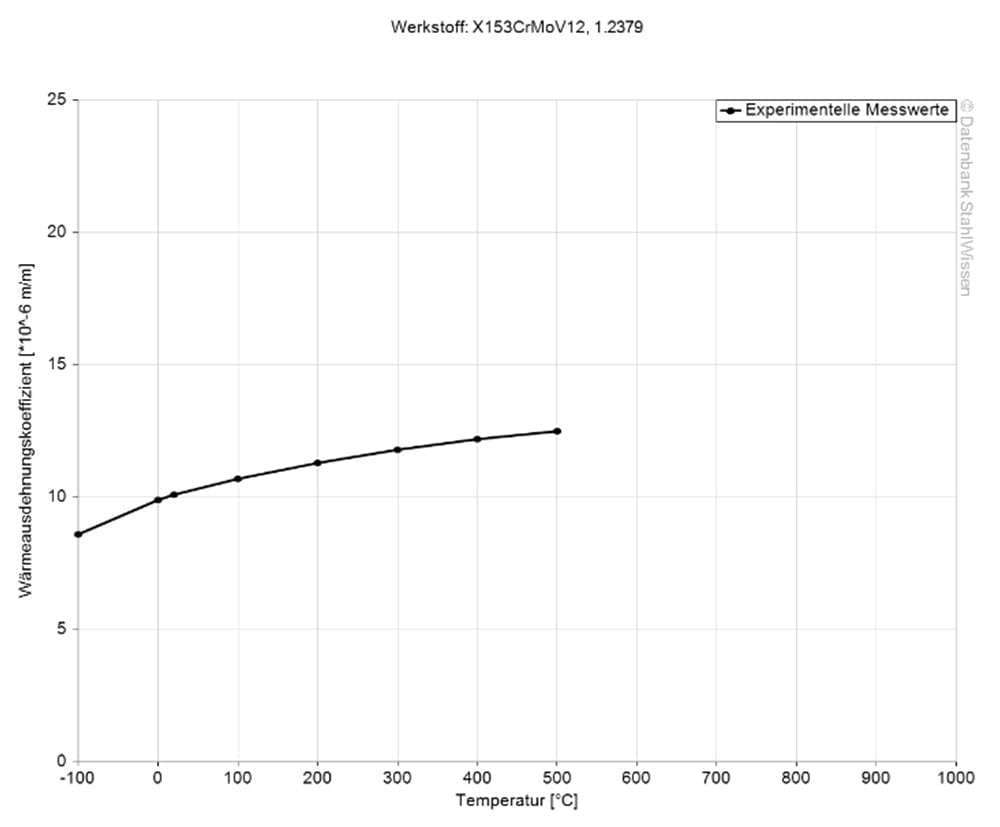

1.2379 Thermal expansion coefficient

The 1.2379 thermal expansion coefficient shows how much a material expands or contracts at temperature changes. This information can very important when working with high temperatures or during applications with stark temperature changes during an application.

Medium thermal expansion coefficient

Value 10-6m/(m*K)

Bei einer Temperatur von

10.5

20 – 100 °C

11.5

20 – 200 °C

11.9

20 – 300 °C

12.2

20 – 400 °C

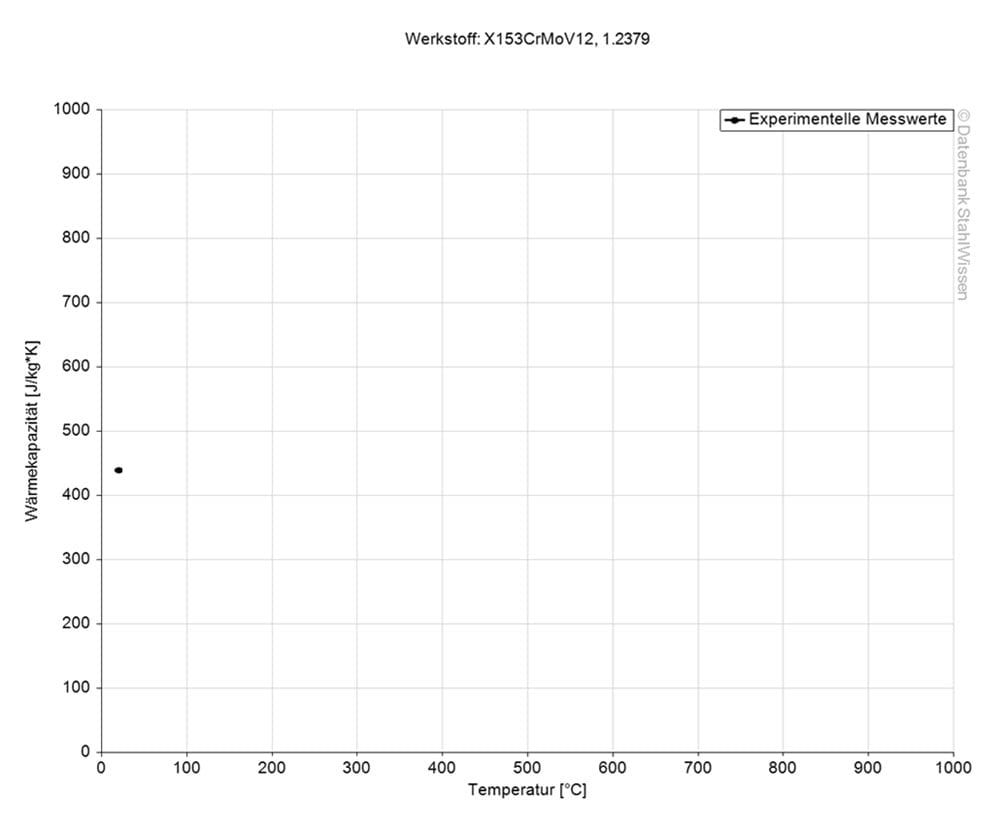

1.2379 Specific heat capacity

The specific heat capacity of 1.2379 is at 0,46 J/kg*K at room temperature.

The specfic heat capacity is a physical property which shows how much heat is needed to heat a specific amount of 1.2379 by 1 Kelvin.

1.2379 Specific electrical resistance

The specific electrical resistance can be found in the following table. Electrical conductivity is the reciprocal of specific electrical resistance.

Specific electrical resistance

Value (Ohm*mm²)/m

At a temperature of

~ 0.453

~ 20 °C

~ 0.515

~ 100 °C

~ 0.596

~ 200 °C

~ 0.695

~ 300 °C

~ 0.798

~ 400 °C

~ 0.908

~ 500 °C

HART-PRÄZ® – ALREADY HARDENED DIMENSIONS IN LENGTH OF 250 mm

AND 500 mm!

1.2379 Procedure

1.2379 Heat treatment

Heat treatment is used to determine material properties. It should therefore always be carried out with care. Properties such as strength, toughness, surface hardness and temperature resistance are determined, which in turn can extend/improve the service life of parts, tools and components.Heat treatment includes solution annealing, soft annealing, normalising, stress relief annealing, but also tempering, hardening and quenching or tempering. Tool steel 1.2379 is a secondary hardener. This material becomes harder through single or double tempering. During tempering, special carbides are precipitated and/or residual austenite is converted to martensite.

1.2379 Annealing

1.2379 should be protected and heated to a temperature of 830–860 °C, then held at this temperature for 2 hours. It is then cooled in the furnace at a rate of 10 °C per hour to a temperature of 650 °C, after which it can be left to cool freely in the air.

1.2379 Stress relieving

To stress relieve the 1.2379 heat it to a temperature of 600 – 650 °C after rough machining and maintain this temperature for two hours. Then slowly allow to cool to 500 °C. Finally, the workpiece can be left to cool further in the air.

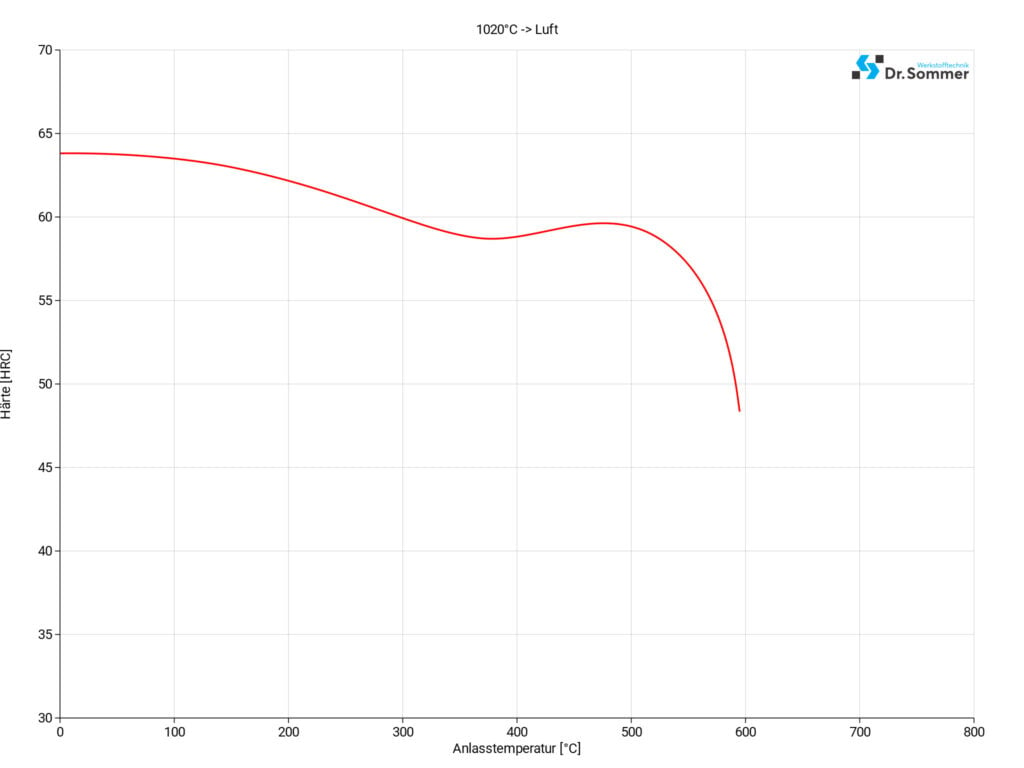

1.2379 Tempering

Tempering steel is a heat treatment process that follows hardening and reduces the hardness and strength of the steel while increasing its toughness. 1.2379 is normally hardened and then tempered to optimise its mechanical properties. The exact procedure may vary depending on the specific requirements of the application. In general, the steel is heated to a specified temperature, the parts are held at this temperature for a certain period of time, and the process is then completed by cooling the material again.

Select the tempering temperature to be reached, maintain the temperature in the oven for at least 2 hours, allow the material to cool twice, and allow the steel to cool to room temperature between tempering processes. The tempering temperature should not fall below 180 °C and should be maintained at the selected temperature for at least two hours.

You are able to find further information in the chart below:

1.2379 Heat treatment

In order to improve the technical properties of this steel grade, 1.2379 must undergo a heat treatment. The preheating time, holding time, temperature, atmosphere and quenching/cooling of the material are all important factors in this process.

1.2379 Sub-zero treatment

The preheating temperature for this steel grade is between 650 and 750 °C. A special container can be used here to protect workpieces from decarburisation and oxidation during hardening. The austenitising temperature for 1.2379 is between 1000 and 1050 °C. Maintain the temperature for one hour per 25 mm of maximum thickness. For a thickness of 75 mm, for example, the holding time is 3 hours.

Remove the workpiece from the container, if one was used, and cool it slowly in the furnace to a temperature of approx. 65°C. The workpiece should then be tempered immediately. As an oil-hardening steel, workpieces can also be cooled in oil. Quenching in oil can achieve higher hardness and wear resistance.

Before immersing workpieces in the quenching medium oil, the oil should be preheated to a temperature of approx. 66 °C. The parts are then quenched from a temperature of 1035 °C and kept in the oil until the temperature reaches approx. 535 – 650 °C. At this temperature, the parts can be removed from the oil and further cooled in the air.

1.2379 Tiefkühlbehandlung

Since changes in volume can occur over time, workpieces that require maximum dimensional stability, such as measuring instruments or structural parts, should be treated below the freezing point. After quenching, the workpiece should be kept at a temperature between -70 and -80 °C for 3 to 4 hours, followed by a series of tempering processes. Tempering in turn influences the abrasion resistance and service life of the respective workpieces. This treatment increases the hardness by 1 to 3 HRC. Due to the risk of cracking, this process should not be used on intricate shapes.

1.2379 Quenching

The following are widely used quenching methods for this type of steel:

- Oil for plain geometries

- Vacuum

- Forced air/air/gas

- Hot bath or fluidised bed at 180 °C – 500 °C, then allow to cool in air

1.2379 can be hardened through in all common sizes. Make sure that the material is tempered immediately once the temperature of the workpiece has reached 50–70 °C.

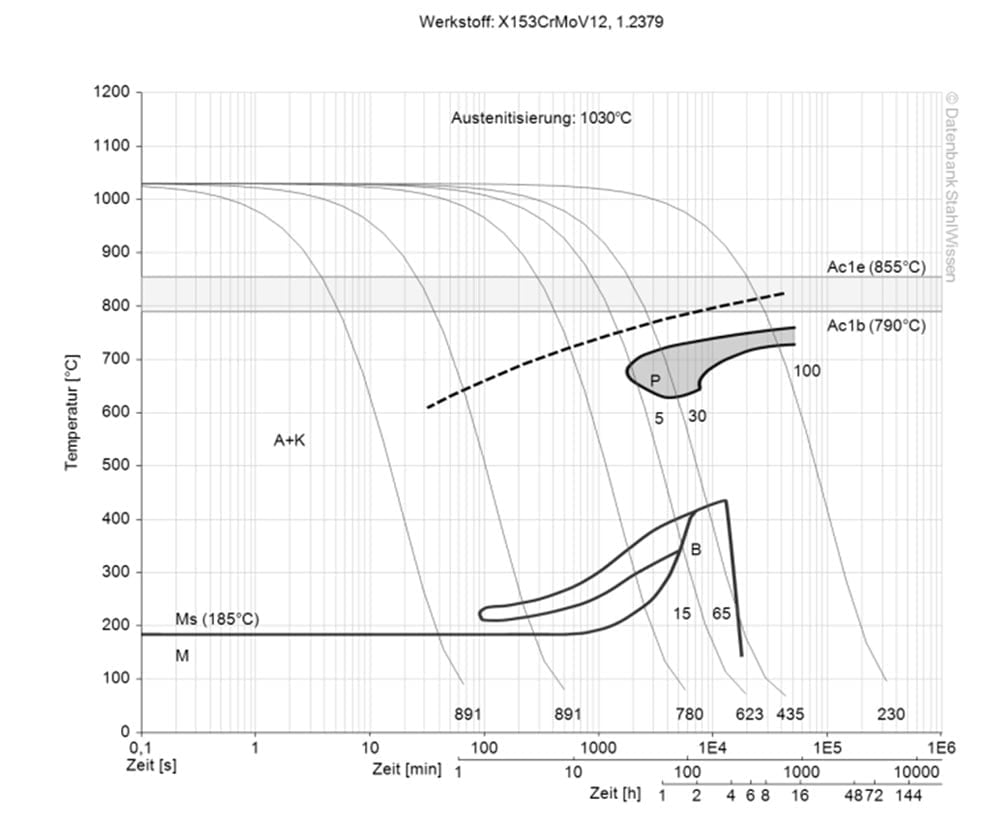

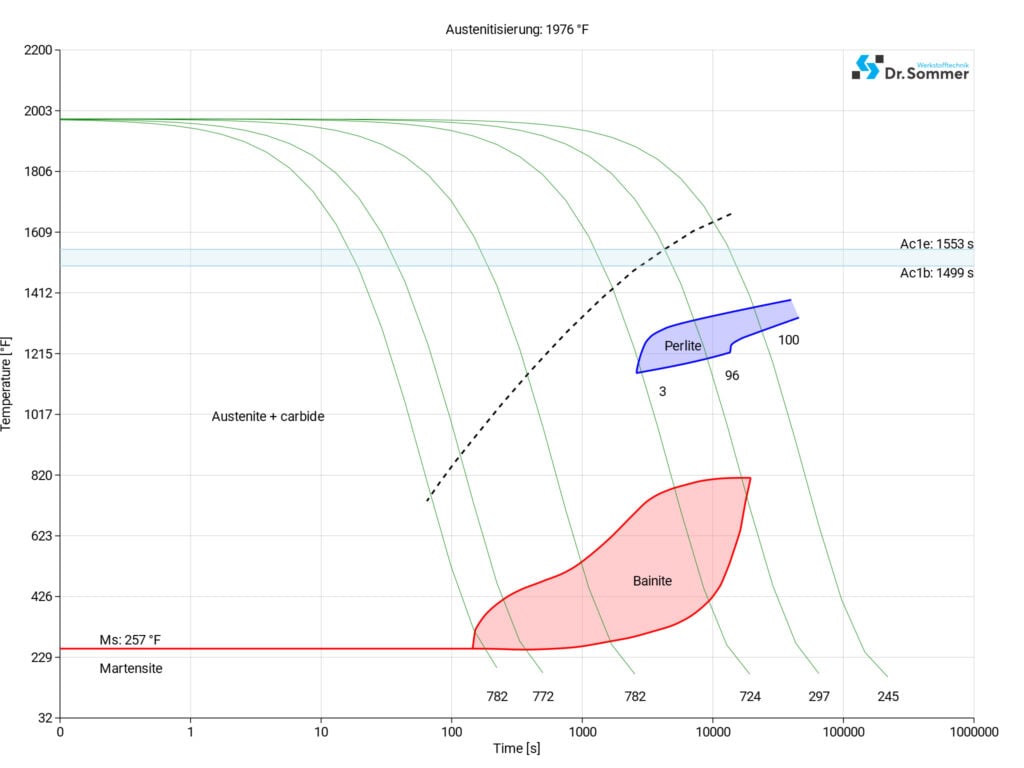

1.2379 Continuous TTT-diagram

This diagram shows the micro changes at different temperatures which are important during heat treatment. They show the optimum condition for the hardening, annealing and normalizing process.

The TTT-diagram typically shows the different phases of steel as well as the time and temperature at which certain changes occur (e.g. pearlite, bainite and martensite).

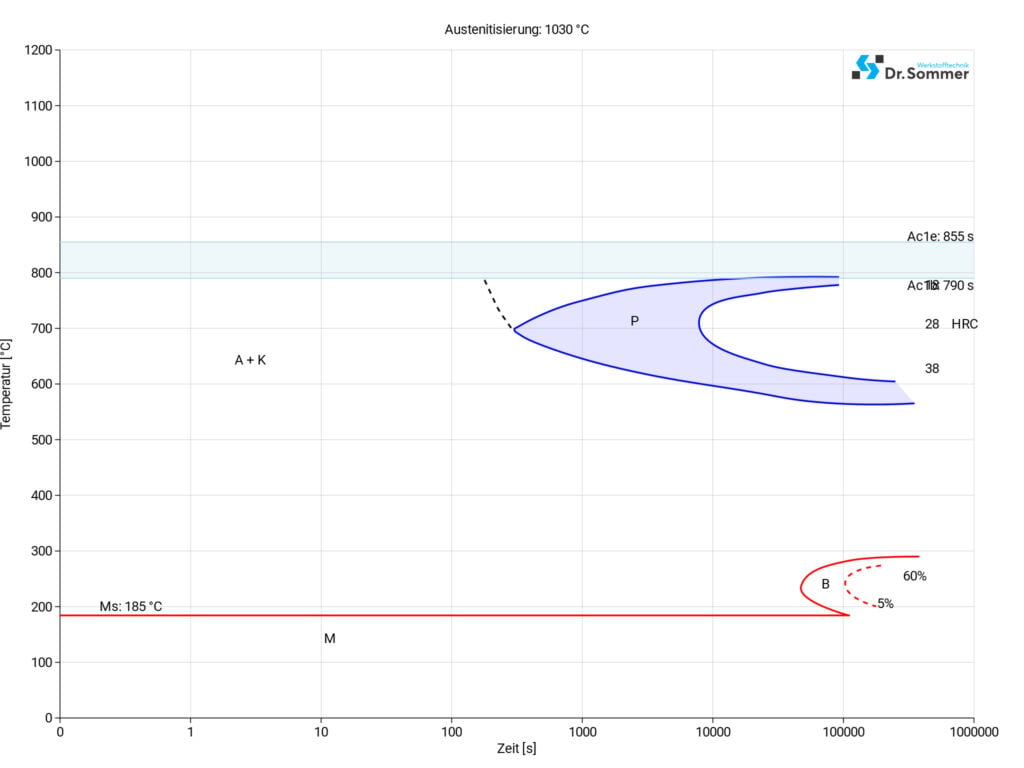

1.2379 Isothermal TTT-diagram

This diagram shows the structural changes at micro level over time at a constant temperature. It shows at what temperature and after what time different phases, e.g., perlite, martensite or bainite start to build.

1.2379 surface treatment

1.2379 Nitriding

1.2379 is tempering resistant even at higher temperatures and can be nitrided without loss of hardness.

The nitriding process improves the already high hardness and wear resistance of 1.2379, which can be advantageous for applications where these properties are required for the surface.

The nitriding process should be carefully monitored to ensure that the required properties are achieved and to prevent possible problems such as deformation or cracking of the steel.

1.2379 PVD and CVD

The PVD and CVD processes coat the material with a thin protective layer. This protective layer can improve corrosion resistance, wear resistance and reduce friction.

- PVD – physical vapour deposition

- CVD – chemical vapour deposition

1.2379 Processing

1.2379 Electrical Discharge Machining (EDM)

Eroding can be carried out for this material in a hardened or tempered state, after which the recast layer should be completely removed, e.g. by grinding and polishing. The pieces can then be tempered again (at a temperature 25 °C below the previous tempering temperature) and held at this temperature for two hours.

1.2379 Machining allowance / dimensional changes

Dimensional changes during hardening and tempering should be taken into account and an allowance of 0.15 % per side should be added if workpieces are stress-relieved between initial and further processing. If no stress reliefing is carried out, the machining allowance should be increased accordingly.

1.2379 Forging

This grade is forgeable. Preheat the workpiece to a temperature of 700–760 °C, then increase the heat to a forging temperature of 1010–1050 °C. Do not allow the temperature to fall below 925 °C and reheat if necessary. After completion, the parts are cooled evenly and slowly to approx. 760–815 °C in ash, lime or similar and then tempered as quickly as possible.

1.2379 Welding

1.2379 can be welded, but this should be avoided if possible. Welding this material grade can be challenging and should be carried out with the necessary care and expertise. As 1.2379 has a high hardness and a high carbon content, this steel is prone to cracking during welding.

When welding tool steel such as 1.2379, good results can be achieved if the correct precautions are taken during the welding process.

Preheating: To avoid and reduce stresses within the steel, the material should be preheated to reduce the possibility of cracking.

Typically, this steel grade is preheated to a temperature of 200–300 °C.

Welding consumables: When preparing the joint/weld, it is very important to select the appropriate welding consumables and welding processes. The filler is often selected to be compatible with 1.2379 or to have a similar composition in order to achieve the best possible results. When polishing or photo etching 1.2379, it is necessary to work with suitable electrodes of the appropriate composition.

Tempering: After welding, the parts should be cooled slowly and then tempered to reduce hardness and increase tensile strength again. Tempering helps to prevent cracking.