1.2714 - AT A GLANCE

What kind of steel is the 1.2714?

As an oil hardening chrome nickel tool steel, 1.2714 is often used for applications needing a greater toughness. This steel grade has a better toughness due to the nickel content, at the same time retaining good hardness and wear resistance. With its lower carbon content, it has a slightly better shock resistance in comparison to higher alloyed steels and can be used if wear resistance is secondary to increased toughness.

Properties

1.2714 tool steel has a unique blend of properties, its high carbon content makes it a good choice for applications needing a high wear resistance. Its exceptional toughness gives the 1.2714 a resistance to impacts and makes it less prone to chipping and breaking.

Possible corrosion should be managed and should be considered when choosing the 1.2714 as well as the correct heat treatment needs to be chosen as many of the properties of the 1.2714 may be affected when not heat treated correctly.

Practically, this means:

- High carbon content

- For applications that require high wear resistance

- Exceptional toughness makes it impact resistant

- Less susceptible to chipping and cracking

- High tempering resistance

- Good through hardenability

- Can be nitrided and eroded

- Working hardness is in the range of 40 – 54 HRC

- High compressive strength

- Water coolable

- High impact strengt

Applications

1.2714 tool steel can withstand sudden stresses and impacts, has a good toughness and wear resistance as well as a reasonable hardness. These properties lend themselves to applications like knives and blades, cold work tools, bearings, bushings, woodwork tools, spindles, cams, and springs.

- Forging dies

- Slides

- Punch heads

- Extruding stamps

- Press tools

- Hot shear knives

- Extrusion press tools

- Support tools

- Pressure plates

- Stamping heads

- Extrusion punches

- Moulding presses

- Hot shearing blades

- Hot punches

- Extrusion tools

- Forging saddles

- Die holders

- Support tools

- Press mandrel holders

- Tool holders

- Pressure plates

- Armoured cutting plates

- Lugs

- Springs

- Spindles

- Cold-forming tools

- Ball bearings

- Bushings

- woodworking tools

1.2714 STANDARD VALUES

Chemical composition:

| C | Si | Mn | P | S | Cr | Mo | Ni | V |

|---|---|---|---|---|---|---|---|---|

| 0.5 - 0.6 | 0.1 - 0.4 | 0.6 - 0.9 | 0.0 - 0.03 | 0.0 0.03 | 0.8 - 1.2 | 0.35 - 0.55 | 1.5 - 1.8 | 0.05 - 0.15 |

Chemical designation:

55NiCrMoV7

Working hardness:

ca. 40-54 HRC

Delivery condition:

max. 250 HB

1.2714 PHYSICAL PROPERTIES

What group of steel does the 1.2714 belong to?

- Tool steel

- Hot work steel

Is the 1.2714 a stainless steel?

No, 1.2714 is not stainless steel. 1.2714 is a tool steel. Stainless steel has a mass fraction of 10.5% chromium, while 1.2714 has a mass fraction of 0.8 to 1.2% chromium.

Is the 1.2714 corrosion resistant?

1.2714 is not a corrosion-resistant steel. To be corrosion-resistant, steel must have a chromium content of at least 10.5% to be corrosion-resistant like stainless steel.

Although 1.2714 has a certain degree of corrosion resistance, it will corrode when exposed to corrosive environments or moisture. To protect this steel grade, it can be coated or the surface can be additionally treated against corrosion.

Is the 1.2714 magnetisable

As an iron-containing material, 1.2714 can be magnetised; that is especially true for materials in a martensitic state.

1.2714 Hot work

Unlike cold working, hot working, hot rolling, forging and extruding does not harden 1.2714 tool steel. This reduces porosity, improves the overall structure and allows the material to be formed over large areas.

Care must be taken during hot forming to avoid a scale layer, possible deformation and excessive grain growth.

1.2714 Cold work

Cold working, cold drawing, rolling and cold forging can cause work hardening, achieving tighter tolerances and a smooth surface without further processing.

The increased hardness can in turn promote crack formation, but also lead to increased tool wear. The internal stresses arising during this process should ideally be compensated by stress relief annealing.

1.2714 Wear resistance

The wear resistance of the 1.2714 is at 2 on a scale where 1 is low and 6 is high.

1.2714 TECHNICAL PROPERTIES

1.2714 Working hardness

The working hardness for tool steel 1.2714 is in the range of 40–54 HRC.

1.2714 Steel density

At room temperature, the density of 1.2714 tool steel is typically 7.8 g/cm3.

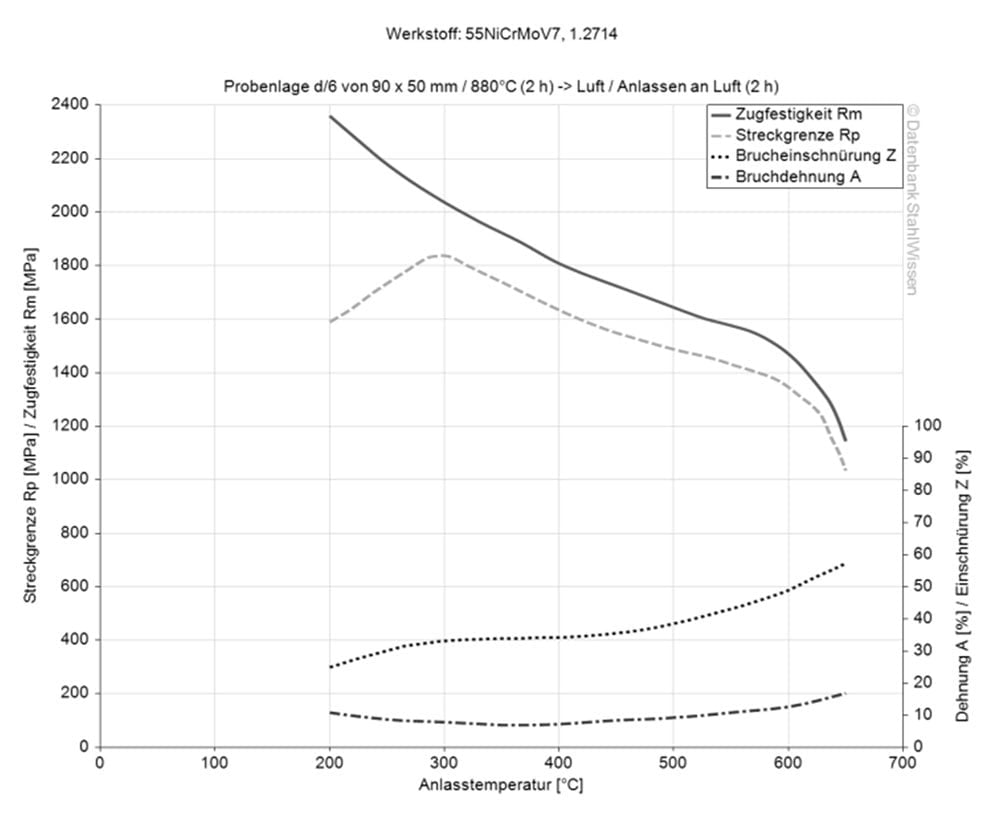

1.2714 Tensile strength

1.2714 tool steel has a tensile strength of approx. 850 N/mm2. The tensile strength indicates the maximum load capacity. To obtain this information, a tensile test is carried out to show how much force is required to stretch or elongate a sample before it breaks.

1.2714 Machinability

On a scale where 1 is low and 6 is high, the material grade 1.2714 receives a 4 for its machinability.

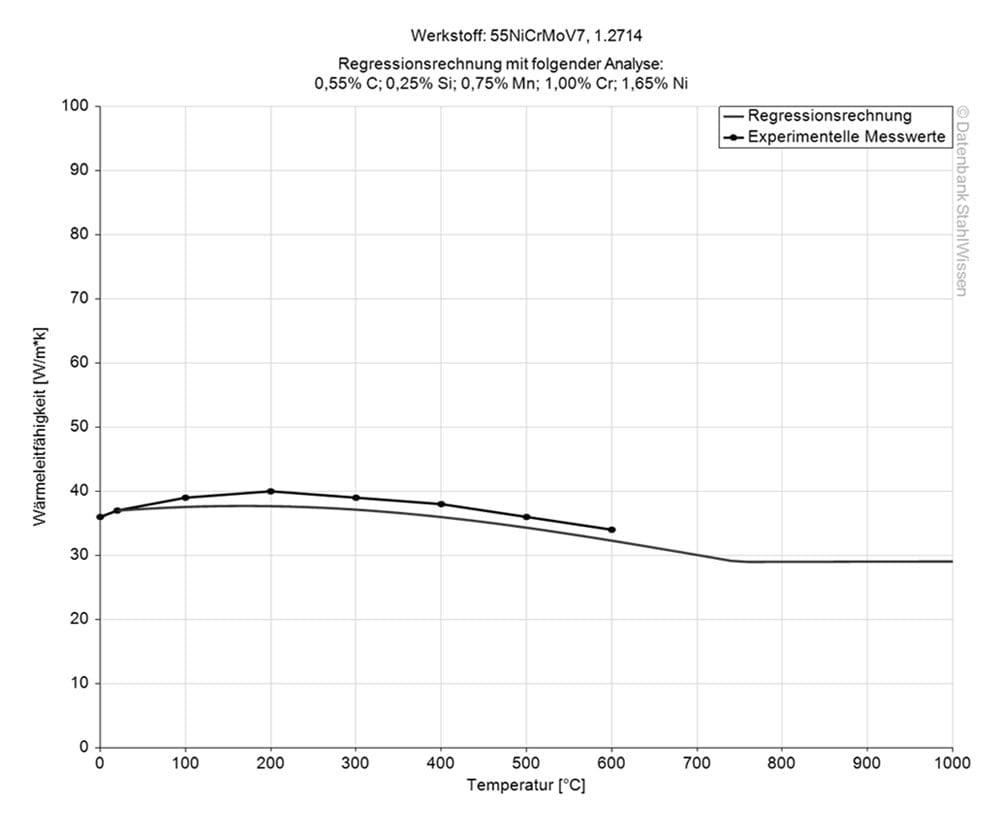

1.2714 Heat conductivity

The following table shows the thermal conductivity of tool steel 1.2714 at different temperatures.

Heat conductivity

Value (W/m*K)

At a temeprature of

36.0

20 °C

38.0

350 °C

35.0

700 °C

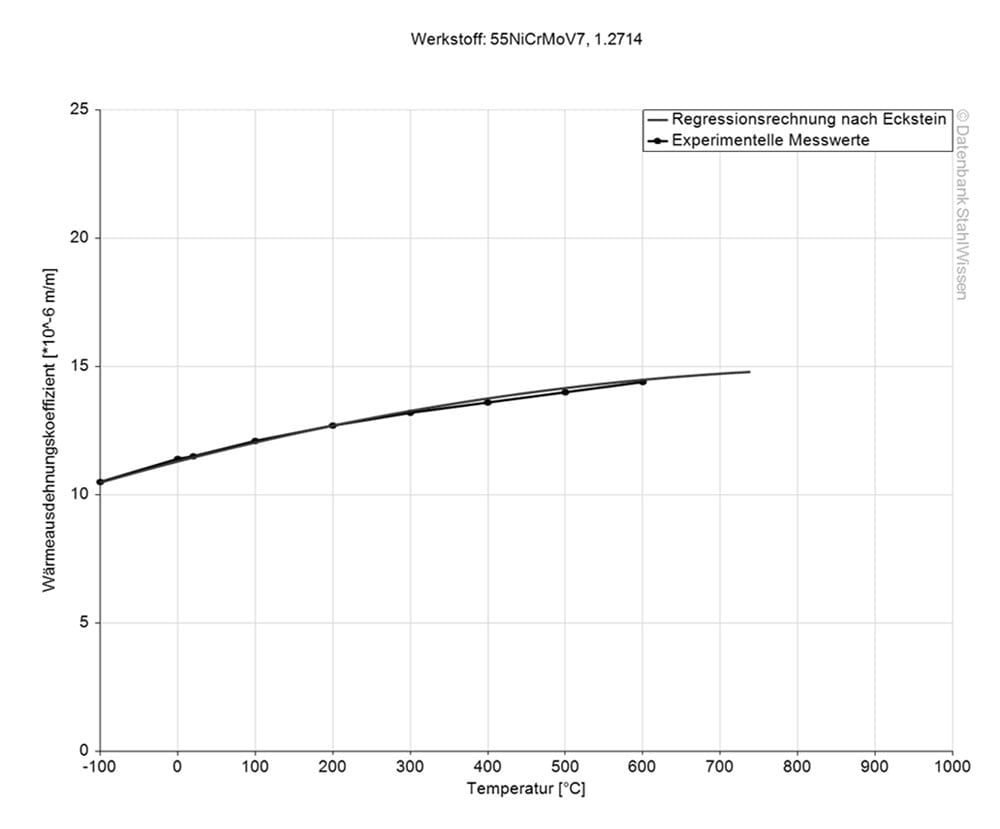

1.2714 Thermal expansion coefficient

The thermal expansion coefficient indicates how much the material can expand or contract when the temperature changes. This is very important information, especially when working with high temperatures or when there are significant temperature fluctuations during use.

Medium thermal expansion coefficient

Wert 10-6m/(m*K)

At a temeprature of

12.2

20 – 100 °C

13.0

20 – 200 °C

13.3

20 – 300 °C

13.7

20 – 400 °C

14.2

20 – 500 °C

14.4

20 – 600 °C

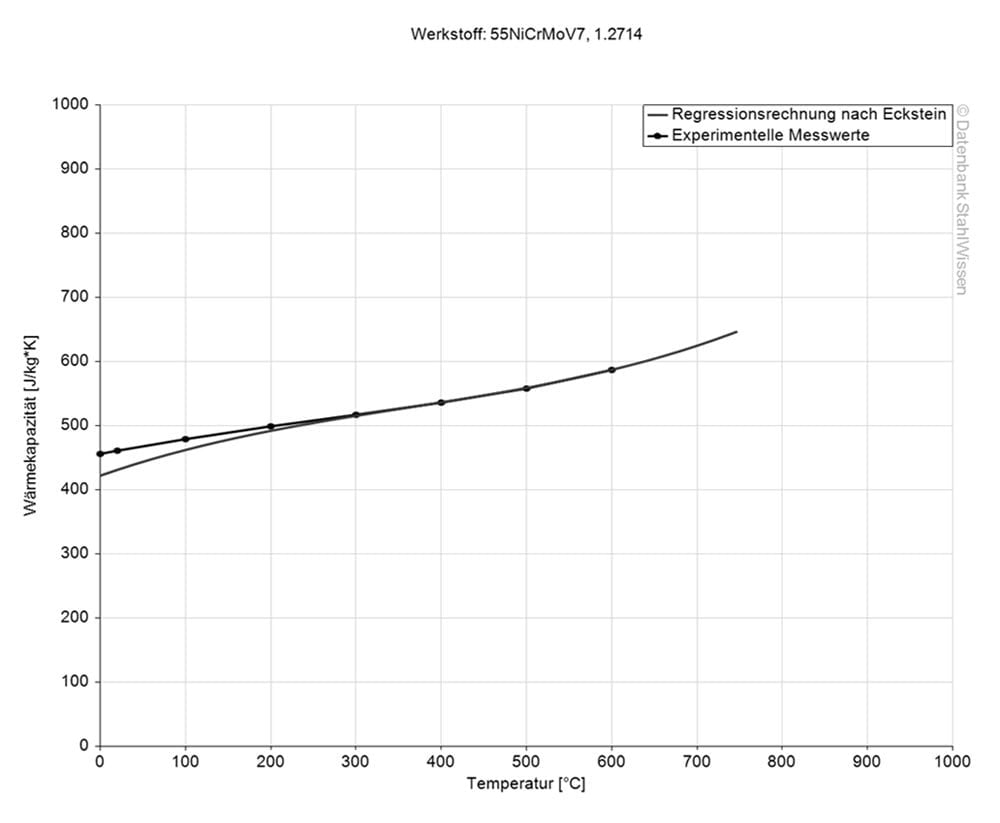

1.2714 Specific heat capacity

The specific heat capacity of 1.2714 at room temperature is 0.46 J/g*K. This value indicates how much heat is required to heat a specific amount of 1.2714 material by 1 Kelvin.

1.2714 Specific electrical resistance

Den spezifischen elektrischen Widerstand können Sie der folgenden Tabelle entnehmen. Die elektrische Leitfähigkeit ist der Gegenwert des spezifischen elektrischen Widerstands.

Table of the specific electrical resistivity

Value (Ohm*mm2)/m)

At a temperature of

0,3

20 °C

1.2714 Elastizitätsmodul (e-Modul)

Das Spannungs- und Dehnungsmodul oder das Elastizitätsmodul (Youngscher Modul) für Werkzeugstahl 1.2714 liegt bei 190 – 210 kN/mm2.

HEART AND SOUL IN STEEL!

1.2714 PROCEDURE

2714 Heat treatment

Material properties are determined during heat treatment. Therefore, this process should always be carried out with care. Properties such as strength, toughness, surface hardness and temperature resistance are determined, which in turn can extend/improve the service life of parts, tools and components.

Heat treatment includes solution annealing, soft annealing, normalising, stress relief annealing, but also tempering, hardening and quenching or tempering.

1.2714 Annealing

Heat material 1.2714 slowly and evenly to a temperature of 650–700 °C and maintain this temperature for 1 hour per 25 mm thickness, but for at least 2 hours. Then cool slowly in the furnace at 10 °C per hour to 538 °C, then allow to cool in air.

To improve machinability, cool the workpiece slowly in the furnace to a temperature of 677 °C, hold it at this temperature for 8 hours and then cool it in air to room temperature.

1.2714 Stress relieving

Heat the workpieces evenly to a temperature range of 566–677 °C and maintain this temperature for two hours. Complete this process by allowing the parts to cool in the furnace to 482 °C and then to ambient temperature in the air.

1.2714 Normalising

Normalising 1.2714 can improve machinability and mechanical properties, as well as reduce internal stresses, as normalising gives it a finer and more uniform pearlitic grain structure.

1.2714 Hardening

Heat the parts evenly to a temperature of 677–732 °C, then continue with the austenitising temperature of 816–843 °C and maintain this temperature for 10–30 minutes. To protect the material from excessive scale or decarburisation, either heat the workpieces in neutral salt, pack them in cast iron chips or spent coke, or heat them in a protective atmosphere or vacuum furnace.

1.2714 Quenching

- Oil, heated – the pieces should be cooled to 50–65°C or until they can be held in the hand without difficulty, and then the material should be tempered immediately.

- Air – this quenching method is used for workpieces smaller than 25 mm. Air quenching is a safer option for small and delicate workpieces, as they are less deformed by air quenching than by quenching with oil.

1.2714 Tempering

To avoid cracks, start tempering 1.2714 immediately after quenching. Maintain the selected tempering temperature for 1 hour per 25 mm thickness, but for at least 4 hours, and then cool the material to room temperature. 1.2714 can be tempered in a temperature range of 232 – 427 °C without becoming brittle. To minimise internal stresses in workpieces with a cross-section greater than 150 mm and/or to improve the stability of tools that are machined after heat treatment, it is recommended to hold the material for 8 to 10 hours.

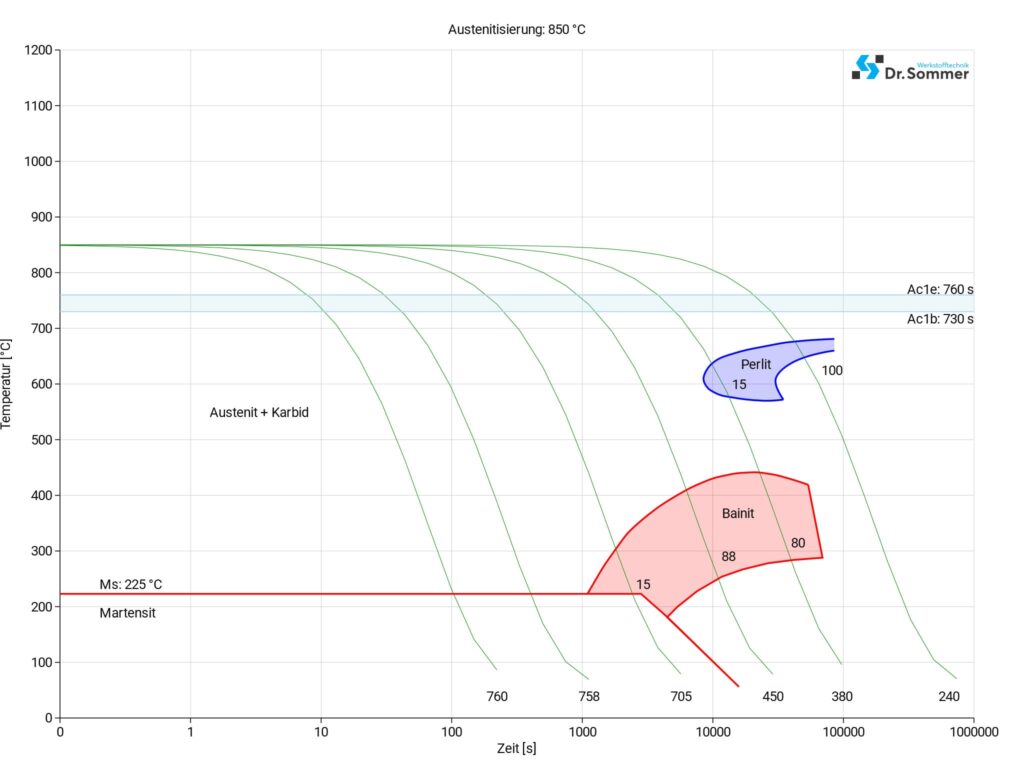

1.2714 Continuous TTT-diagram

This diagram shows micro-changes over time at different temperatures. These are important in heat treatment because they provide information about the optimal conditions for processes such as hardening, annealing and normalising.

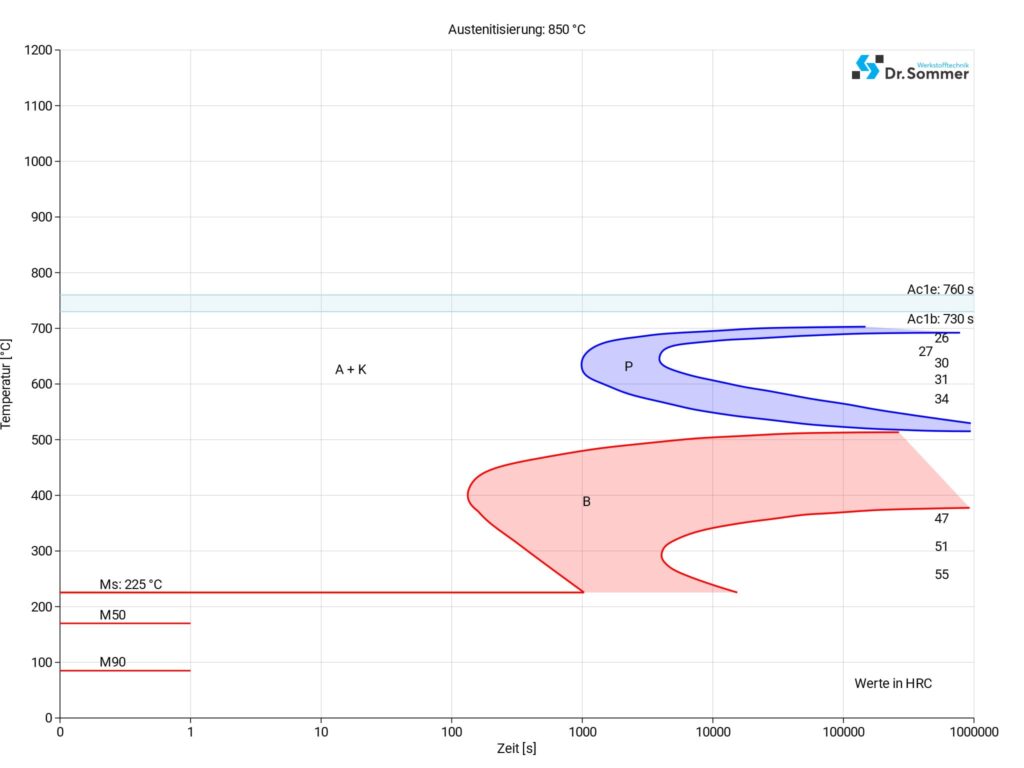

1.2714 Isothermal TTT-diagram

This diagram shows the structural changes at the micro level over time at a constant temperature. It shows at what temperature and after what time different phases, e.g. perlite, martensite or bainite, begin to form.

1.2714 SURFACE TREATMENT

The choice of surface treatment depends on the requirements, the environment in which the workpieces/tools are used, the required properties and the expected loads.

To improve its performance and service life, the following surface treatments can be applied to 1.2714.

1.2714 Nitriding

During nitriding, nitrogen is diffused into the surface to increase surface hardness and improve corrosion resistance. Since low temperatures are used in this process, the likelihood of deformation is low. If nitriding is not carried out properly, the material can become brittle.

1.2714 Carburising

During this process, carbon is introduced into the surface to improve wear resistance and surface hardness. As this is a high-temperature process, caution is required as it can alter the material properties and cause the material to warp.

1.2714 Black oxide coating (blueing)

Blueing is often used for aesthetic reasons, as it provides a black-blue finish that is frequently used for tools or firearms because it reduces light reflection from the surface.

1.2714 PVD- und CVD

Both PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition) coatings apply a thin layer to the material surface that can increase wear resistance or reduce friction.

1.2714 Shot peening

Shot peening involves blasting small spherical particles made of glass, ceramic or steel at high speed onto the surface of the material, leaving behind tiny indentations that replace the tensile stress on the surface with a residual compressive layer. Shot peening strengthens the material and makes the surface more resistant, preventing fatigue and stress corrosion.

1.2714 PROCESSING

1.2714 Electrical Discharge Machining (EDM)

With its good electrical conductivity and hardness, 1.2714 can be eroded. Erosion is often used to achieve tight tolerances or to machine intricate details from hardened material.

1.2714 Machining allowance / dimensional changes

Like most metals, 1.2714 can contract and expand when heated or cooled. Phase changes, internal stresses and decarburisation can also cause dimensional changes which can affect the properties of this steel grade. To prevent this, it may be advantageous to preheat the workpieces.

Controlled heating and cooling, stress relief and the avoidance of overheating, as well as the use of the correct quenching medium, can reduce the risk of thermal shock and undesirable dimensional changes, such as warping or deformation, as well as crack formation, which may result in a project having to be started all over again.

1.2714 Tiefkühlbehandlung

Die Tiefkühlbehandlung kann als Erweiterung des Abschreckens nach der Austenitisierung und vor dem Anlassen durchgeführt werden.

Eine Tiefkühlbehandlung kann die Härte und Zähigkeit des 1.2714 verbessern, seine Verschleißfestigkeit und Stabilität erhöhen – alles Vorteile, die den Werkzeugen und Bauteilen eine längere Lebensdauer verleihen können. Allerdings müssen Behandlungsdauer und die Abkühlgeschwindigkeit berücksichtigt werden, wenn entschieden wird, ob eine Behandlung unter dem Gefrierpunkt für diese Materialsorte vorteilhaft ist.

1.2714 Forging

Heat the workpiece slowly and evenly to a temperature of 982–1038 °C. Do not allow the temperature to fall below 871 °C and reheat the material as often as necessary. Once the forging process is complete, cool the workpieces slowly in lime, dry ash or in the furnace.

1.2714 Welding

1.2714 is generally weldable. The surfaces should be free of grease and dirt, as well as rust and paint. To avoid cracking, excessive hardening and loss of properties, the material should be preheated slowly. Similar fillers can be added to the base material and the welding process should be selected according to the specific requirements.

Overheating can lead to grain growth, which in turn weakens the weld seam and can be avoided with the right combination of current, voltage and travel speed. To relieve stresses that occur during welding, the material can be tempered after welding.