1.2738 - AT A GLANCE

What kind of steel is the 1.2738?

The 1.2738 is a plastic mold steel due to its good machinability and excellent polishability. The added nickel in this tool steel grade ensures a more uniform hardness throughout the material. 1.2738 can be used in a wide variety of applications as it has a good balance of hardness and toughness which gives it an advantage resisting cracking and breaking when used for impact applications or applications that will apply high stresses.

Properties

.2738 has a good combination of properties giving it the right blend of hardness, toughness and machinability. These properties make the 1.2738 a great choice for molds and precision tools.

- Tool steel (pre-tempered)

- Focus on plastic mold construction

- Better through-hardenability due to nickel addition

- Low sulphur

- Good polishability

- Grainable

- Hard chromium platable

Applications

Its increased hardness, wear resistance, edge stability, good machinability and excellent polisability make the P20+Ni a good choice for molds and dies and high precision tooling. P20+Ni has a longer service life with its uniform strength and high toughness.

- Plastic molds

- Molding frames

- Die casting molds

- Dies

- Forging tools

- Metal extrusion tools

- Tube presses

- Hydroforming tool

- Moulds for bumpers

- Automotive industry

- Plant engineering

1.2738 STANDARD VALUES

Chemical composition:

| C | Si | Mn | P | S | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|

| 0.35 - 0.45 | 0.2 - 0.4 | 1.3 - 1.6 | 0.0 - 0.03 | 0.0 - 0.03 | 1.8 - 2.1 | 0.15 - 0.25 | 0.9 - 1.2 |

Chemical designation:

40CrMnNiMo8-6-4

Working hardness:

ca. 32 HRC (Delivery condition tempered) bis 50 HRC

Delivery condition:

max. 325 HB

1.2738 PHYSICAL PROPERTIES

What group of steel does the 1.2738 belong to?

- Tool steel

- Cold work steel

- Plastic mould steel

Is the 1.2738 a stainless steel?

To be classified as stainless steel, the material must have a minimum chromium content of 10.5%. 1.2738 has a chromium content of 1.8–2.1% and therefore cannot be classified as stainless steel.

Is the 1.2738 corrosion resistant?

Tool steel 1.2738 has a certain degree of corrosion resistance. However, to be completely corrosion resistant, the material must have a mass fraction of at least 10.5%, which 1.2738 does not have with a chromium content of 1.8–2.1%.

Is the 1.2738 magnetisable?

1.2738 is a ferromagnetic steel that can be magnetised. Due to its nickel content, its magnetisability can be slightly reduced. To machine this material, it can be clamped to machines with magnetic hold for grinding and milling.

1.2738 Wear resistance

The wear resistance for 1.2738 is on a scale of 1 to 6, where 1 is low and 6 is high, at 3.

1.2738 TECHNICAL PROPERTIES

Is the 1.2738 a knife steel?

1.2738 is suitable for knife production as it offers a good balance between toughness and hardness, good wear resistance and is easy to machine. Knives made from 1.2738 can withstand impacts, do not splinter easily, have good cutting properties and can be sharpened relatively well. Knives made from this material should be given an additional surface treatment or coating to prevent rust formation when used in corrosive or wet environments.

1.2738 Working hardness

The working hardness for 1.2738 is in the range of 32 HRC (supplied condition, tempered) – 50 HRC.

1.2738 Steel density

Typically, the density of 1.2738 tool steel is 7.80 g/cm3 at room temperature.

1.2738 Tensile strength

1.2738 has a tensile strength of approx. 1100 N/mm2 upon delivery. The tensile strength indicates the maximum load capacity. To obtain this information, a tensile test is carried out to show how much force is required to stretch or elongate a sample before it breaks.

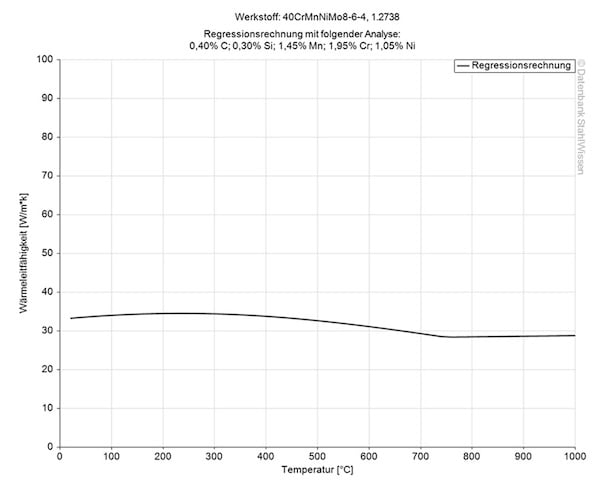

1.2738 Heat conductivity

The thermal conductivity for 1.2738 is 34.5 W/(m*K) at room temperature.

Heat conductivity

Value

At a temeprature of

34.5

20 °C

33.5

350 °C

32.0

700 °C

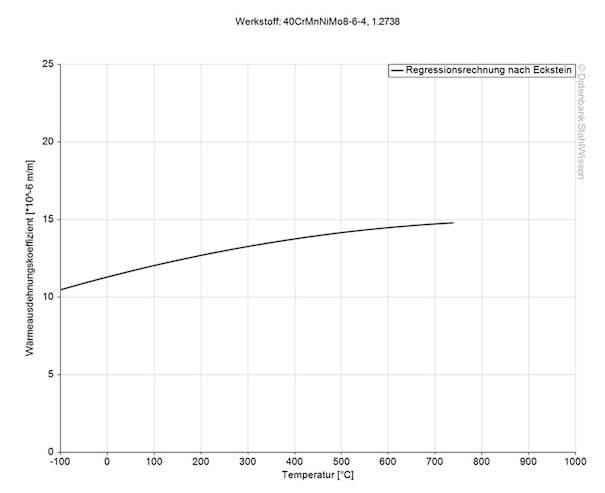

1.2738 Thermal expansion coefficient

The thermal expansion coefficient indicates how much the material can expand or contract when the temperature changes. This is very important information, especially when working with high temperatures or when there are significant temperature fluctuations during use.

Medium thermal expansion coefficient

At a temeprature of

11.1

20 – 100 °C

12.9

20 – 200 °C

13.4

20 – 300 °C

13.8

20 – 400 °C

14.2

20 – 500°C

14.6

20 – 600°C

14.9

20 – 700 °C

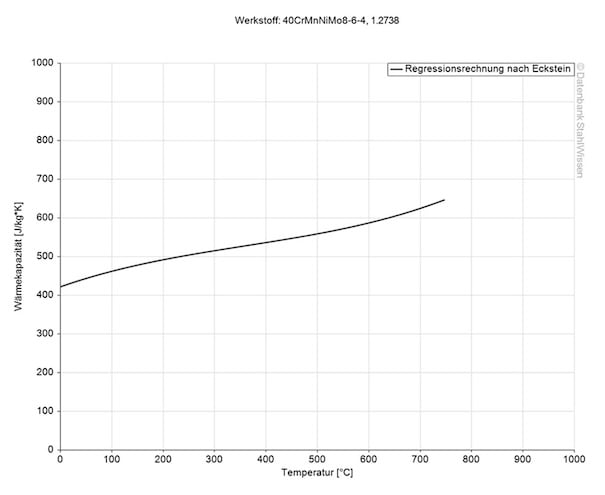

1.2738 Specific heat capacity

The specific heat capacity of tool steel at room temperature is 0.46 J/kg*K. This value indicates how much heat is required to heat a certain amount of material by 1 Kelvin.

1.2738 Elastizitätsmodul (e-Modul)

Das Spannungs- und Dehnungsmodul oder das Elastizitätsmodul (Youngscher Modul) für Werkzeugstahl 1.2738 liegt bei 205 kN/mm2.

1.2738 PROCEDURE

1.2738 Heat treatment

As this steel grade is supplied in a tempered condition, heat treatment is not normally required. However, if higher hardness or rehardening is required, please follow the steps below. The purpose of a heat treatment is to increase hardness and wear resistance. The process should be carried out with care to avoid creating or reintroducing stresses or other defects.

1.2738 Annealing

Heat the workpieces to a temperature of 710–740 °C and maintain this temperature for 2–5 hours. The holding time is usually around 1 hour per 25 mm of thickness. Then slowly cool the pieces in the furnace by 10–20 °C per hour to 600 °C. Allow to cool further in the air.

1.2738 Stress relieving

Heat the component evenly to a temperature of 500–550°C and maintain this temperature. Finally, allow the components to cool slowly in the furnace. Slow cooling of the components prevents the formation of new stresses in the components. Stress relief annealing helps to maintain dimensional stability and extends the service life of tools.

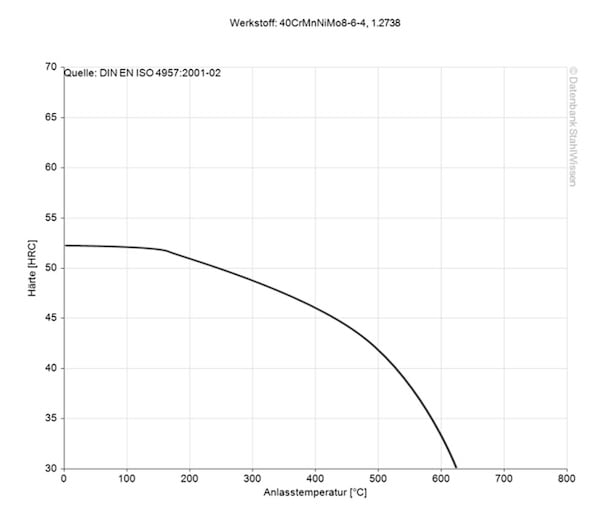

1.2738 Tempering

Select the appropriate starting temperature and heat the material slowly to this temperature immediately after hardening. Maintain this temperature for one hour per 25 mm of thickness, but for at least 2 hours, and then allow to cool in air.

Choosing the right tempering temperature determines the balance between hardness and toughness. If a higher temperature is used, the workpiece will be more tough, but its hardness will be reduced.

1.2738 Hardening

Evenly heat the material to a temperature of 840–870 °C, hold for 15–30 minutes, then quench.

1.2738 Flame and induction hardening

As a plastic mould steel, this grade can be flame or induction hardened to reduce surface damage and achieve a hardness of approx. 50 HRC.

Flame hardening should be carried out evenly after preliminary processing, as uneven heating can lead to deformation or cracks.

Compared to flame hardening, induction hardening is a controlled, faster and deeper hardening process. It is recommended to temper 1.2738 after flame or induction hardening, see section ‘Tempering’ for more information. To achieve the best results and maintain all the properties offered, these processes should be controlled and carried out properly.

1.2738 Quenching

Quenching material 1.2738 converts austenite back into martensite, a very brittle phase. 1.2738 should be tempered after quenching to relieve stresses and reduce brittleness.

- Polymer

- Oil

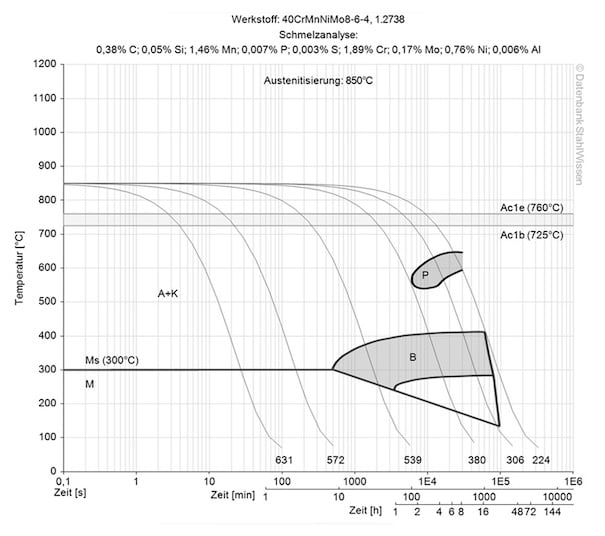

1.2738 Continuous TTT-diagram

This diagram shows micro-changes over time at different temperatures. These are important in heat treatment because they provide information about the optimal conditions for processes such as hardening, annealing and normalising.

1.2738 SURFACE TREATMENT

Please find below some examples of surface treatments for tool steel 1.2738.

1.2738 Nitriding

The 1.2738 material can be nitrided to increase surface hardness and resistance to wear and erosion. Nitriding the surface also increases corrosion resistance. To nitride the material, it should be pre-machined, stress-relieved and ground beforehand.

1.2738 Hard chrome plating

The material grade 1.2738 is suitable for chrome plating. After hard chrome plating, temper the material at a temperature of 180 °C for approx. 4 hours. To prevent hydrogen embrittlement, tempering should be carried out within 4 hours of the coating process.

1.2738 Polishing

1.2738 exhibits good polishability in its delivery condition (annealed). Care should be taken not to polish the workpieces too vigorously with high pressure, as excessive polishing can lead to undesirable damage such as discolouration, orange peel or pitting. It is also very important to prepare the workpiece properly. Tools and workpieces should be free of dust, and a polishing paste should be added to the tool during manual or machine polishing. If the material is not prepared to be dust-free, particles can penetrate the surface during polishing and cause pitting and/or scratches on the surface. Scratches and pitting can in turn be entry points for moisture, which can lead to corrosion over time.

1.2738 PROCESSING

1.2738 is easy to machine and produces an excellent surface finish. Cutting speed and feed rate should be adjusted to suit the hardness of the material, and coolant should be used to reduce overheating and tool wear.

1.2738 Machining allowance / dimensional changes

Rapid heating and cooling, stress relief annealing, machining and welding may cause dimensional changes. These processes should be carefully controlled and carried out evenly to avoid deformation.

1.2738 Welding

1.2738 can be welded using all conventional methods. Heat the material to a temperature of 316–371 °C, ensuring that the welding temperature does not fall below 316 °C. Fillers should be matched to the hardness of the base material. Allow to cool slowly to 100–150 °C. Then heat to a temperature of 538 °C for one hour per 25 mm of weld depth, without exceeding 566 °C, as this would lead to a loss of hardness. Afterwards, the material should be tempered twice if possible.