1.4034 - AT A GLANCE

What kind of steel is the 1.4034?

Stainless steel 1.4034 (X46Cr13) has, in its annealed condition, good ductility and can when hardened, reach a hardness of min. 50 HRC. As a martensitic stainless steel 1.4034 is optimized for its high hardness, while other properties are compromised to some degree. 1.4034 loses ductility at sub-zero temperatures and is in comparison to austenitic steels less corrosion resistant, has poor weldability and loses strength when over-tempered at elevated temperatures.

Properties

Considering the applications and properties the 1.4034 achieves good hardness, strength and wear resistance when hardened and has good corrosion resistance, even if it is at the lower end compared to other stainless steels. This makes it a good choice not only for knives, but also for cutting instruments, tools and decorative applications.

- Corrosion resistant cold work steel

- Plastic mold steel

- Martensite

- Good machinability

- Magnetizable

- Hardenable

- Polishable

- Low distortion through hardener

- High hardness acceptance

- Good wear resistance

- Poor weldability

Applications

Due to the combination of high hardness, corrosion resistance, wear resistance and polishability the 1.4034 stainless steel can be used for applications like razor blades, dental and surgical instruments, plastic molds, and machine, valve and firearm parts.

- Mechanical engineering

- Medical technology

- Plastic molds

- Synthetic resin mold tools

- Die casting tools

- Cutting tools

- Machine knives

- Scraper blades

- Surgical instruments

- Measuring tools

- Ice-skates

- Pump parts

- Valves

1.4034 Standard values

Chemical composition:

| C | Si | Mn | P | S | Cr |

|---|---|---|---|---|---|

| 0.43 - 0.5 | 0.0 - 1.0 | 0.0 - 1.0 | 0.0 - 0.04 | 0.0 - 0.015 | 12.5 - 14.5 |

Chemical designation:

X46Cr13

Working hardness:

50-55 HRC

Delivery condition:

max. 241 HB

1.4034 Physical properties

What group of steel does the 1.4034 belong to?

- Martensitic stainless steel

- Stainless steel corrosion resistant

- Stainless steel acid resistant

- Stainless steel

- Plastic mould steel

- Cold work steel

Is the 1.4034 a stainless steel?

Yes, the 1.4034 is a martensitic stainless steel with a mass fraction of 12,5 to 14,5 % of chromium which gives this steel grade its corrosion resistance.

Is the 1.4034 corrosion resistant?

Stainless steel 1.4034 has good resistance to water and steam. It has moderate resistance to corrosive, chloride-free environments and is not resistant to intergranular corrosion after welding or in the annealed state. If corrosion resistance is an issue, care should be taken to ensure that the material is not excessively tempered or used in an annealed state, but rather in a hardened state with a well-machined, smooth surface.

Is the 1.4034 magnetisable?

As a martensitic stainless steel, the 1.4034 has a ferromagnetic microstructure, which makes it magnetisable in its annealed and hardened condition. Steel 1.4034 is suitable for the magnetic clamping technology.

1.4034 Wear resistance

This stainless steel is rated a 4 for wear resistance on a scale where 1 is low and 6 is high.

1.4034 Temperature resistance

1.4034 should be used at moderately elevated temperatures. It is not recommended for use at temperatures above 430°C, as this reduces corrosion resistance and mechanical properties.

1.4034 Technical Properties

Is stainless steel 1.4034 a knife steel?

The 1.4034 can be used as a knife steel. It is easy to sharpen has good corrosion resistance and good toughness. One disadvantage is its lack of edge retention, which means that it needs to be sharpened more often.

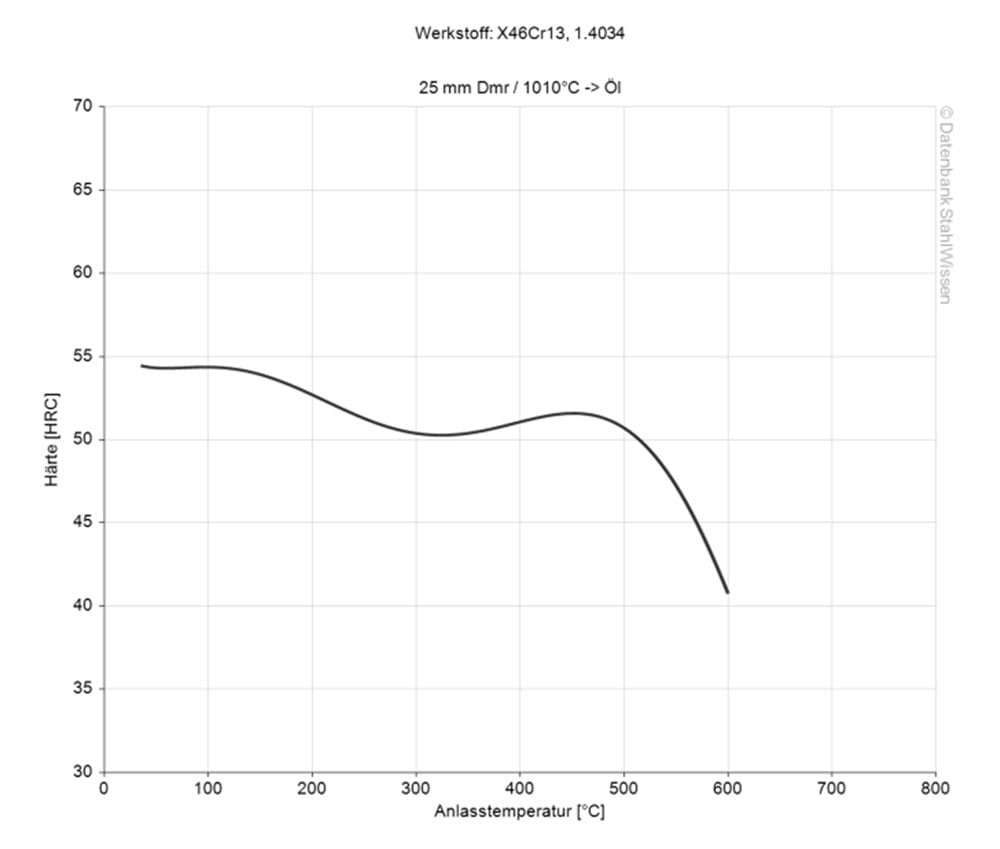

1.4034 Working hardness HRC

The working hardness for stainless steel 1.4034 is in the range of 50 – 55 HRC.

1.4034 Density

The typical density at room temperature for stainless steel 1.4034 is approx. 7,7 g/cm3.

1.4034 Tensile strength

The 1.4034 has a tensile strength of approx. 815 N/mm2. This value is the result of a tensile test that shows how much force is required before the material begins to stretch or deform before it breaks.

1.4034 Yield strength

The yield strength indicates how much stress can be exerted on a material before it undergoes plastic deformation. Beyond this point, it will not return to its original shape, even if the stress is removed. The material will deform permanently or break beyond this point.

The range for 1.4034 stainless steel is between 515 and 1380 N/mm2.

1.4034 machinability

Stainless steel 1.4034 can be machined in a similar way to some carbon-rich steels and produces tough, fibrous chips. When annealed, the material is easier to machine than when hardened.

On a scale of 1 (low) to 6 (high), DIN 1.4034 is rated 4 for machinability.

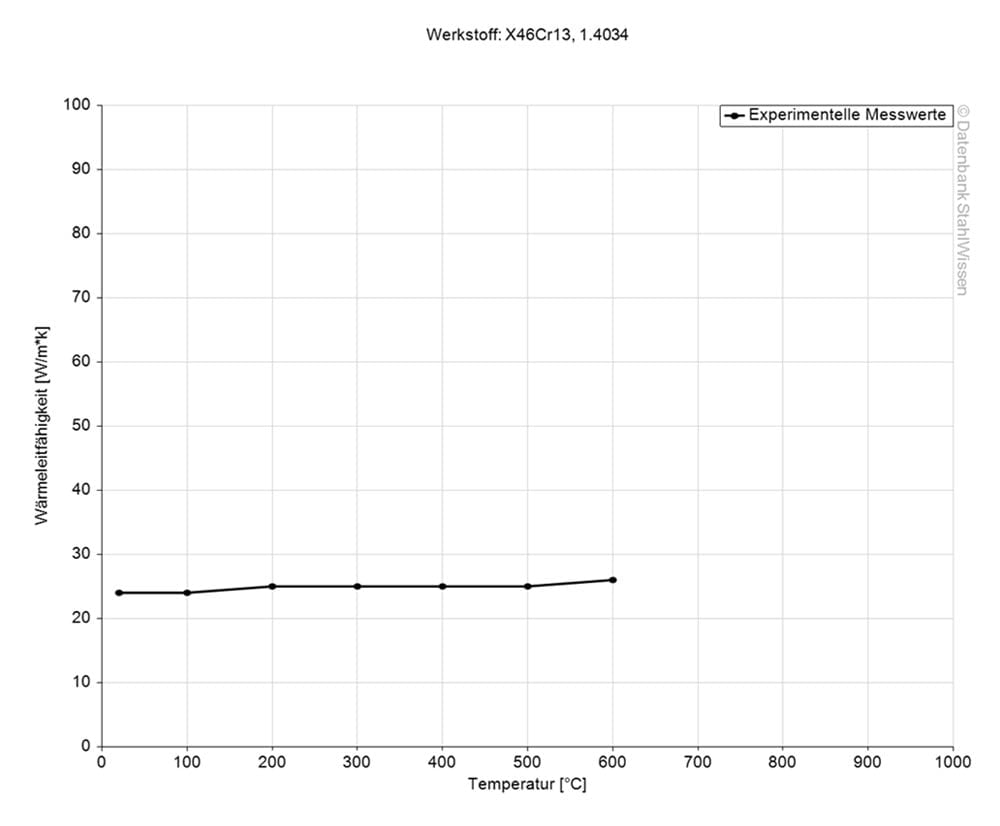

1.4034 Heat conductivity

The heat conductivity for stainless steel 1.4034 is 30 W/(m*K) at room temperature.

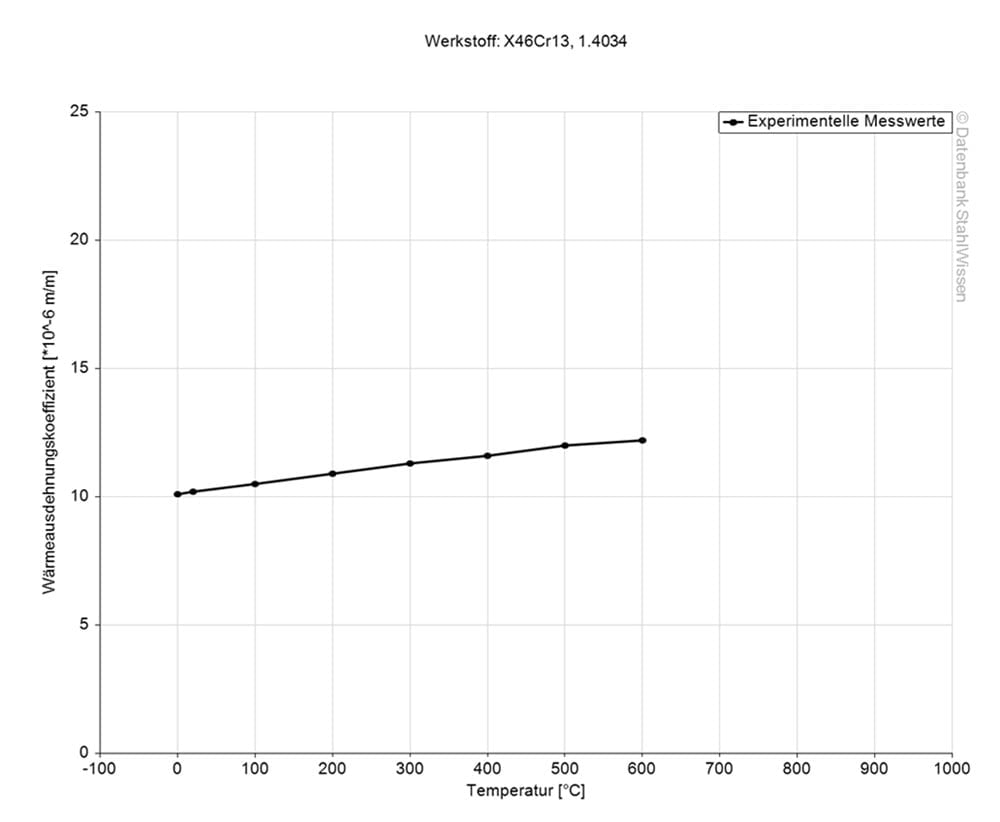

1.4034 Thermal expansion coefficient

The following table shows the expansion or contraction at different temperatures, which can be very important for work at high temperatures or with significant temperature fluctuations.

Medium thermal expansion coefficient

Value 10-6m/(m*K)

At a temperature of

10.5

20 – 100 °C

11.0

20 – 200 °C

11.5

20 – 300 °C

12.0

20 – 400 °C

12.0

20 – 500 °C

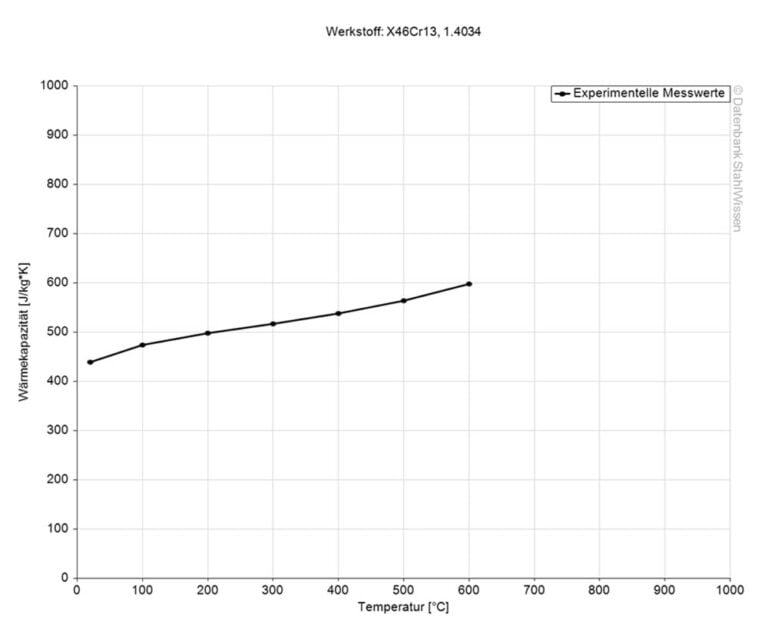

1.4034 Specific heat capacity

The specific heat capacity for stainless steel 1.4034 at room temperature is 0,46 J/kg*K. This value indicates how much heat is required to heat a certain amount of material by 1 Kelvin.

1.4034 Specific electrical resistance

The specific electrical resistance can be found in the following table. Electrical conductivity is the reciprocal of specific resistance.

Specific electrical resistance

Value (Ohm*mm2)/m

At a temperature of

0.55

20 °C

HART-PRÄZ® – ALREADY HARDENED DIMENSIONS IN LENGTH OF 250 mm AND 500 mm!

1.4034 Procedure

1.4034 Heat treatment

Heat treatment is used to determine material properties. It should therefore always be carried out with care. Properties such as strength, toughness, surface hardness and temperature resistance are determined, which in turn can extend/improve the service life of parts, tools and components.

Heat treatment includes solution annealing, soft annealing, normalising, stress relief annealing, but also tempering, hardening and quenching or tempering.

1.4034 Annealing

To anneal stainless steel 1.4034 heat the material to a temperature of 750 – 850 °C and hold it there. Afterwards let it cool down slowly in the furnace or in air.

1.4034 Stress relieving

Heat the material to a temperature of 150 – 430 °C and hold it there for 1 – 3 hours. The cool it in air or quench it in ol or water.

1.4034 Tempering

To achieve a wide range of hardness values and mechanical properties, heat the workpieces to a temperature range of 150–700 °C then cool them in still air. However, for optimum corrosion resistance and mechanical properties, the temperature range of 425–600 °C should be avoided.

Tempering this steel grade at low temperatures results in higher hardness, while higher temperatures improve toughness but reduce hardness.

Reduced notch toughness can be the result of temper brittleness, which can occur during tempering in the range of 425–600 °C.

1.4034 Hardening

Heat the material uniformly to a temperature range of 950 – 1050 °C and then cool it down fast in air or oil.

1.4034 Quenching

During quenching, 1.4034 stainless steel undergoes a phase transformation from austenite to martensite. Rapid cooling allows a higher hardness to be achieved. The faster the material is cooled, the more martensite is formed, whereas slow cooling may leave some austenite or other phases behind. However, rapid cooling also carries risks: it can generate stresses that lead to quenching cracks and can affect the toughness of the parts.

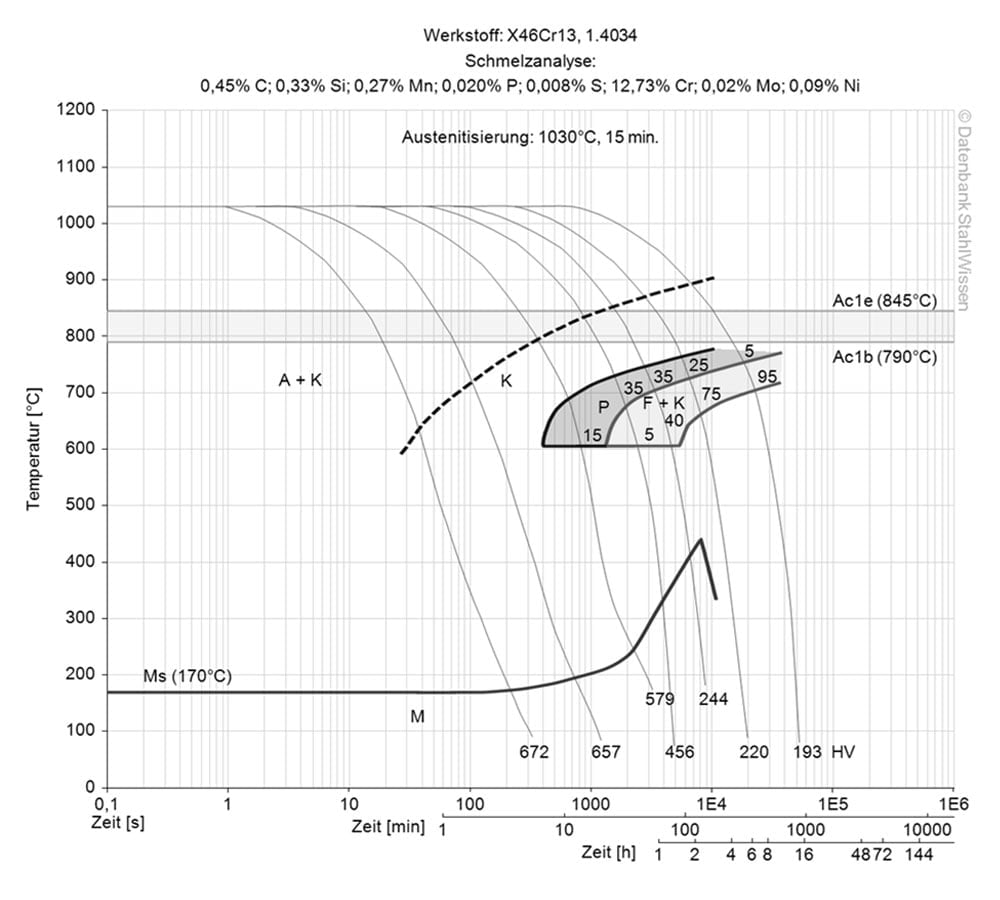

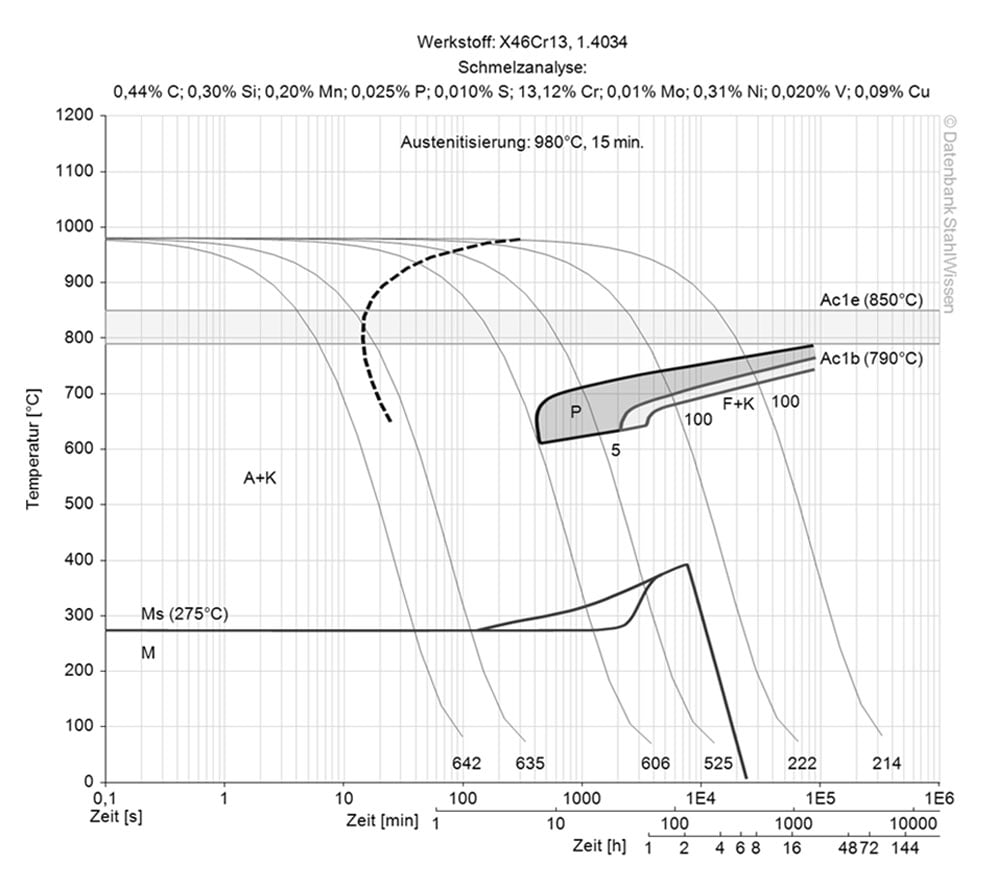

1.4034 Continuous TTT-Diagram

This diagram shows micro-changes over time at different temperatures. These are important in heat treatment because they provide information about the optimal conditions for processes such as hardening, annealing and normalising.

1.4034 Surface treatment

The choice of surface treatment depends on the requirements, the environment in which the workpieces/tools are used, the required properties and the expected loads. Below are a few examples of possible surface treatments.

1.4034 Nitriding

Like other surface treatments, nitriding can increase natural corrosion resistance by introducing nitrogen into the surface. This process can also improve wear resistance.

1.4034 Black oxide coating or blueing

This is a surface treatment that can improve corrosion resistance, but is often used for aesthetic reasons as it provides a black-blue finish that reduces light reflection from the surface.

1.4034 PVD and CVD coating

Both processes, PVD and CVD, apply a thin layer to the surface of the material. This thin, hard layer gives the material wear-resistant protection.

- PVD – physical vapour deposition

- CVD – chemical vapour deposition

1.4034 Passivation

This process removes free iron from the surface using nitric or citric acid and applies a protective oxide layer to the material.

1.4034 Polishing

Polishing the surface to a high gloss finish can improve the corrosion resistance, a smooth surface can minimise the adhesion of contaminants.

1.4034 Electropolishing

Electropolishing is a non-mechanical chemical process in which a thin layer of material is removed using an electric current to give the material a smooth and shiny surface and minimise the adhesion of bacteria, which can be beneficial in medical devices and/or food processing equipment.

1.4034 Shot blasting

During this process, multiple high-speed shots are fired at the surface of the material, leaving small indentations to eliminate stress peaks. This makes the surface more resistant and can prevent fatigue and stress corrosion damage.

1.4034 Bead blasting

Abrasive particles such as glass or ceramic beads are blasted onto the surface to remove contaminants such as rust, paint or scale and achieve a uniform matt finish.

1.4034 Processing

1.4034 Electrical Discharge Machining (EDM)

Eroding can be used to achieve various surface finishes, but it is mainly used to produce complicated shapes, small details and complex geometries in hard materials. As the material 1.4034 is in the upper hardness range, eroding can be used successfully. When selecting the electrodes, dielectric fluid and cutting speed, the surface quality and subsequent application should be taken into account.

1.4034 Dimensional changes

The conversion of austenite to martensite may cause slight shrinkage, which can affect the dimensions of the parts, and the residual austenite may further influence the dimensions during tempering.

1.4034 Forging

Heat the workpiece slowly to a temperature of about 800 °C, then more quickly to 1050 – 1140 °C. Forging should be carried out in the temperature range of 1100 – 800 °C, then slowly cooled in the furnace with dry ash or other materials that allow slow cooling.

Although forging has some advantages, such as grain refinement, elimination of porosity, better directional strength and an improved structure, to name but a few, it also has a few disadvantages. Forging can cause high tool wear, especially in the hardened state, form a layer of scale that must be removed after forging, and possibly require heat treatment after forging. Compared to casting, machining or eroding, forging is limited to coarser shapes.

1.4034 Welding

As this is an air-hardening steel, 1.4034 stainless steel is rarely welded.

If welding cannot be avoided, it should be preheated to 149–204 °C before welding and then annealed for 6–8 hours at a temperature of 732–788 °C, followed by air cooling. To maintain its mechanical properties, the filler material, where necessary, should be similar to the base material.