1.4057 - ATA GLANCE

What kind of steel is the 1.4057?

The added chromium and nickel alloys, givesvthe 1.4057 (X17CrNi16-2) a better toughness as well as better corrosion resistance compared to straight up chromium stainless steels. This makes this steel grade ideal for operations like deep drawing, compressor parts and construction. This steel grade is also often used in processing chemically aggressive plastics, like PVC for instance.

Properties

As with all material choices, applications and properties should be considered when choosing a steel. The 1.4057 offers good corrosion resistance in mild to moderate corrosive environments but is susceptible to pitting when exposed to chloride rich environments. It has high tensile strength, good machinability and can achieve mechanical properties like hardness or toughness by heat treating this material.

- Martensitic chromium steel

- High strength in as-delivered condition (quenched and tempered)

- Very good corrosion resistance

- High toughness

- High tensile strength

- Good machinability

- Good weldability

- Magnetizable

- Limited acid resistance

- Forgeable

Applications

Due to its tensile strength and corrosion resistance 1.4057 can be used for fasteners like bolts and screws or mechanical components like shafts and axles. Furthermore it can be used for pumps and valve components, aircraft components like landing gear or pivot pins.

Automotive parts like engine components and exhaust system parts or in the food processing industry as it can withstand harsher cleaning processes. With its sharpness and corrosion resistance the 1.4057 lends itself for cutlery and surgical instruments.

- Mechanical engineering

- Automotive industry

- Oil and petrochemical industry

- Aviation

- Food industry

- Soap industry

- Acetic acid industry

- Shafts

- Pump parts

- Perforated plates

- Spindles

- Piston rods

- Valve cones

- Turbine blades

1.4057 STANDARD VALUES

Chemical composition:

| C | Si | Mn | P | S | Cr | Ni |

|---|---|---|---|---|---|---|

| 0.12 - 0.22 | 0.0 - 1.0 | 0 - 1.5 | 0.0 - 0.04 | 0.0 - 0.03 | 15.0 - 17.0 | 1.5 - 2.5 |

Chemical designation:

X17CrNi16-2

Working hardness:

approx. 32 HRC (approx. on delivery) to 47 HRC

Delivery condition:

max. 331 HB

1.4057 Physical properties

What group of steel does the 1.4057 belong to?

- Martensitic chromium steel

- Stainless steel, corrosion resistant

- Stainless steel, acid resistant

- Stainless steel

- Cold work steel

- Hot work steel

Is the 1.4057 a stainless steel?

Yes, 1.4057 is a stainless steel as it has a mass fraction of 15 – 17 % of chromium.

Is the 1.4057 corrosion resistant?

A corrosion resistant steel has at least 10,5 % of chromium, with a mass fraction of 15 – 17 % of chromium the 1.4057 as a classich stainless steel is corrosion resistant.

1.4057 General corrosion resistance

1.4057 offers corrosion resistance in mild atmospheric environments with exposure to moisture. In seawater, pitting may occur at temperatures from 20 °C.

Is the 1.4057 magnetisable?

As a martensitic stainless steel, 1.4057 can be magnetised and can be used for applications where this is desired or required. For processing, it can be placed on a magnetic clamping plate.

1.4057 Wear resistance

On a scale of 1 to 6, where 1 is low and 6 is high, the 1.4057 receives a 3 for its wear resistance.

1.4057 Technical properties

Is the 1.4057 a knife steel?

The 1.4057 can be used as a kinfe steel and offers good corrosion resistance. That said there are other stainless steels which lend them selfs better due to their higher toughness and that are easier to sharpen as well as keeping their edge longer.

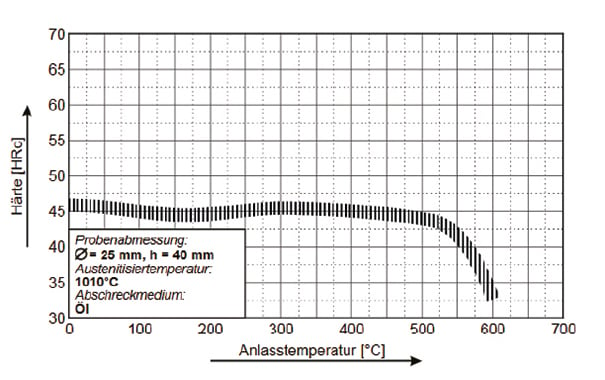

1.4057 Working hardness

The working hardness for the 1.4057 is at approx. 32 – 47 HRC.

1.4057 Density

Typically the density for the 1.4057 at room temperature is at 7,7 g/cm3.

1.4057 Tensile strength

The 1.4057 has a tensile strength of approx. 1050 N/mm2. This value is the result of a tensile test that shows how much force is required before the material begins to stretch or deform before it breaks.

1.4057 Yield strength

The yield strength indicates how much stress can be exerted on a material before it undergoes plastic deformation. Beyond this point, it will not return to its original shape, even if the stress is removed. The material will deform permanently or break beyond this point.

The range for 1.4057 stainless steel is between 515 N/mm2.

1.4057 Heat resistance

Due to the loss of its mechanical properties the 1.4057 should not be used above its standard tempering temperatures. When used intermittently at 925 °C and continuously at a temperature of 870 °C, this steel grade is resistant to scale.

1.4057 Machinability

On a scale where 1 is low and 6 is high the 1.4057 receives a 3 for its machinability.

1.4057 Heat conductivity

At room temperature the heat conductivity for this material is at ~25 W/(m*K).

1.4057 Thermal expansion coefficient

The following table shows the expansion or contraction at different temperatures, which can be very important for work at high temperatures or with significant temperature fluctuations.

Medium thermal expansion coefficient

Value 10-6m/(m*K)

At a temperature of

10.0

20 – 100 °C

10.5

20 – 200 °C

10.5

20 – 300 °C

10.6

20 – 400 °C

11.0

20 – 500 °C

1.4057 Specific heat capacity

The specific heat capacity for stainless steel 1.4057 at room temperature is 0,46 J/kg*K. This value indicates how much heat is required to heat a certain amount of material by 1 Kelvin.

1.4057 Specific electrical resistance

The specific electrical resistance can be found in the following table. Electrical conductivity is the reciprocal of specific resistance.

Specific electrical resistance

Value (Ohm*mm2)/m

At a temperature of

~0.7

~ 20 °C

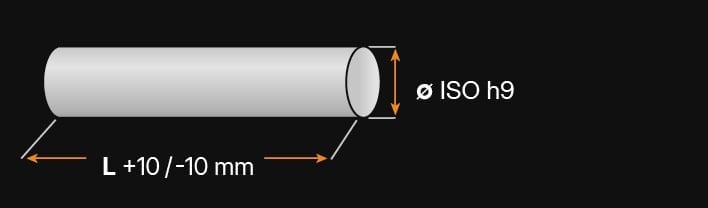

PRECISION ROUND STEEL WITHOUT MACHINING ALLOWANCE – ISO h9

1.4057 Procedure

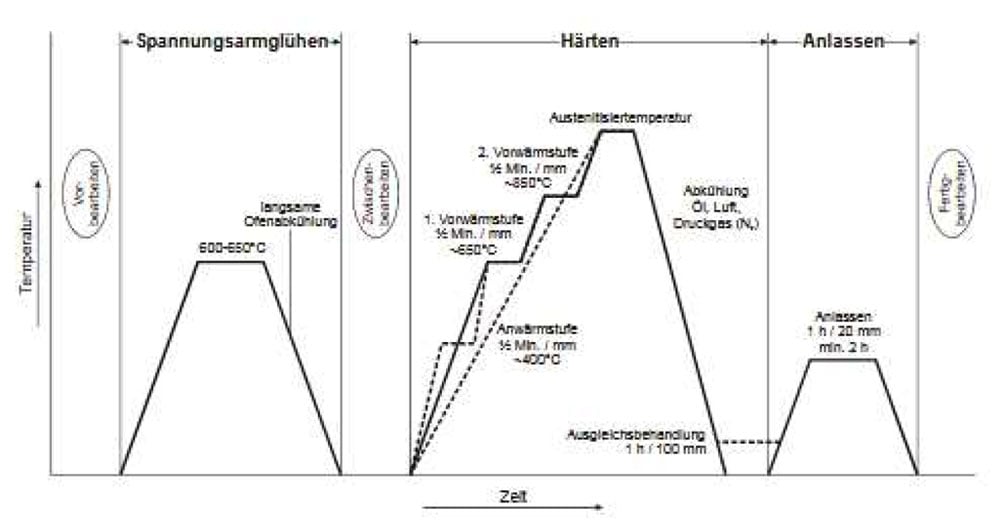

1.4057 Heat treatment

The desired properties determine the temperatures, holding times and cooling rates during the heat treatment of the 1.4057.

1.4057 Annealing

Heat the workpieces to a temperature range of 680 – 800 °C and hold there. Afterwards cool them slowly and controlled in the furnace.

1.4057 Tempering

To reduce brittleness and improve the toughness for the 1.4057 tempering is a very important step in the heat treatment process.

Heat the material evenly to a temperature of 600 – 650 °C and hold for at leat an hour, then cool it in air.

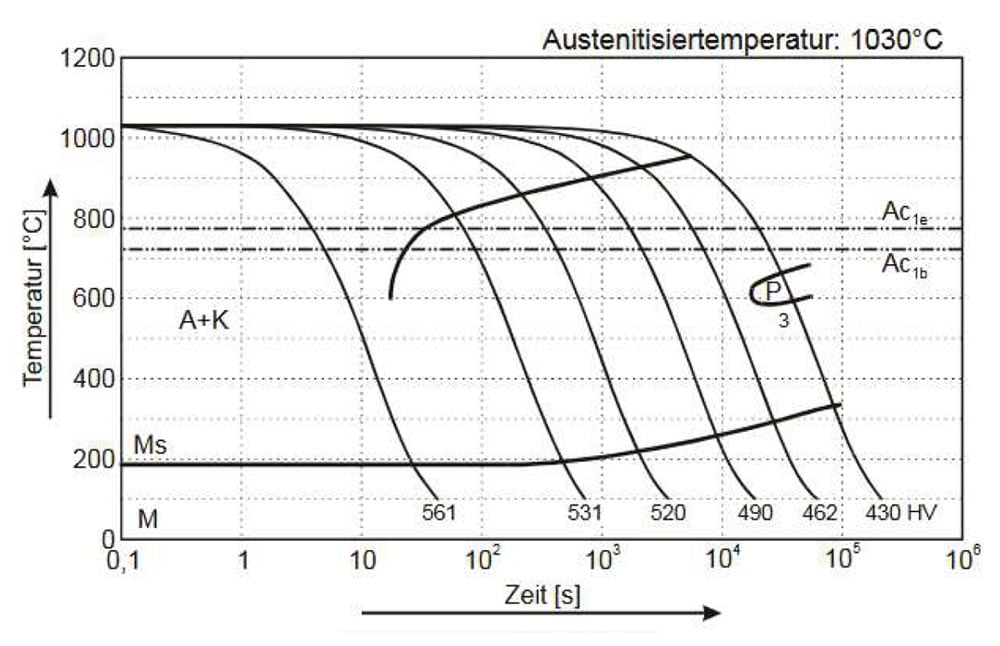

1.4057 Austenitisation

Heat the material to a temperature range of 950 – 1050 °C and hold at that temperature until the whole structure has changed to austenite. The cooling can be done in oil or air. This material grades tends to harden in air when cooling.

1.4057 Quenching

Quenching the 1.4057 can be done in oil, water or air which changes austenit quickly to a hard and brittle martensistic structure. Its properties are determined by the choice of quenching medium.

- Oil

- Air

- Water

1.4057 Continuous TTT-Diagram

This diagram shows micro-changes over time at different temperatures. These are important in heat treatment because they provide information about the optimal conditions for processes such as hardening, annealing and normalising.

1.4057 Surface treatment

1.4057 Nitriding

While nitriding nitrogen is diffused into the material surface which give the 1.4057 a hard surface for better wear resistance.

1.4057 Black oxide coating or blueing

This is a surface treatment that can improve corrosion resistance, but is often used for aesthetic reasons as it provides a black-blue finish that reduces light reflection from the surface.

1.4057 PVD and CVD coating

Both PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition) coatings apply a thin layer to the material surface that can increase wear resistance or reduce friction.

- PVD – physical vapor deposition

- CVD – chemical vapor deposition

1.4057 Passivation

This process removes free iron from the surface using nitric or citric acid and applies a protective oxide layer to the material that can prevent rust and other forms of corrosion when this material is exposed to a corrosive environment.

1.4057 Beat blasting

Abrasive particles such as glass or ceramic beads are blasted against the surface to remove contaminants such as rust, paint or scale and achieve a uniform matt finish. It makes the surface more resistant and can prevent fatigue and stress corrosion damage.

1.4057 Electro polishing

Electropolishing is a non-mechanical chemical process in which a thin layer of material is removed using an electric current to give the material a smooth and shiny surface and minimise the adhesion of bacteria, which can be beneficial in medical devices and/or food processing equipment.

1.4057 Processing

Annealed this material is somewhat easy to machine. In its hardened condition, over 30 HRC, it is difficult to machine.

1.4057 Electrical Discharge Machining (EDM)

1.4057 can be eroded. However, the condition (annealed or hardened) in which it is eroded should be taken into account. When hardened, erosion can be more challenging and machining parameters and special electrodes should be considered. Therefore, erosion of 1.4057 should be carefully planned and controlled.

1.4057 Machining allowance / dimensional changes

Dimensional changes may occur when steel undergoes phase changes during heat treatment or cooling.

During austenitisation, 1.4057 material may expand when heated. During tempering, internal stresses are redistributed, which may cause the material to expand slightly, but not as much as during austenitisation. On the other hand, cooling 1.4057 by quenching, the phase change from austenite to martensite, can reduce the dimensions due to contraction. Excessive contraction of the material can lead to deformation or cracks if the process is not properly controlled.

1.4057 Forging

Heat the workpieces slowly and carefully to a temperature of 850 °C and elevate the temperature then quickly to 1150 – 1180 °C. The forging temperature is between 1180 – 950 °C. When finished with forging the material should be cooled down slowly in the furnace, dry ash or another material which allows a slow cooling process.

1.4057 Welding

With careful preparation the 1.4057 can be welded. Preheat the material to a temperatur of 100 – 300 °C. Welding temperatures under 200 °C should be avoided. After welding let the material cool down until it reaches an ambient temperature, then heat it for a heat treatment to 650 °C. Without the additional post heat treatment properties in the heat affected zones can be very different to the rest of the material. To prevent contamination, welding with hydrogen or nitrogen-containing gases should be avoided, which also have a negative effect on the mechanical properties. To ensure the best possible corrosion resistance in the weld seam, discolouration must be removed either mechanically or chemically.