1.4104 - AT A GLANCE

What kind of steel is the 1.4104?

In comparison with other martensitic stainless steels containing 17% of chromium the 1.4104 has a lower corrosion resistance due to the added sulphur.

The added sulphur gives 1.4104 stainless steel an excellent machinability, with a fine ground surface finish which can be used for construction parts for applications in water and steam. Due to its corrosion resistance and appearance this steel grade is often used for decorative applications and kitchen fittings.

Properties

The balance of corrosion resistance, machinability, mechanical properties and aesthetics make 1.4104 a good choice to manufacture fasteners, gears, architectural ornamental elements and household appliances.

- Martensitic chromium steel (here quenched and tempered version)

- Addition of sulphur for improved machining

- Very good polishability

- Conditionally acid-resistant

- Magnetizable

- Welding not commonly done

Applications

Stainless steel 1.4104 can be used for bolts, fasteners, screws, shafts, valves, injector parts and kitchen utensils to name just a few. Due to the added Sulphur it can be easily machined, is corrosion resistant and can maintain an aesthetic finish with the correct care.

- Automotive industry

- Electronic equipment

- Power engineering

- Mechanical engineering

- Connecting elements

- Architecture and decoration

- Construction parts for automatic machining in water and steam, for example screws, spindles, axles, bushes etc.

1.4104 STANDARD VALUES

Chemical composition:

| C | Si | Mn | P | S | Cr | Mo |

|---|---|---|---|---|---|---|

| 0.10 - 0.17 | 0.0 - 1.0 | 0.0 - 1.5 | 0.0 - 0.04 | 0.15 - 0.35 | 15.5 - 17.5 | 0.20 - 0.60 |

Chemical designation:

X14CrMoS17

Working hardness:

ca. 26 HRC (Richtwert des Lieferzustand)

Delivery condition:

max. 270 HB

1.4104 Physical properties

What group of steel does the 1.4104 belong to?

- Martensitic stainless steel

- Stainless steel, corrosion resistant

- Stainless steel, acid resistant

- Stainless steel

- Chromium steel

Is the 1.4104 a stainless steel?

Yes, with a mass fraction of 15,5 – 17,5 % of chromium the 1.4104 is a stainless steel. To be classified as stainless steel a steel grade has to have a mass fraction of at leat 10,5 %.

Is the 1.4104 corrosion resistant?

From a chromium content of 10,5 % a steel is corrosion resistant. With a chromium content of 15,5 – 17,5 % the 1.4104 can beclassified as corrosion resistant.

1.4104 General corrosion resistance

Due to the added sulphur, 1.4104 has a moderate corrosion resistance, which makes it difficult to use this steel in environments where pitting or crevice corrosion can be a problem.

Is the 1.4104 magnetisable?

As a ferro magnetic steel the 1.4104 is magnetisable which can be an advatage for various processes. This stainless steel is suitable for magnetic clamping technology.

1.4104 Wear resistance

On a scale where 1 is low and 6 is high the 1.4104 receives a 3 for its wear resistance.

1.4104 Technical properties

Is the 1.4104 a knife steel?

1.4104 can be used as knife steel. As one of the softer stainless steels, it is easier to sharpen than others, but does not remain as sharp as a harder stainless steel. It has moderate corrosion resistance and toughness, which can cause 1.4104 to chip or break. This makes it a possible steel for cutlery knives, but it is not suitable as a blade for knives with higher performance requirements.

1.4104 Working hardness

The working hardness on delivery for the 1.4104 is apporox. 26 HRC.

1.4104 Density

Typically the density for the 1.4104 at room temperature is at 7,7 g/cm3.

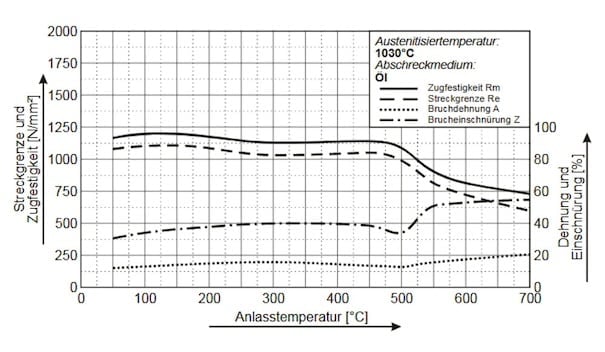

1.4104 Tensile strength

The 1.4057 has a tensile strength of approx. 1050 N/mm2. This value is the result of a tensile test that shows how much force is required before the material begins to stretch or deform before it breaks.

1.4104 Heat conductivity

At room temperature, the thermal conductivity of 1.4104 is at 25.0 W/(m*K).

1.4104 Thermal expansion coefficient

The following table shows the expansion or contraction at different temperatures, which can be very important for work at high temperatures or with significant temperature fluctuations.

Medium thermal expansion coefficient

Value 10-6m/(m*K)

At a temperature of

10.0

20 – 100 °C

10.5

20 – 200 °C

10.5

20 – 300 °C

10.5

20 – 400 °C

1.4104 Specific heat capacity

The specific heat capacity for stainless steel 1.4104 at room temperature is 0,46 J/kg*K. This value indicates how much heat is required to heat a certain amount of material by 1 Kelvin.

1.4104 Specific electrical resistance

The specific electrical resistance can be found in the following table. Electrical conductivity is the reciprocal of specific resistance.

Specific electrical resistance

Value (Ohm*mm2)/m

At a temperature of

0.70

20 °C

BECOME EVEN BETTER WITH ABRAMS PREMIUM STEEL® THAN YOUR COMPETITORS SUSPECT!

1.4104 Procedure

1.4104 Heat treatment

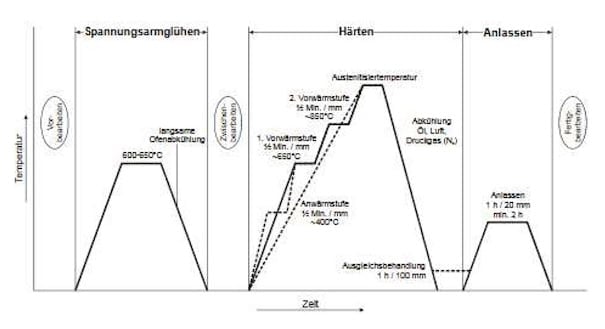

Heat treatment is used to determine material properties. It should therefore always be carried out with care. Properties such as strength, toughness, surface hardness and temperature resistance are determined, which in turn can extend/improve the service life of parts, tools and components.

Heat treatment includes solution annealing, soft annealing, normalising, stress relief annealing, but also tempering, hardening and quenching or tempering.

1.4104 Annealing

To anneal the 1.4104, heat the material to a temperature of 750–850 °C and complete the process by cooling the workpieces in the furnace or in air.

1.4104 Tempering

Heat the parts evenly to a temperature of 550–650 °C and then allow them to cool in the air. The temperature for the tempering process depends on the desired strength.

1.4104 Hardening

Heat the workpieces evenly to a temperature of 950 – 1070 °C and quench to finish this process.

1.4104 Quenching

The 1.4104 can be quenched in the following media:

- Air

- Oil

- Compressed gas (N2)

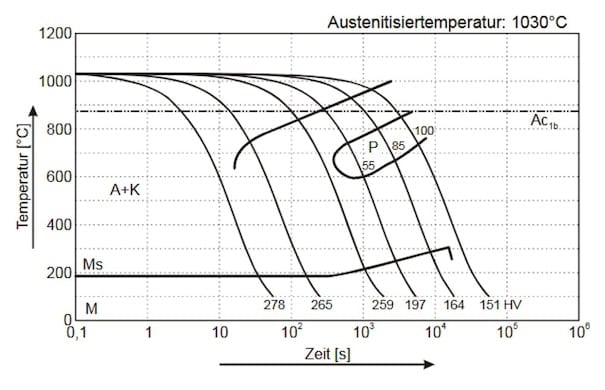

1.4104 Continuous TTT-Diagram

This diagram shows micro-changes over time at different temperatures. These are important in heat treatment because they provide information about the optimal conditions for processes such as hardening, annealing and normalising.

1.4104 Surface treatment

1.4104 Passivation

This process removes free iron from the surface using nitric or citric acid and applies a protective oxide layer to the material that can prevent rust and other forms of corrosion when this material is exposed to a corrosive environment.

1.4104 PVD and CVD coating

Both PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition) coatings apply a thin layer to the material surface that can increase wear resistance or reduce friction.

- PVD – physical vapor deposition

- CVD – chemical vapor deposition

1.4104 Bead blasting

Abrasive particles such as glass or ceramic beads are blasted against the surface to remove contaminants such as rust, paint or scale and achieve a uniform matt finish. It makes the surface more resistant and can prevent fatigue and stress corrosion damage.

1.4104 Pickling

Caution is advised with this process, as sulphur is contained in the 1.4104 to improve the machinability of the material. Pickling is a chemical treatment with strong acids. Therefore, care must be taken to avoid excessive etching and pitting on the surface.

1.4104 Process

The addition of sulphur makes this stainless steel easier to machine than other steels with 12 and 17% chromium.

1.4104 Electrical Discharge Machining (EDM)

Eroding can be used to achieve various surface finishes, but it is mainly used to produce complicated shapes, small details and complex geometries in hard materials. When selecting the electrodes, dielectric fluid and cutting speed, the surface quality and subsequent application should be taken into account. Care should also be taken to minimise the areas affected by heat and to use the correct parameters when removing material.

1.4104 Maching allowance / dimensional changes

During heat treatment, the 1.4104 may undergo dimensional changes due to phase changes, machining and internal stresses. Overheating, uneven heating or cooling should be avoided. Controlled heating and cooling, as well as proper machining with sharp tools, coolants and appropriate feed rates can prevent heat build-up and thermal shock.

1.4104 Forging

Heat the material evenly to a temperature of 815 – 870 °C and the quickly to the forging temperature which is between 800 – 110 °C. Do not let the temperature drop below 815 °C and do not allow the workpiece to soak at forging temperature, as this can lead to grain formation. To finish off this process let the forgings cool down in air and anneal them after.

1.4104 Welding

Generally this steel grade does not get welded due to the added sulphur.

Should welding be unavoidable the material should be preheated to a temperature of 150 – 200 °C.

Brittleness in the weld material and in the heat-affected zone can be reduced by subsequent post-annealing of the parts at a temperature of 790 – 815 °C, but this does not result in any refinement of the structure. Filler materials and electrodes should be chosen according to the application of the workpieces.