1.4305 - AT A GLANCE

What kind of steel is the 1.4305?

As with other austenitic stainless steels the 1.4305 has good toughness and is non-magnetic. Added sulphur makes this steel better machinable but affects the corrosion resistance and lowers the toughness of this grade slightly.

Apart from better machining the added sulphur helps break chips into smaller, more manageable pieces, contributes to a smoother and more consistent finish and can extend tool life.

Properties

Stainless steel 1.4305 is chosen when machinability is the focus. Its good machinability enables the production of high precision components which are often used in the automotive or electronics industry. Though it has a lower corrosion resistance than some other stainless steels, it is resistant to atmospheric corrosion and mild chemical exposure.

- Austenitic chromium-nickel steel

- Free-cutting steel

- Corrosion resistant

- Non-magnetic

- Very good machinability

- Limited polishability

- Poor polishability

- Poor weldability

- Limited acid resistance

Applications

Due to its good machinability this steel grade is used for applications that require parts to be easily machined: shafts, springs bushings, nuts and bolts, valves, components in the automotive industry as well as in the machining industry.

- Food industry

- Photographic industry

- Paint industry

- Oil industry

- Soap industry

- Paper industry

- Textile industry

- Mechanical engineering

- Turned parts

- Fittings construction

- Kitchen equipment

- Decoration

1.4305 Standard values

Chemical composition:

| C | Si | Mn | P | S | Cr | Ni | Cu | N |

|---|---|---|---|---|---|---|---|---|

| 0.0 - 0.1 | 0.0 - 1.0 | 0.0 - 2.0 | 0.0 - 0.045 | 0.15 - 0.35 | 17.0 - 19.0 | 8.0 - 10.0 | 0.0 - 1.0 | 0.0 - 0.11 |

Chemical designation:

X8CrNiS18-9

Working hardness:

215-250 HB (delivery condition)

Delivery condition:

max. 250 HB

1.4305 Physical properties

What group of steel does the 1.4305 belong to?

- Austenitic stainless steel

- Stainless steel, corrosion resistant

- Stainless steel, acid resistant

- Stainless steel

- Free-cutting steel

- V2A

Is the 1.4305 a stainless steel?

With a mass fraction of 17 – 19 % of chromium the 1.4305 is a stainless steel.

Is the 1.4305 corrosion resistant?

The 1.4305 is due to its mass fraction of 17 – 19 % of chromium corrosion resistant. In addition it mass fraction of 8 – 10 % of nickel can improve its corrosion resistance even more.

1.4305 General corrosion resistance

Sulphur makes this grade susceptible to pitting corrosion, so it should not be used in chloride-containing environments above 60 °C. This steel grade is better suited for use in mild conditions. In humid environments, such as in marine applications, both pitting and a layer of rust form. For even higher corrosion resistance, a steel with a higher chromium and nickel content should be used.

Is stainless steel 1.4305 magnetisable?

In general, 1.4305 is not magnetic in its annealed state. However, cold working of this material grade can change the microstructure in such a way that it becomes partially or completely magnetic. Annealing the material reverses the process and returns the material to its non-magnetic state.

1.4305 Hot work

Heat the matrial 1.4305 evenly to a temperature of 1150 – 1260 °C for hot forming it and then cool it done quickly to assure the maximum corrosion resistance.

1.4305 Cold work

Stainless steel 1.4305 cannot be cold worked without further treatment. Some cold working is possible, but no severe working should be carried out.

1.4305 Wear resistance

This stainless steel receives a 2 for its wear resistance on a scale where 1 is low and 6 is high.

1.4305 Temperature resistance

Stainless steel 1.4305 exhibits good oxidation resistance when the material is sporadically exposed to temperatures of 760 °C, but also in continuous operation at 870 °C. The latter is not recommended, as this steel grade is susceptible to carbide precipitation when used continuously in a temperature range of 425–860 °C.

1.4305 Technical properties

Is stainless steel 1.4305 a knife steel?

The 1.4305 is a classical knife steel as it has the right balance between hardness and toughness for a good cutting edge, sharpness and chipping resistance.

1.4305 Working hardness

The working hardness for stainless steel 1.4305 is at max. 20 HRC.

1.4303 Density

At room temperature the density for the 1.4305 is at 7,9 g/cm3.

1.4305 Tensile strength

1.4305 has a tensile strength of approx. 800 N/mm2. This value is the result of a tensile test that shows how much force is required before the material begins to stretch or deform before it breaks.

1.4305 Machinability

To avoid excessive work hardening, the cutting edges must be sharp. Lubricants and coolants should be used generously to prevent heat build-up at the cutting edges, and chip breakers should be used to keep the workpiece free.

On a scale where 1 is low and 6 is high, 1.4305 receives a 6 for its machinability.

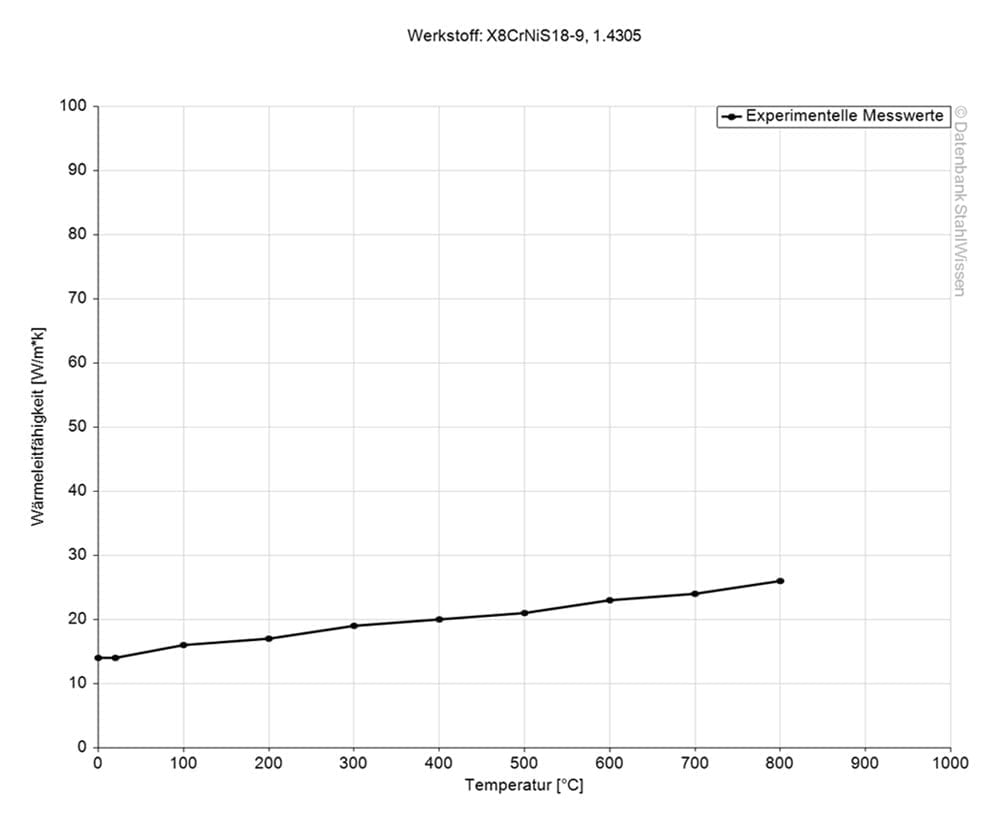

1.4305 Heat conductivity

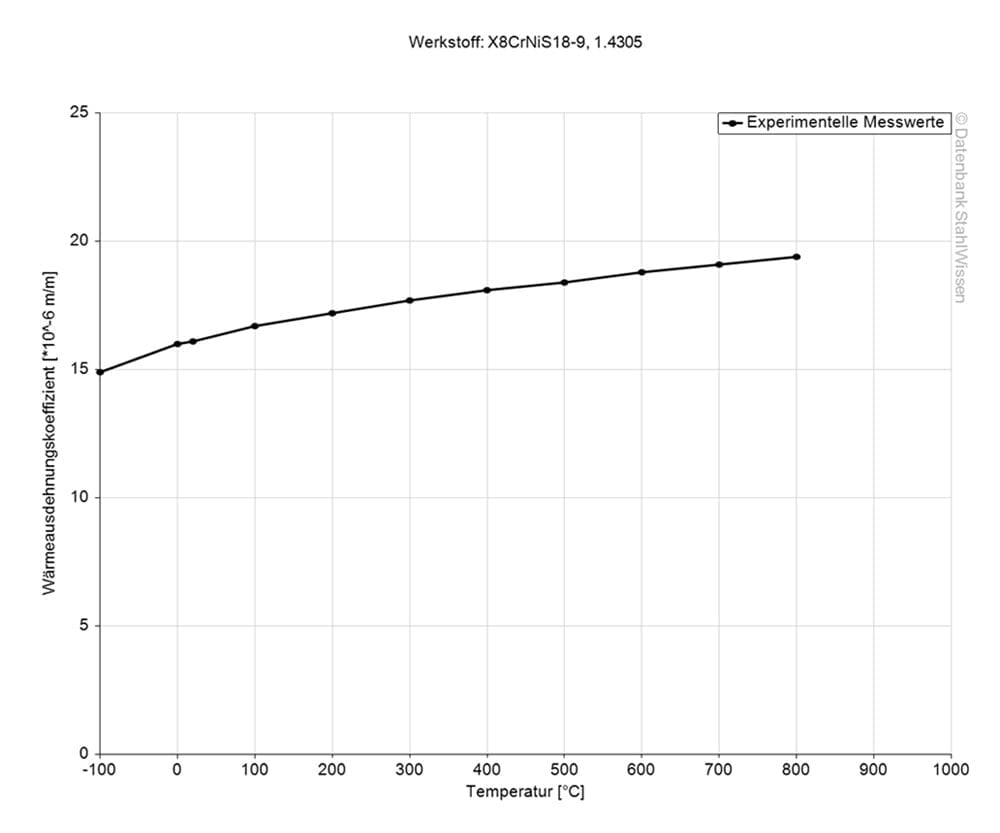

1.4305 Thermal expansion coefficient

The following table shows the expansion or contraction at different temperatures, which can be very important for work at high temperatures or with significant temperature fluctuations.

Medium thermal expansion coefficient

Value 10-6m/(m*K)

At a temperature of

16.0

20 – 100 °C

16.5

20 – 200 °C

17.0

20 – 300 °C

17.5

20 – 400 °C

18.0

20 – 500 °C

18.5

20 – 600 °C

18.5

20 – 700 °C

19.0

20 – 800 °C

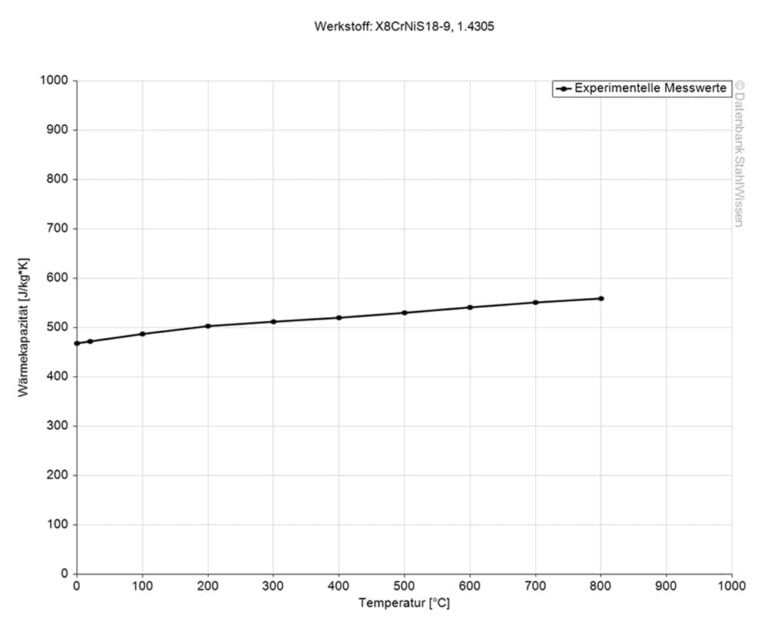

1.4305 Specific heat capacity

The specific heat capacity for stainless steel 1.4305 at room temperature is 0,5 J/kg*K. This value indicates how much heat is required to heat a certain amount of material by 1 Kelvin.

1.4305 Specific electrical resistance

The specific electrical resistance can be found in the following table. Electrical conductivity is the reciprocal of specific resistance.

Specific electrical resistance

Value (Ohm*mm2)/m

At a temperature of

~0.73

20 °C

FASTEST POSSIBLE DELIVERY!

1.4305 Procedure

1.4305 Heat treatment

The 1.4305 is not hardenable by heat treatment. Hardness and tensile strength can be improved by cold forming this material grade.

1.4305 Solution annealing

For this process the 1.4305 is heated up to a temperature of 1000 – 1100 °C and finished of with a cool down in air. Workpieces with a thickness of more than 2 mm can be quenched in water.

1.4305 Hardening

This steel grade cannot be hardened by a heat treatment but by cold forming it. This improves the hardness and strength of this material as the cystaline structure of this material is being deformed.

1.4305 Surface treatment

A surface treatment can optimise some properties. here are some examples:

1.4305 Nitriding

In general, it is possible to nitride austenitic steels, but this is considered very difficult and should be done in its annealed state. In the hardened condition, nitriding can cause blistering and impair corrosion resistance. A very thin nitride layer is achieved, and this grade should only be nitrided as an exception.

1.4305 Passivation

Passivation involves removing free iron from the surface by treating it with an acid solution, such as citric or nitric acid. Passivation creates a protective oxide layer that increases the corrosion resistance of this material.

1.4305 Electro polishing

During this process an electric current is used to remove a very thin layer of material which leaves a smooth and shiny surface. This is a non-mechanical process and is not to be confused with passivation which does not use an electric current.

1.4305 Ceramnic coating

Ceramic coating will create a hydrophobic layer which repels water and other contaminants which might damage the surface. It enhances the wear resistance and provides thermal insulation which is an advantage in high temperature and abrasive environments.

1.4305 Chemical colouring

Different colors can be achieved by chemically coloring the 303, depending on the thickness of the oxide layer, colors range from bronze, the thinnest oxide layer, to green, the thickest layer. The color sequence is bronze, blue, black, charcoal, gold, purple and green. As this is a chemically induced coloring it does not flake or peel when the material is formed or drawn for example. The colour intensity produced by the passive layer depends on the surface of the base material. If the base material has a matt surface, the passive layer will also appear matt; if the surface has been highly polished, the colour layer will also produce bright colours.

The oxide layer is harder which makes it more pitting resistant and does repel water and dirt.

1.4305 Processing

1.4305 Electrical Discharge Machining (EDM)

With the right choice of electrodes, dielectric and processing parameters, 1.4305 stainless steel can be eroded, enabling the machining of complex and complicated shapes with tight tolerances. Since erosion is a non-contact machining process, very little heat is generated, which is another advantage for 1.4305, as the properties of this grade are not affected.

1.4305 Dimentional changes

Like other materials, stainless steel 1.4305 can change its dimensions when heated or cooled. Under constant stress at higher temperatures, 1.4305 can creep, a slow and time-dependent deformation.

1.4305 Forging

This steel grade is not easy to forge due to the risk of overheating at the high forging temperatures required. Forging is usually carried out in a temperature range of 1150 – 950 °C, followed by cooling in air. Low forging temperatures are preferred to minimise the risk of hot cracks.

Heat treatment after forging can be carried out to restore the properties, reduce internal stresses, and restore the corrosion resistance of material 1.4305.

1.4305 Welding

Welding this grade is not recommended. Its high sulphur content can lead to hot cracks and also reduce corrosion resistance.

If welding is unavoidable, care should be taken to use a suitable filler material and/or electrode. However, the quality of the weld will be impaired and susceptible to further damage, so welding should be avoided wherever possible.

1.4305 Fabrication

To avoid contamination during production with 1.4305, only tools suitable for stainless steels should be used to prevent surface discolouration of the manufactured products. Also clean all tools and work surfaces thoroughly to prevent contamination from foreign matter.