1.4404 / 1.4401 - AT A GLANCE

What kind of steel is the 1.4404 / 1.4401?

The 1.4404 / 1.4401 Stahl (X2CrNiMo17-12-2 | X5CrNiMo17-12-2) are austenitic chromium-nickel-molybdenum stainless steels, resistant to general corrosion and pitting, polishable, good weldability and non-magnetizable.

Properties

As the second most commonly used stainless steel and with the addition of 2 – 2.5% of molybdenum, 1.4404 / 1.4401 exhibit better corrosion resistance, even in the presence of chlorides, and are stronger at elevated temperatures. Both, low temperature applications are possible, as well as applications up to 550°C.

Both alloys provide higher creep resistance, stress rupture and tensile strength at elevated temperatures. Typical for austenitic stainless steels they are both non-hardenable by heat treatment and provide excellent processing capability and formability.

These two stainless steel grades are widely used due to their excellent corrosion resistance. They offer excellent resistance in a wide range of chemicals and find their use in chemical processing equipment but also in marine applications.

Dual certification is given to the 1.4404 / 1.4401 which means both materials meet the chemical and mechanical properties and strictest requirements of both grades. This gives the user more flexibility and the confidence to interchange the materials in applications either one is specified.

Specificly this means for you:

- V4A (Testphase 4 Austenite) steel

- Corrosion resistant

- Heat resistant

- Acid resistant

- Not magnetisable

- Usable in minus temperatures

- Resistant to general and pitting corrosion

- Weldable

- Polishable

- Nitritable

- EDM machinable

- Usable up to a temperature of 550°C

- Forgable between 900 – 1200°C

- More corrosion resistant than 1.4301 / 1.4307

Applications

Stainless steel 1.4404 / 1.4401 can be used in many industries. When choosing between the two steel grades it is important to consider for which appications and which properties as well as what environment parts and workpieces are used for and in.

1.4404 can be used in the food processing industry, and the 1.4401 as a pharmaceutical grade for processing and storing of chemicals, in the paper industy and in the pharma industry due to its resistance to chloride and acids. Both find their uses in the automotiv- as well as the aviation industry.

- Chemical industry

- Pharma industry

- Food processing industry

- Valve- and plant industry

- Building industry

- Automotive industy

- Aviation industry

- Mechanical engineering

- Offshore

- Petrochemical industry

- Electrical equipment

- Decorative uses

- Kitchen equipment

1.4404 / 1.4401 Standard values

Chemical composition:

| C | Si | Mn | P | S | Cr | Mo | Ni | N |

|---|---|---|---|---|---|---|---|---|

| 0.0 - 0.7 | 0.0 - 1.0 | 0.0 - 2.0 | 0.0 - 0.045 | 0.0 - 0.03 | 16.5 - 18.5 | 2.0 - 2.50 | 10.0 - 13.0 | 0.0 - 0.1 |

Chemical designation:

X2CrNiMo17-12-2 / X5CrNiMo17-12-2

Working hardness:

approx. 215 HB (delivery condition)

Delivery condition:

max. 215 HB

1.4404 / 1.4401 Physical properties

What group of steel does the 1.4404 / 1.4401 belong to?

- Austenitic stainless steel

- Stainless steel, corrosion resistance

- Stainless steel, acid resistance

- Stainless steel

- V4A

- Free-cutting steel

What is the difference between 1.4404 and 1.4401?

Unlike 1.4401, the 1.4404 has a low carbon content, which makes it highly resistant to sensitisation (carbide precipitation at the grain boundary). It is therefore widely used for thick welded components, enabling it to be used in a variety of corrosive applications in a welded state.

Stainless steel 1.4401 has a mass fraction of 0.08% carbon, while 1.4404 has a mass fraction of 0.03%.

1.4404 / 1.4401 General corrosion resistance

1.4404 / 1.4401 is significantly more resistant than other chrome-nickel steels to a range of complex sulphur compounds, such as those used in the paper industry. At temperatures up to 48 °C, 1.4404 / 1.4401 alloys are resistant to concentrations of sulphuric acid up to 5%. At temperatures below 30 °C, they exhibit excellent resistance to higher concentrations.

1.4404 / 1.4401 is acid-resistant, temperature-resistant, chlorine-resistant, seawater-resistant and food-safe.

1.4404 / 1.4401 Gas corrosion

The corrosion resistance of these alloys is lower in sulphurous flue gases. In such environments, 1.4404 / 1.4401 can be used at temperatures up to 600 – 750 °C, depending on the conditions of use. It is important to consider whether the atmosphere is oxidising or reducing, i.e. how high the oxygen content is, and whether impurities such as sodium and vanadium are present.

1.4404 / 1.4401 Crevice/pitting corrosion

In the presence of chloride or halide ions, austenitic stainless steels with higher chromium, molybdenum and nitrogen contents are resistant to pitting and/or crevice corrosion. The molybdenum in these steels tolerates water with up to 2,000 ppm chloride. Although they are considered suitable for some applications in marine environments, such as boat railings or building facades near the sea, they are not recommended in seawater with a chloride content of 19,000 ppm.

1.4404 / 1.4401 Intergranular corrosion

Intergranular corrosion is the result of chromium carbide precipitation at the grain boundaries of 1.4401 when exposed to temperatures between 427 and 816 °C.

To avoid intercrystalline corrosion, 1.4404 with its lower carbon content can be used for applications where large cross-sections cannot be annealed after welding, where lower temperatures are desired for stress relief, or where they are exposed to temperatures of 427–816 °C for short periods.

Without impairing the normally excellent corrosion resistance of 1.4404, a short stress relief annealing can be carried out.

1.4404 / 1.4401 Atmospheric corrosion

The addition of molybdenum gives stainless steel maximum resistance to rust and pitting, which is why austenitic stainless steels are superior to almost all other materials. These grades are regularly used in atmospheres where chlorides, sulphur compounds and solids occur either individually or in combination.

1.4404 / 1.4401 Resistance to oxidation

Stainless steels 1.4404 / 1.4401 can be used for short periods at temperatures up to 870 °C or at a constant temperature of 925 °C and still have good oxidation resistance. The temperature range of 454–845 °C is not recommended for stainless steel 1.4401, as there is a possibility of carbide precipitation, but it performs well at different temperatures above or below this range. For applications in the latter temperature range, the 1.4404 should be used.

1.4404 / 1.4401 Stress corrossion cracking

Austenitic steels are susceptible to stress corrosion cracking, which may occur at temperatures above 60 °C when the steel is subjected to tensile stresses or comes into contact with chloride-containing solutions, for example.

Is the 1.4404 / 1.4401 magnetisable?

As an austenitic stainless steel the 1.4404 / 1.4401 is not magnetisable and not suitable for magnetic clamping.

1.4404 / 1.4401 Hot work

All standard hot forming processes are possible and are carried out in a temperature range of 1149–1260 °C. Hot forming should be avoided below a temperature of 927 °C. Annealing is recommended after machining to ensure optimum corrosion resistance.

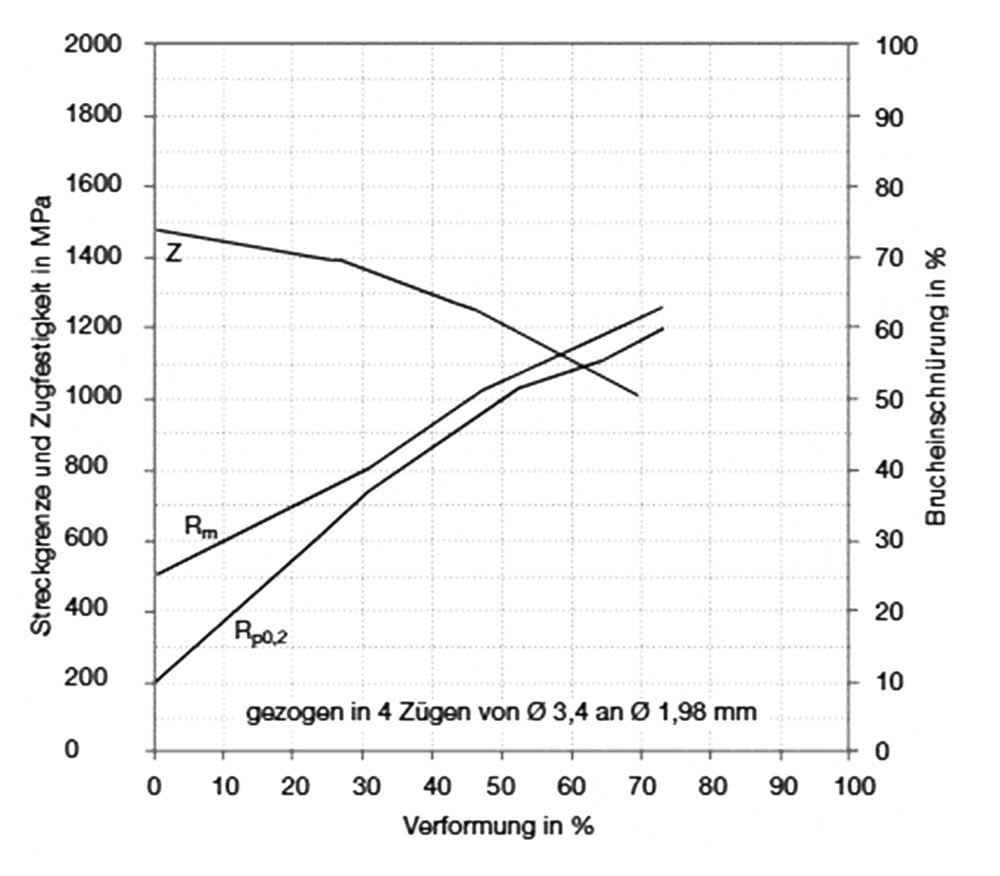

1.4404 / 1.4401 Cold work

The 1.4404 / 1.4401 is suitable for drawing and heading and can be easily formed at room temperature. This process makes the steel harder and stronger, but also less ductile. Post-annealing should be carried out to restore some of its toughness.

1.4404 / 1.4401 Wear resistance

This stainless steel receives a 2 for it wear resistance on a scale where 1 is low and 6 is high.

1.4404 / 1.4401 Technical properties

Is stainless steel 1.4404 / 1.4401 a knife steel?

1.4404 / 1.4401 is not normally used as knife steel. It does not have the required edge retention due to its lower carbon content. Although it has good toughness, which makes it resistant to chipping and breaking, this in turn compromises its edge retention. The low carbon content makes this steel softer than other knife steels, which makes it easier to sharpen but also means it needs to be sharpened more often.

1.4404 / 1.4401 Working hardness

The working hardness for stainless steel 1.4404 / 1.4401 is at 215 HB.

1.4404 / 1.4401 Density

At room temperature the typical density of the 1.4404 / 1.4401 is 8,0 g/cm3.

1.4404 / 1.4401 tensile strength

1.4404 / 1.4401 has a tensile strength of approx. 690 N/mm2. This value is the result of a tensile test that shows how much force is required before the material begins to stretch or deform before it breaks.

1.4404 / 1.4401 Yield strength

The yield strength indicates how much stress can be exerted on a material before it undergoes plastic deformation. Beyond this point, it will not return to its original shape, even if the stress is removed. The material will deform permanently or break beyond this point.

The yield strength for 1.4404 / 1.4401 stainless steel is at 200 N/mm2.

1.4404 / 1.4401 Machinability

During forming, 1.4404 / 1.4401 is subject to cold work hardening and chip breaking. For the best possible machining results, it is recommended to use slower speeds, sufficient lubrication, sharp tools, higher feed rates and high-performance machines.

The material 1.4404 / 1.4401 receives a 2 for its machinability on a scale where 1 is low and 6 is high.

1.4404 / 1.4401 Heat resistance

With a good resistance to oxidation at temperatures up to 870 °C the 1.4401 can be used intermittantly and continuously up to 925 °C. It is not recommended to use the 1.4401 in a temperature range of 425 – 860 °C continuously if parts are going to be used in a water based environment as the corrosion resistance will deteriorate.

The 1.4404 can be used in the former meantioned temperature range as it is more resistant to carbide precipitation.

1.4404 / 1.4401 Heat conductivity

The heat conductivity for the 1.4404 / 1.4401 is in a temperature of 20 °C is at 15 W/(m*K).

1.4404 / 1.4401 Thermal expansion coefficient

The following table shows the expansion or contraction at different temperatures, which can be very important for work at high temperatures or with significant temperature fluctuations.

Medium thermal expansion coefficient

Value 10-6m/(m*K)

At a temperature of

16.0

20 – 100 °C

16.5

20 – 200 °C

17.0

20 – 300 °C

17.5

20 – 400 °C

18.0

20 – 500 °C

1.4404 / 1.4401 Specific heat capacity

The specific heat capacity for stainless steel 1.4404 / 1.4401 at room temperature is 0,5 J/kg*K. This value indicates how much heat is required to heat a certain amount of material by 1 Kelvin.

1.4404 / 1.4401 Specific electrical resistance

The specific electrical resistance for stainless steel 1.4401 / 1.4404 can be found in the following table. Electrical conductivity is the reciprocal of specific resistance.

Specific electrical resistance

Value (Ohm*mm2)/m

At a temperature of

0.74

20 °C

BECOME EVEN BETTER WITH ABRAMS PREMIUM STEEL® THAN YOUR COMPETITORS SUSPECT!

1.4404 / 1.4401 Procedure

1.4404 / 1.4401 Heat treatment

1.4404 / 1.4401 cannot be hardened by heat treatment, but cold working increases both tensile strength and hardness. Heat treatment during or after manufacturing may be necessary to eliminate the effects of cold working or to dissolve the chromium carbides precipitated by the heat.

1.4404 / 1.4401 Soloution annealing

Heat the 1.4401 / 1.4404 to a temperature of 1020 – 1120 °C. Depending on sizes of the work pieces they are then quenched in water or air.

1.4404 / 1.4401 Stress relieving

Due to its lower carbon content the 1.4404 can be stress relieved at a temperature of 454 – 593 °C for 60 minutes. The danger of sensetisation is minimal here.

The 1.4401 should be stress relieved at lower temperatures, not exceeding 399 °C but with a longer holding time as for this grade sensitisation in the grain bounderies may occur which can result in a loss of corrosion resistance. Stress relieving above 593 °C is not recommended.

1.4404 / 1.4401 Hardening

The 1.4404 / 1.4401 is not hardenable by heat treatment.

As an austnitic stainless steel steel grades 1.4404 / 1.4401 can be hardened by cold forming. Care should be taken as to which extent it can be hardened by cold work as the material can get brittle and sensitive to stress corrosion cracking.

1.4404 / 1.4401 Sub-zero treatment

Normally this process is done to convert remaining austenite back to martensite. With an austenitic structure the 1.4404 / 1.4401 keeps its existing structure.

The sub-zero treatment can improve the mechanical properties, resistance to stress corrosion cracking and slight improvement of the pitting and wear resistance. Though the 1.4404 / 1.4401 has gerneally good cryogenic properties care should be taken as cryogenic embrittlement is a potential risk at sub-zero temperatures.

1.4404 / 1.4401 Surface treatment

To improve properties as well as appearance the 1.4404 / 1.4401 can undergo a surface treatment.

1.4404 / 1.4401 Nitriding

During the nitriding process nitrogene diffuses into the material surface. This gives the material a harder outer layer. However, it can reduce the corrosion resistance and should be regarded if the corrosion resistance is of high importance.

1.4404 / 1.4401 Passivation

Generally passivation improves the corrosion resistance due to a passive oxide layer ensuring the surface is less reactive to its surrounding environment. Passivation ensures a contaminant free surface which prevents contamination which is important when uses in the food processing industry for example for food containers.

1.4404 / 1.4401 Pickling

Parts are immersed in an acid bath to remove impurities like scale and rust. After pickling other surface treatments for example passivation (see Passivation) can follow this process.

1.4404 / 1.4401 Abrasive blasting

Under high pressure abrasive particles are propelled against the surface of the material. This process is used to clean contaminants like paint, rust or scale of the surface and to promote a better surface texture or finish.

Glas beads, silica sand, steel grit, coal or copper but also organic materials like walnut shells or corn cob for a less agressive cleaning are used as abrasive particles. Abrasive blasting can be done dry where the particles are propeld by air or wet where the particle are mixed with water.

1.4404 / 1.4401 Processing

During forming, 1.4404 / 1.4401 is subject to work hardening and chip breaking. For best machining results, it is recommended to use slower speeds, sufficient lubrication, sharp tools, higher feed rates and high-performance machines.

1.4404 / 1.4401 Electrical Discharge Machining (EDM)

Stainless steel 1.4404 / 1.4401 can be machined by erosion. The parameter settings, the selection of the correct electrode and the desired surface finish must be taken into account. Material properties may change slightly in the heat-affected zones. The recast layer should be removed to obtain a clean and smooth surface.

1.4404 / 1.4401 Dimensional changes

Like all materials, stainless steels 1.4404 / 1.4401 expand during heat treatment and then contract again. As with this process, dimensional changes should be carefully taken into account when processing steel, especially if it is used for work at high temperatures or is exposed to temperature fluctuations.

1.4404 / 1.4401 Welding

Stainless steel 1.4401 is weldable and can be welded using all common welding processes. Filler materials should be of the same or better quality than the base material. 1.4401 should be annealed after welding to remove any chromium carbide precipitates. Weld discolouration should be removed by pickling and passivation to restore maximum corrosion resistance.