1.4571 - AT A GLANCE

What kind of steel is the 1.4571?

Like other austenitic steels, stainless steel 1.4571, also know as the 6CrNiMoTi17-12-2, cannot be magnetized. Also it cannot be hardened by heat treatment. Cold forming of the material causes a change in the microstructure and therefore work hardening, which increases tensile strength, yield strength and hardness. It has very good corrosion resistance, under certain circumstances excellent weldability and high durability, which helps in applications like furnace parts, heat exchangers, brewery equipment and medical implants or for the storage and transportation of milk for example.

Properties

The 1.4571 is an austenitic stainless steel that is resistant, due to the addition of titanium, to sensitization at high temperatures. It is suitable for applications where heat-induced intergranular corrosion is a problem and a variety of aggressive environments.

- Austenitic stainless steel

- Austenitic chromium-nickel-molybdenum steel

- Seawater resistant

- Resistant to diluted sulphuric and hydrochloric acid

- Resistant to intergranular corrosion after welding

- Very good cold formability

- Very good weldability

- Non-magnetizable

Applications

Due to the stabilizing titanium in this material it can be used in environments with high temperatures as well as in corrosive environments like chlorides or sulphorus environments. It can be used for chemical processing applications and in the pulp and paper industry where chemicals and high temperatures are used/needed.

- Chemical industry

- Textile industry

- Oil industry

- Building industry

- Food industry

- Soap industry

- Paper industry

- Photographic industry

- Paint industry

- Rubber industry

- Mechanical engineering

- Apparatus engineering

- Pump construction

- Compressor construction

- Pipeline construction

- Shipbuilding

- Medical technology

- Pharmaceutical industry

- Nuclear engineering

1.4571 Standard values

Chemical composition:

| C | Si | Mn | P | S | Cr | Mo | Ni | Ti |

|---|---|---|---|---|---|---|---|---|

| 0.0 - 0.08 | 0.0 - 1.0 | 0.0 - 2.0 | 0.0 - 0.045 | 0.0 - 0.015 | 16.5 - 18.5 | 2.0 - 2.5 | 10.5 - 13.5 | 0.0 - 0.7 |

Chemical designation:

X6CrNiMoTi17-12-2

Delivery condition:

max. <20 HCR

Working hardness:

max. 215 HB

1.4571 Physical properties

What group of steel does the 1.4571 belong to?

- Austenitic stainless steel

- Stainless steel, corrosion resistant

- Stainless steel, acid resistant

- Stainless steel

- Chromium steel

- V4A steel

Is the 1.4571 a stainless steel?

Yes, the 1.4571 is a classical stainless steel. Such steel has to have a mass fraction of at least 10,5 % of chromium.

Is the 1.4571 corrosion resistant?

With a mass fraction of 16,5 – 18,5 % of chromium the 1.4571 is corrosion resistant.

1.4571 General corrosion resistance

1.4571 has good resistance to atmosphere, fresh water, fruit and vegetable juices, and moderate resistance to diluted acids such as diluted sulphuric acid and hydrochloric acid. It is also resistant to intergranular corrosion after welding.

1.4571 Gas corrosion

The 1.4571 can be used in air with tempratures up to 850 °C and steam with temperatures up to 750 °C.

It is corrosion resistant in reduced sulphurous flue gasses and depending on service conditions can be used in such environments at temperatures of 600 – 750 °C. Consideration should be given to weather the atmosphere is oxidising or reducing, e.g. in terms of the oxygen content, and whether impurities such as sodium and vandium are present.

1.4571 Pitting / Crevice corrosion

The added molybdenum lets the 1.4571 handle water with up to 2.000 ppm of chloride. Tough considred adequate for some pallications exposed to salt spray it is not recommended for sea water containing 19.000 ppm of chloride.

1.4571 Intergranular corrosion

After prolonged heating in a temperature range of 450–850 °C, the added titanium prevents the precipitation of chromium carbides in the grain boundaries.

1.4571 Stress corrosion cracking

Exposure to tensile stresses or simultaneous contact with chloride-containing solutions at temperatures above 60 °C, for example, can lead to stress corrosion cracking, as austenitic steels are susceptible to this.

Is stainless steel 1.4571 magnetisable?

As an austenitic steel the 1.4571 is not magnetisable and not suitable for magnetic clamping. During cold forming for example this material can get slightly magnetic.

1.4571 Hot work

Heat the material to a minimum temperature of 900 °C and do not let it drop below the 900 °C during the process. The ideal temperature range for hot work for the 1.4571 is between 1150 – 1260 °C followed to finish the process with a cool down in air. To ensure maximum corrosion resistance it is recommended to anneal the material afterwards.

1.4571 Cold work

Stainless steel 1.4571 has good cold forming properties and can be rolled, punched, drawn and swaged. Post annealing is recommended to reduce internal stresses. Cold forming increases both the strength and hardness of this steel grade.

1.4571 Wear resistance

On a scale where 1 is low and 6 is high this stainless steel receives a 2 for its wear resistance.

1.4571 Technical properties

Is the stainless steel 1.4571 a knife steel?

The 1.4571 is not normally used for manufacturing knives as it does not hold an edge very well due to its low carbon content. Its good toughness makes it resistant to chipping and breaking, this in turn jepordises its edge retention. Its corrosion resistance is not enough to make this grade a good knife steel. A good knife steel has a good balance of hardness and corrosion resistance.

1.4571 Working hardness

The working hardness for stainless steel 1.4571 is at 215 HB.

1.4571 Density

At room temperature stainless steel 1.4571 has a density of 8,0 g/cm3.

1.4571 Tensile strength

The 1.4571 has a tensile strength of approx. 690 N/mm2. This value is the result of a tensile test that shows how much force is required before the material begins to stretch or deform before it breaks.

1.4571 Yield strength

The yield strength indicates how much stress can be exerted on a material before it undergoes plastic deformation. Beyond this point, it will not return to its original shape, even if the stress is removed. The material will deform permanently or break beyond this point.

The yield strength for 1.4571 stainless steel is at 200 N/mm2.

1.4571 Machinability

To avoid excessive work hardening, the cutting edges of tools have to be sharp. Lubricants and coolants should be used generously to prevent heat build-up at the cutting edges. Chip breakers should be used to keep the workpiece free.

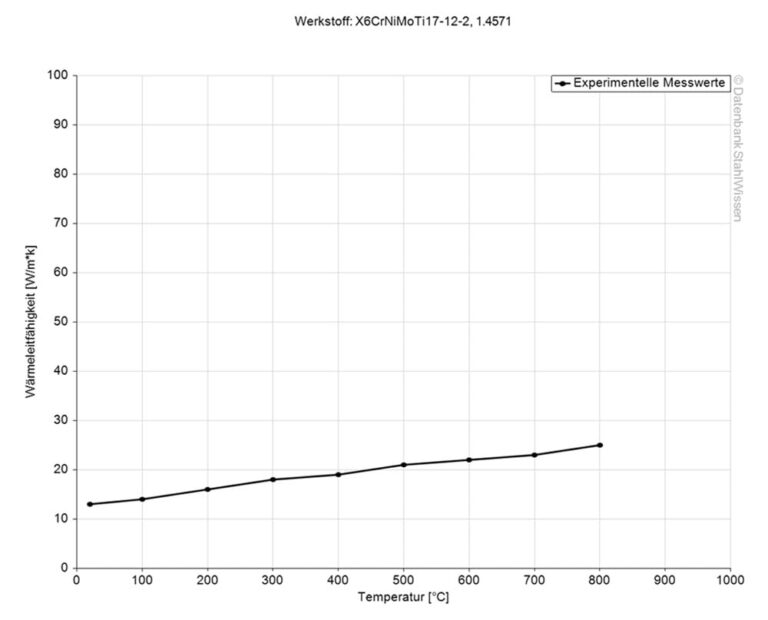

1.4571 Heat conductivity

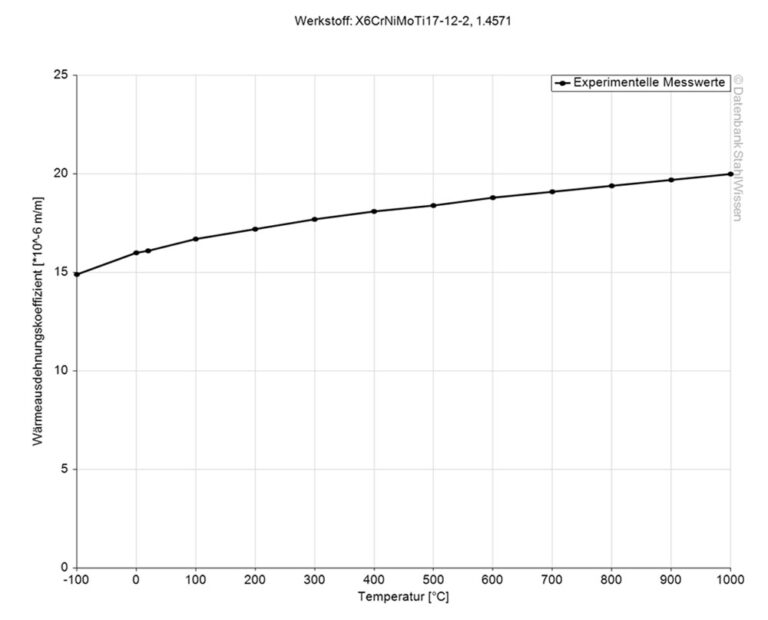

1.4571 Termal expansion coefficient

The coefficient of thermal expansion indicates how much the material can expand or contract when the temperature changes. This is very important information, especially when working with high temperatures or when there are significant temperature fluctuations during use.

Medium thermal expansion coefficient

Value 10-6m/(m*K)

At a temperature of

16.5

20 – 100 °C

17.5

20 – 200 °C

18.0

20 – 300 °C

18.5

20 – 400 °C

19.0

20 – 500 °C

19.0

20 – 600 °C

19.5

20 – 700 °C

19.5

20 – 800 °C

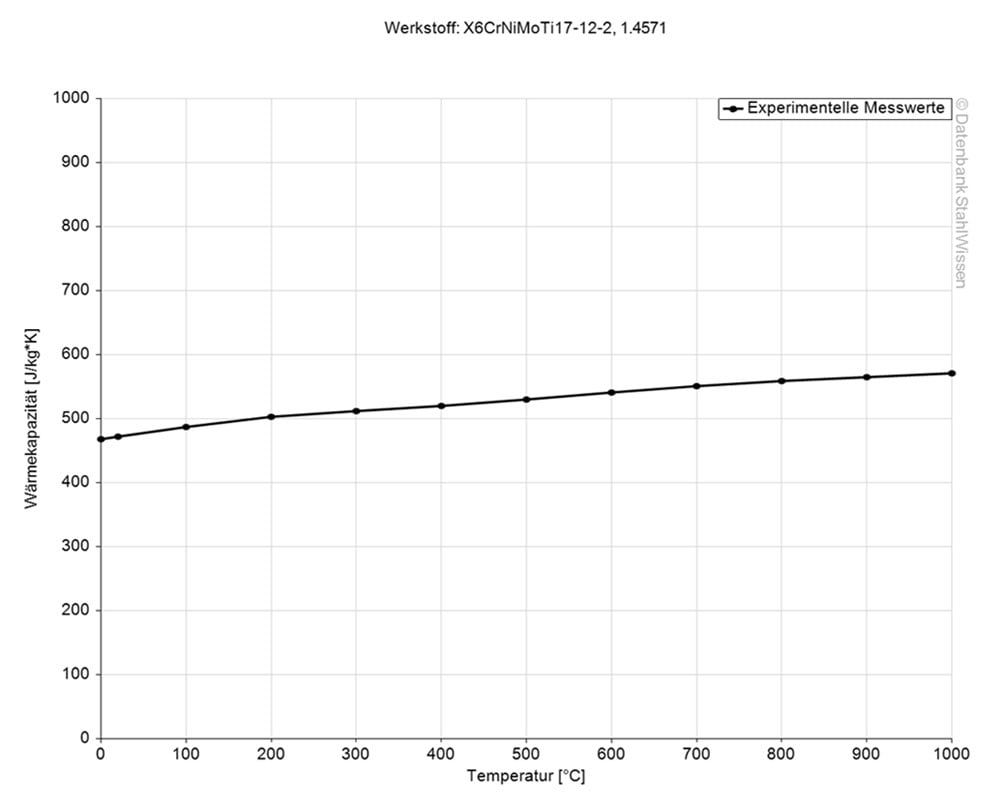

1.4571 Specific heat capacity

The specific heat capacity for stainless steel 1.4571 at room temperature is 0,5 J/kg*K. This value indicates how much heat is required to heat a certain amount of material by 1 Kelvin.

1.4571 Specific electrical resistance

The specific electrical resistance for stainless steel 1.4571 can be found in the following table. Electrical conductivity is the reciprocal of specific resistance.

Specific electrical resistance

Value (Ohm*mm²)/m

At a temperature of

0.75

20 °C

PERFEKTION!

1.4571 Procedure

1.4571 Heat treatment

A heat treatment is used to determine material properties. It should therefore always be carried out with care. Properties such as strength, toughness, surface hardness and temperature resistance are determined, which in turn can extend/improve the service life of parts, tools and components.

Heat treatment includes solution annealing, soft annealing, normalising, stress relief annealing, but also tempering, hardening and quenching or tempering.

1.4571 Annealing

Evenly heat the material to a tempreature of 1020 – 1110 °C and cool it down after in water or air.

1.4571 Quenching

Work pieces over 2 mm should be quenched in water from a temperature of 1020 – 1110 °C. Work pieces under 2 mm should be quenched in air.

1.4571 Surface treatment

1.4571 Passivation

Passivation involves removing free iron from the surface by treating it with an acid solution, such as citric or nitric acid. Passivation creates a protective oxide layer that increases the corrosion resistance of this material.

1.4571 Bead blasting

Abrasive particles such as glass or ceramic beads are blasted against the surface to remove contaminants such as rust, paint or scale and achieve a uniform matt finish. It makes the surface more resistant and can prevent fatigue and stress corrosion damage.

1.4571 Shot peening

Shot peening is an impact treatment in which multiple high-speed shots are fired at the material surface, creating small indentations that eliminate stress peaks. This makes the surface more resistant and can prevent fatigue and stress corrosion damage.

1.4571 PVD coating

In PVD (physical vapour deposition) treatment, a thin layer is applied to the surface of the material. This treatment can give the steel a unique colour and improve its surface properties.

1.4571 Electro polishing

Electropolishing is a non-mechanical chemical process in which a thin layer of material is removed using an electric current to give the material a smooth and shiny surface. This process should not be confused with passivation, which is also a non-mechanical chemical process but does not use electricity.

1.4571 Processing

1.4571 Dimensional changes

Plastic deformation due to mechanical stresses, phase changes and local heating and cooling during welding can lead to dimensional changes. Like all metallic materials, the 1.4571 expands at certain temperatures and contracts when the temperature changes. For more information, please refer to our diagram for the coefficient of thermal expansion.

1.4571 Forging

Heat the workpiece to approx. 1150 – 1180 °C. Forging takes place in the temperature range of 1180 – 950 °C, followed by air or water cooling.

1.4571 Welding

Stainless steel 1.4571 can be welded using most common welding processes, with or without welding consumables. However, gas welding should be avoided as there is a risk of carburisation. Heat treatment after welding is not necessary. Discolouration can be removed chemically or mechanically to maintain the best possible corrosion resistance.

1.4571 Fabrication

During production, avoid contaminating the material with the tools used. To prevent this contamination, only tools suitable for stainless steel should be used, which will avoid damaging the surface of the products. Clean all tools and work surfaces thoroughly to prevent contamination.