1.6582 - AT A GLANCE

What kind of steel is the 1.6582?

The steel grade 1.6582 (here in its tempered condition), also known under its chemical discription 34CrNiMo6, is a CrNiMO alloyed structural steel.

Due to its good mechanical properties like its strength and toughness he is often used for parts that are subjected to high stresses. Hardened through this material is used for parts in automotive or machine engineering. Components are usuall used as delivered in the quenched and tempered condition.

Properties

This material offers a good balance between strength, toughness and machinability, making it a good choice for a range of industries and applications.

- Heat treatable steel

- High strength

- High toughness

- Parts can be used in the delivered condition

- Nitridable to a surface hardness of approx. 58 – 62 HRC

Applications

The material 1.6582 is used for components with high strength and toughness. Components are usually used in the quenched and tempered delivery condition. However, the material can also be hardened very well and can then also be used for components in car or machine construction.

- Fasteners

- Mechanical engineering

- Gears

- Shafts

- Axles

- Bolts

- Automotive engineering / engine construction

- Crankshafts

- Camshafts

- Gear parts

1.6582 Standard values

Chemical composition:

| C | Si | Mn | P | S | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|

| 0.3 - 0.38 | 0.0 - 0.4 | 0.5 - 0.8 | 0.0 - 0.025 | 0.0 - 0.035 | 1.3 - 1.7 | 0.15 - 0.3 | 1.3 - 1.7 |

Chemical designation:

34CrNiMo6

Working hardness:

max. 38 HRC

Delivery condition:

max. 352 HB

1.6582 Physical properties

What group of steel does the 1.6582 belong to?

- Heat-treatable steel

Is the 1.6582 a stainless steel?

To be classified as stainless steel, a material must have a mass fraction of at least 10,5% chromium. With a mass fraction of 1,3 – 1,7%, 1.6582 is therefore not stainless steel in the classical sense.

Is the 1.6582 corrosion resistant?

The corrosion resistance of steel begins at a mass fraction of 10,5% chromium. With a chromium content of 1,5 – 1,8%, 1.6582 is therefore not corrosion resistant.

Is the 1.6582 magnetisable?

As a ferromagnetic material, the 1.6582 is magnetisable and can be clamped onto magnetic plates for machining operations such as milling, grinding and eroding.

1.6582 Wear resistance

On a scale where 1 is low and 6 is high the 1.6582 receives a 3 for its wear resistance.

1.6582 technical properties

Is the 1.6582 a knife steel?

1.6582 is not suitable for knives. Its carbon content, for example, is not high enough to achieve the necessary hardness and edge retention.

1.6582 Working hardness

The working hardness for the heat-treatable steel 1.6582 is at approx. 58 – 62 HRC.

1.6582 Density

Typically, the density of 1.6582 steel at room temperature is 7.73 g/cm³.

1.6582 Tensile strength

The tensile strength for the 1.6582 is approx. 1200 N/mm2. A tensile test is carried out to obtain this information, which shows how much load is required to stretch or elongate a sample before it breaks.

1.6582 Yield strength

Yield strength

Dimension

Value

<= 16 mm

>= 1000 MPa

17 – 40 mm

>= 900 MPa

41 – 100 mm

>= 800 MPa

101 – 160 mm

>= 700 MPa

1.6582 Machinability

On a scale where 1 is low and 6 is high, the 1.6582 heat-treatable steel receives a 3 for its machinability.

1.6582 Heat conductivity

The heat conductivity for the 1.6582 at room temperature is at 42,6 W/(m*K).

1.6582 Thermal expansion coefficient

The following table shows how much the 1.6582 can expand or contract when temperatures change. This can be very important when working with high temperatures or large temperature fluctuations.

Medium thermal expansion coefficient

Value 10-6m/(m*K)

At a temperature of

11.1

20 – 100 °C

12.1

20 – 200 °C

12.9

20 – 300 °C

13.5

20 – 400 °C

1.6582 Specific heat capacity

The specific heat capacity for the 1.6582 at room temperature is at 0,47 J/g-°C. This value indicates how much heat is required to heat a certain amount of material by 1 Kelvin.

1.6582 Specific electrical resistance

The specific electrical resistance for the 1.6580 can be found in the following table. Electrical conductivity is the reciprocal of specific resistance.

Specific electrical resistance

Value (Ohm*mm²)/m

At a temperature of

0.19

20 °C

ABRAMS PREMIUM STEEL® – QUALITY THAT WILL IMPRESS YOU!

1.6582 Procedure

1.6582 Heat treatment

The heat treatment determines material properties. It should therefore always be carried out with care. Properties such as strength, toughness, surface hardness and temperature resistance are determined, which in turn can extend/improve the service life of parts, tools and components.

Heat treatment includes solution annealing, soft annealing, normalising and stress relief annealing, as well as tempering, hardening and quenching or tempering.

1.6582 Normalising

For normalising, the 1.6582 is heated to a temperature of 850–880 °C. It is then cooled in air.

1.6582 Annealing

To anneal material grade 1.6582 heat it to the temperature of 850 – 880 °C. Then cooling it back down in air.

1.6582 Stress reliving

Since material grade 1.6582 is in the quenched and tempered condition here, it is stress-relieved in this state at approx. 30–50 °C below the tempering temperature. The workpieces are held at this temperature for at least 1 hour.

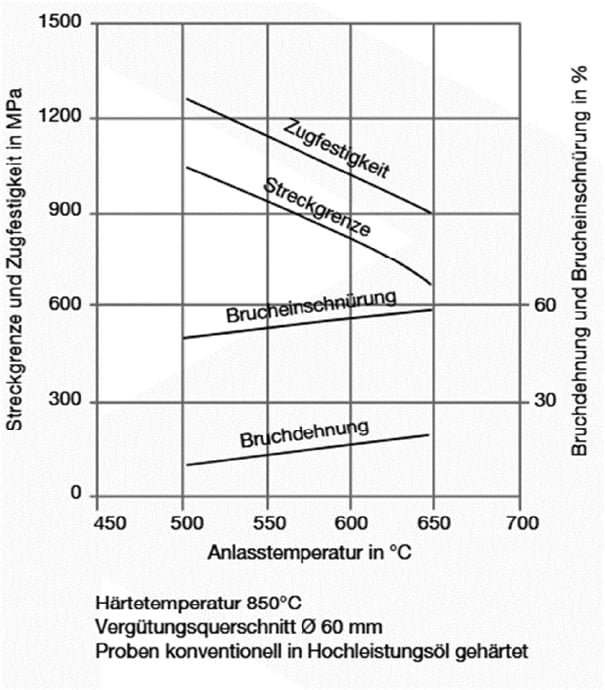

1.6582 Tempering

To temper this material grade it is heated to a temperature of 540 – 680 °C and held for an hour. This is followed by a cool down in air.

Further information can be taken from the following diagram.

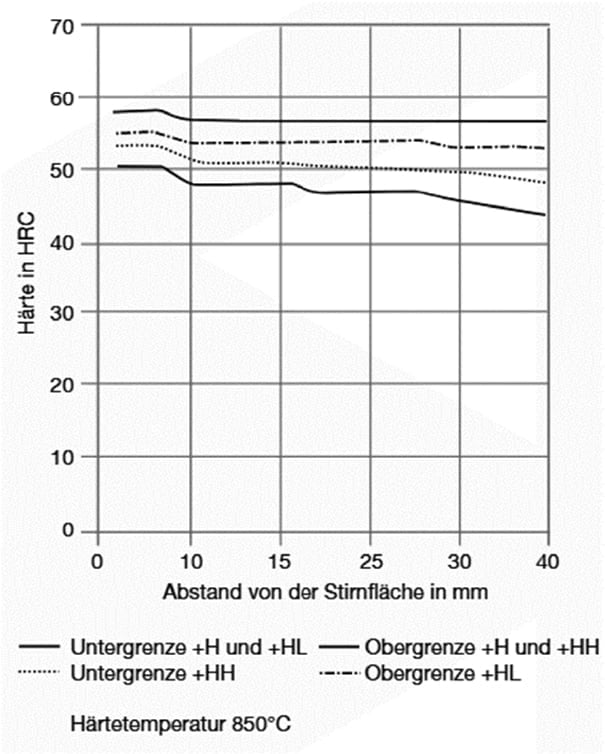

1.6582 Hardening

Heat the work pieces made with the 1.6582 to a temperature of 830 – 860 °C and finish this of with a quenching.

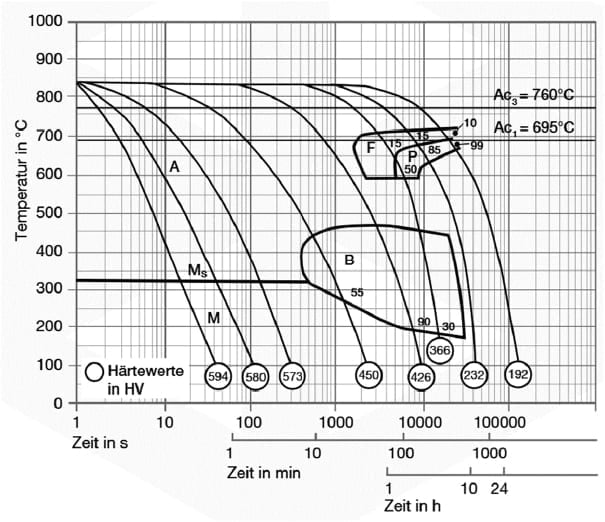

1.6582 Continuous TTT-Diagram

This diagram shows micro-changes over time at different temperatures. These are important in heat treatment because they provide information about the optimal conditions for processes such as hardening, annealing and normalising.

1.6582 Surface treatment

The surface treatment of the 1.6582 offers advantages such as a longer service life, improved performance, corrosion resistance and enhanced visual appeal of workpieces made from this steel grade.

Below are some examples of surface treatments that can be applied to 1.6582 workpieces.

1.6582 Nitriding

During nitriding, nitrogene is diffused into the surface of the steel. This gives the steel a harder and more wear resistant surface and can improve service life and corrosion resistance.

1.6582 Induction hardening (casehardening)

Induction hardening is a fast, selective and targeted heating of the surface of a workpiece. The surface is heated by the electrical resistance of the material using induction (alternating electrical voltage).

Various inductors are used to heat the material surface in a focused manner, thereby hardening specific areas of the workpiece. This allows highly stressed areas and even complex geometries to be hardened.

After induction hardening, the material is immediately quenched.

1.6582 Carburising / Gas carburisation

To prevent harmful oxides from forming on the surface and grain boundaries, gas carburising is carried out in a controlled atmosphere. In such an atmosphere, carbon is introduced into the surface layer of the material to create a more wear-resistant and harder surface. Gas carburising is used on materials with a low carbon content to give them greater hardness and a more wear-resistant surface with a tough core.

1.6582 Phosphate coating

In this process, a phosphate solution is sprayed onto the component or it is immersed in a phosphate solution. The resulting phosphate layer on the component improves corrosion resistance and can also form the basis for further coating, such as painting.

1.6582 Black oxide coating or blueing

Before oxidation, the material surface is thoroughly cleaned of deposits and adhesions and then immersed in an alkaline aqueous salt solution.

Black oxidation, also known as blueing, is a surface finish that reduces surface reflection and can increase corrosion resistance.

1.6582 Galvanised coating

Galvanising is an electrochemical process in which a layer of chrome, nickel or zinc, to name but a few, is applied to the workpiece. This increases the corrosion resistance and wear resistance of the coated workpieces.

1.6582 PVD coating

In PVD (physical vapour deposition) treatment, a thin layer is applied to the surface of the material. This treatment can give the steel a unique colour and improve its surface properties.

1.6582 Processing

1.6582 Electrical Discharge Machining (EDM)

In general, a material is eroded in order to produce workpieces from a single piece. Erosion can be used to produce dies or more complex shapes. There are various methods of eroding different materials, such as wire erosion, spark erosion or die-sinking erosion.

1.6582 Forging

To forge the 1.6582 heat the material to a temperature of 850 – 1050 °C and forge it. The work pieces are cooled evenly and slowly in the furnace to finish this process.

1.6582 Welding

The material 1.6582 is only suitable for welding to a limited extent and should therefore not be used for welded constructions.