1.6587 - AT A GLANCE

What kind of steel is the 1.6587?

The 1.6587 is a CrNiMo-alloyed case-hardening steel which is used for highly stressed parts which need a high core strength and toughness. The 1.6587 an be surface hardened as well as core hardened. With surface hardening a case hardness off approx. 58 – 60 HRC can be reached.

Properties

Case-hardening steel 1.6587, an alloyed CrNiMo alloyed steel can be used for extremely high stressed parts.

- Case-hardening steel

- Engineering steel

- Core- and surface hardenable

- Nitridable

- Good machinability

- Good toughness

- Good core strength

- Hard to weld

- Can be carburised

Applications

The steel grade 1.6587 can be used for highly stressed gear parts.

- Bevel gears

- Driving pinions

- Gears

- Shafts

- Crankshafts

1.6587 Standard values

Chemical composition:

| C | Si | Mn | P | S | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|

| 0.15 - 0.21 | 0.0 - 0.4 | 0.5 - 0.9 | 0.0 - 0.025 | 0.0 - 0.035 | 1.5 - 1.8 | 0.25 - 0.35 | 1.4 - 1.7 |

Chemical designation:

18CrNiMo7-6

Surface hardenss according to case hardness: approx. 58-60 HRC

Delivery condition:

max. 229 HB

1.6587 Physical properties

What group of steel does the 1.6587 belong to?

- Case hardening steel

- High grade structural steel

Is the 1.6587 a stainless steel?

To be classified as stainless steel, a material must have a mass fraction of at least 10,5% chromium. With a mass fraction of 1,5 – 1,8 %, 1.6582 is therefore not stainless steel in the classical sense.

Is the 1.6587 corrosion resistant?

The corrosion resistance of steel begins at a mass fraction of 10,5% chromium. With a chromium content of 1,5 – 1,8%, 1.6582 is therefore not corrosion resistant.

Is the 1.6587 magnetisable?

As a ferromagnetic material, the 1.6587 is magnetisable and can be clamped onto magnetic plates for machining operations such as milling, grinding and eroding.

1.6587 Wear resistance

On a scale where 1 is low and 6 is high the 1.6587 receives a 5 for its wear resistance.

1.6587 Technical properties

Is the 1.6587 a knife steel?

1.6587 is not suitable for knives. Its carbon content, for example, is not high enough to achieve the necessary hardness and edge retention.

1.6587 Working hardness

The working hardness for the 1.6587 is at approx. 58 – 60 HRC.

1.6587 Density

Typically, the density of 1.6587 steel at room temperature is 7.8 g/cm³.

1.6587 Tensile strength

The tensile strength for the 1.6587 is approx. 770 N/mm2. A tensile test is carried out to obtain this information, which shows how much load is required to stretch or elongate a sample before it breaks.

1.6587 Yield strength

Yield strength

Dimension

Value

<= 11 mm

>= 835 MPa

<= 30 mm

>= 755 MPa

<= 63 mm

>= 685 MPa

1.6587 Machinability

On a scale where 1 is low and 6 is high the 1.6587 receives a 5 for its machinability.

1.6587 Heat conductivity

At room temperature the heat conductivity of the 1.6587 is 39,8 W/(m*K).

1.6587 Thermal expansion coefficient

The following table shows how much the 1.6582 can expand or contract when temperatures change. This can be very important when working with high temperatures or large temperature fluctuations.

Medium thermal expansion coefficient

Value 10-6m/(m*K)

At a temperature of

11.5

20 – 100 °C

12.5

20 – 200 °C

13.3

20 – 300 °C

13.9

20 – 350 °C

1.6587 Specific heat capacity

The specific heat capacity for the 1.6587 at room temperature is at 0,43 J/g-°C. This value indicates how much heat is required to heat a certain amount of material by 1 Kelvin.

1.6587 Specific electrical resistance

The specific electrical resistance for the 1.6587 can be found in the following table. Electrical conductivity is the reciprocal of specific resistance.

Specific electrical resistance

Value (Ohm*mm²)/m

At a temperature of

0.12

20 °C

STEEL MADE WITH ”STYLE“ !

1.6587 Procedure

1.6587 Heat treatment

The heat treatment determines material properties. It should therefore always be carried out with care. Properties such as strength, toughness, surface hardness and temperature resistance are determined, which in turn can extend/improve the service life of parts, tools and components.

Heat treatment includes solution annealing, soft annealing, normalising and stress relief annealing, as well as tempering, hardening and quenching or tempering.

1.6587 Annealing

To anneal the 1.6587 heat it to a temperature of 650 – 700 °C and then cool it down in oil or polymer.

1.6587 Intermediate annealing

For intermediate annealing, this material is heated evenly to a temperature range of 630–650 °C and then cooled in oil or polymer.

1.6587 Tempering

The tempering process for this material grade should be done shortly after the hardening process to avoid cracking. The tempering temperature depends on the surface hardness needed.

For tempering the 1.6587 is heated to a temperature of 150 – 200 °C and held for at least one hour and the cooled in air.

1.6587 Hardening (core hardening)

For core hardening, the 1.6587 is heated to a temperature of 830–870 °C and then quenched.

1.6587 Hardening (case hardening)

For case hardening, the 1.6587 is heated to a temperature of 780–820 °C and then quenched.

1.6587 Quenching

After core or case hardening the material can be quenched in the following media:

- Oil

- Polymer

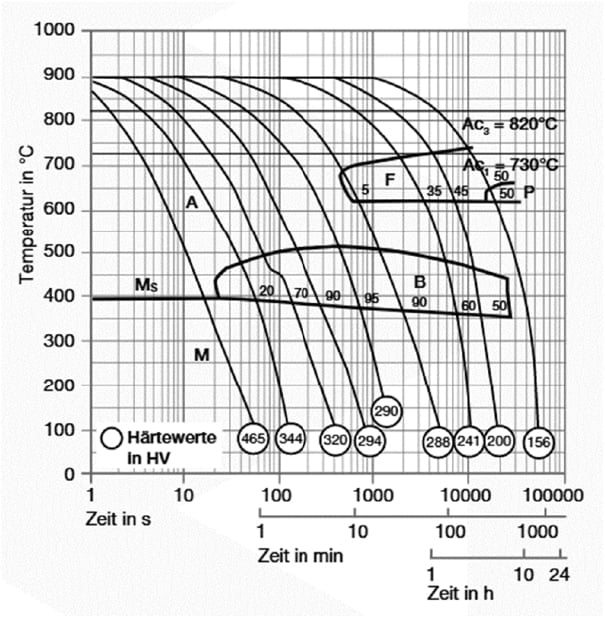

1.6587 Continuous TTT-Diagram

This diagram shows micro-changes over time at different temperatures. These are important in heat treatment because they provide information about the optimal conditions for processes such as hardening, annealing and normalising.

1.6587 Surface treatment

1.6587 Nitriding

During nitriding, nitrogen diffuses into the surface of the steel, giving it a harder and more wear-resistant surface. It can improve service life and corrosion resistance.

1.6587 Carbonitriding

This process causes nitrogen and carbon to diffuse into the surface of the metal, giving it greater hardness and wear resistance.

1.6587 Carburisation

During carburising, carbon diffuses into the surface of the material, giving the surface greater hardness and wear resistance.

1.6587 Induction hardening (case hardening)

Induction hardening is a fast, selective and targeted heating of the surface of a workpiece. The surface is heated by the electrical resistance of the material using induction (alternating electrical voltage).

Various inductors are used to heat the material surface in a focused manner, thereby hardening specific areas of the workpiece. This allows highly stressed areas and even complex geometries to be hardened.

After induction hardening, the material is immediately quenched.

1.6587 Phosphate coating

In this process, a phosphate solution is sprayed onto the component or it is immersed in a phosphate solution. The resulting phosphate layer on the component improves corrosion resistance and can also form the basis for further coating, such as painting.

1.6587 PVD coating

In PVD treatment (physical vapour deposition), a thin layer is applied to the surface of the material. This thin, hard layer gives the material a wear-resistant coating.

1.6587 Processing

1.6587 Electrical Discharge Machining (EDM)

In general, a material is eroded in order to produce workpieces from a single piece. Erosion can be used to produce dies or more complex shapes. There are various methods of eroding different materials, such as wire erosion, spark erosion or die-sink erosion.

1.6587 Forging

The 1.6587 is forged in a temperature range of 850 – 1100 °C and forging should not be continued under 850 °C.

After forging the work pieces are cooled slowly and controlled in the furnace or in a medium which endorses low cooling. The slow cooling process prevents internal stresses and cracking to appear.

1.6587 Welding

Material grade 1.6587 is usually hard to weld.