1.7227 - AT A GLANCE

What kind of steel is the 1.7227?

As a low alloyed steel does the 1.7227 (here in its annealed condition) need the alloyed chromium and molybdenum to elevate its strength and hardenability. The added sulphur gives this steel grade a better machinability. Its chromium content makes sure that this heat treatable steel can be hardened through while the added molybdenum offers an even strength and hardness.

The combination of mechanical properties and the machinability make this steel grade a good choice for many applications in many industries.

Properties

Heat treatable steel 1.7227 also known as the 42CrMoS4 is a low alloyed chromium-molybdenum-steel. This steel grade is characterised by its high strength, good toughness and hardenability. It can be used for machine and tool construction and many other industries due to the former meantioned properties.

- Excellent wear resistance

- Excellent stress resistance

- Improved machinability

- High hardness

- High toughness

- Nitridable

- EMD machinable

- Difficult to weld

Applications

The 1.7227 is due to its high hardness and high toughness very versatile.

Heat treatable steel 1.7227 can be used for the following applications:

- Mandrels

- Flanges

- Collets

- Bending dies

- Crankshafts

- Clutch parts

- Forming rolls

- Short run stamping dies

- Mechanical engineering

- Machine parts

- Axes

- Knuckles

- Connecting rods

- Crankshafts

- Gear shafts

- Pinions

- Gears

- Bandages

- Base plates

- Assembling parts

1.7227 Standard values

Chemical composition:

| C | Si | Mn | P | S | Cr | Mo |

|---|---|---|---|---|---|---|

| 0.38 - 0.45 | 0 - 0.4 | 0.6 - 0.9 | 0.0 - 0.035 | 0.02 - 0.04 | 0.9 - 1.2 | 0.15 - 0.3 |

Chemical designation:

42CrMoS4

Working hardness:

approx. 27-48 HRC

Delivery condition:

max. 217 HB

1.7227 Physical properties

What group of steel does the 1.7227 belong to?

- Heat-treatable steel

- Cold work steel

Is the 1.7227 a stainless steel?

Even with a chromium and molbdenum content the 1.7227 is not a classic stainless steel as the classic 10,5% chromium stainless steel- It belongs to the group of high quality structural steel.

Is the 1.7227 corrosion resistant?

No the 1.7227 is not corrosion resistant. To be classified as a stainless steel the grade has to have a chromium content of at least 10,5 %. The 1.7227 has only got a massfraction of 0,9 – 1,2 % of chromium.

Is the 1.7227 magnetisable?

The heat-treatable steel 1.7227 is magnetisable and magnetic clamping can be used for machining, milling and grinding for example.

1.7227 Wear resistance

On a scale where 1 is low and 6 is high the 1.7227 receives a 3 for its wear resistance.

1.7227 Technical properties

Is the 1.7227 a knife steel?

When producing a knife with the 1.7227 corrosion resistance, hardness as well as wear resistance should be a focus. Though it is possible to make a knife with this material gade it is not usually used to manufacture knives.

1.7227 Working hardness

The working hardness for the 1.7227 is in the range of 27 – 48 HRC.

1.7227 Density

At room temperature the density for the 1.727 is at ,85 g/cm3.

1.7227 Tensile strength

The tensile strength for the 1.7227 is at max. 900 N/mm2. The tensile strength indicates the maximum load capacity. To obtain this information, a tensile test is carried out to determine how much force is required to elongate or stretch a sample before it breaks.

1.7227 Machinability

On a scale the 1.7227 receives a 5 for its machinabilty on a scale where 1 is low and 6 is high.

1.7227 Yield strength

The yield strength for the 1.7227 is at approx.655 N/mm2. It indicates how much stress can be applied before a material undergoes plastic deformation. Beyond this point, the material will not return to its original shape when the stress is removed, but will remain deformed or even break.

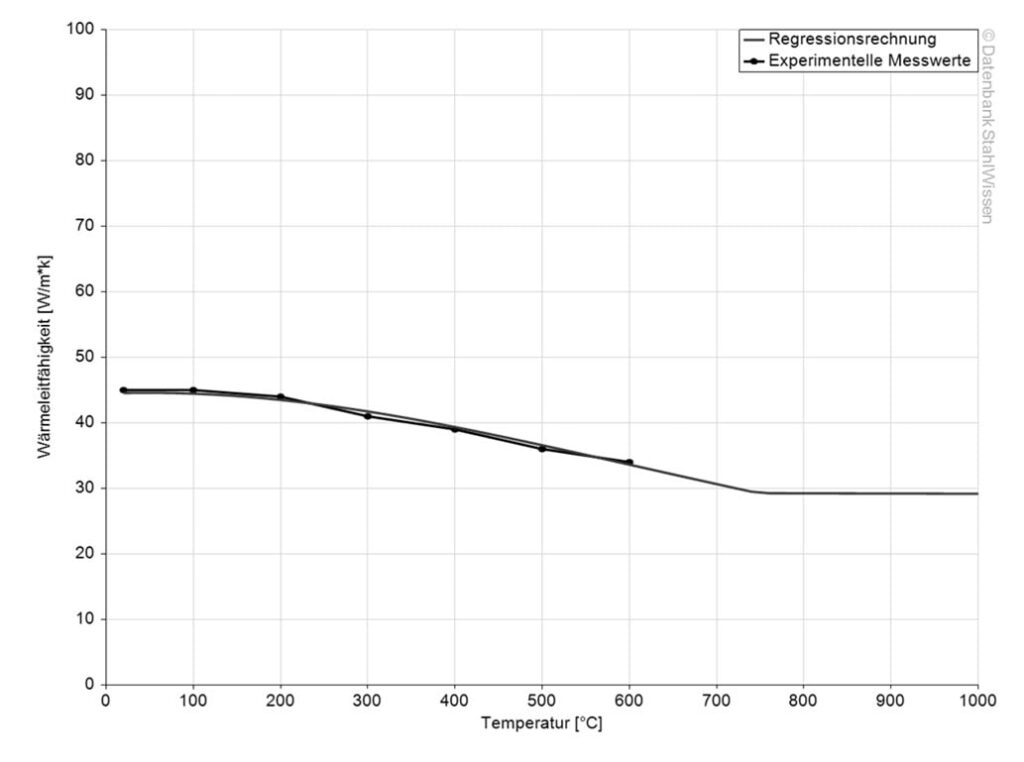

1.7227 Heat conductivity

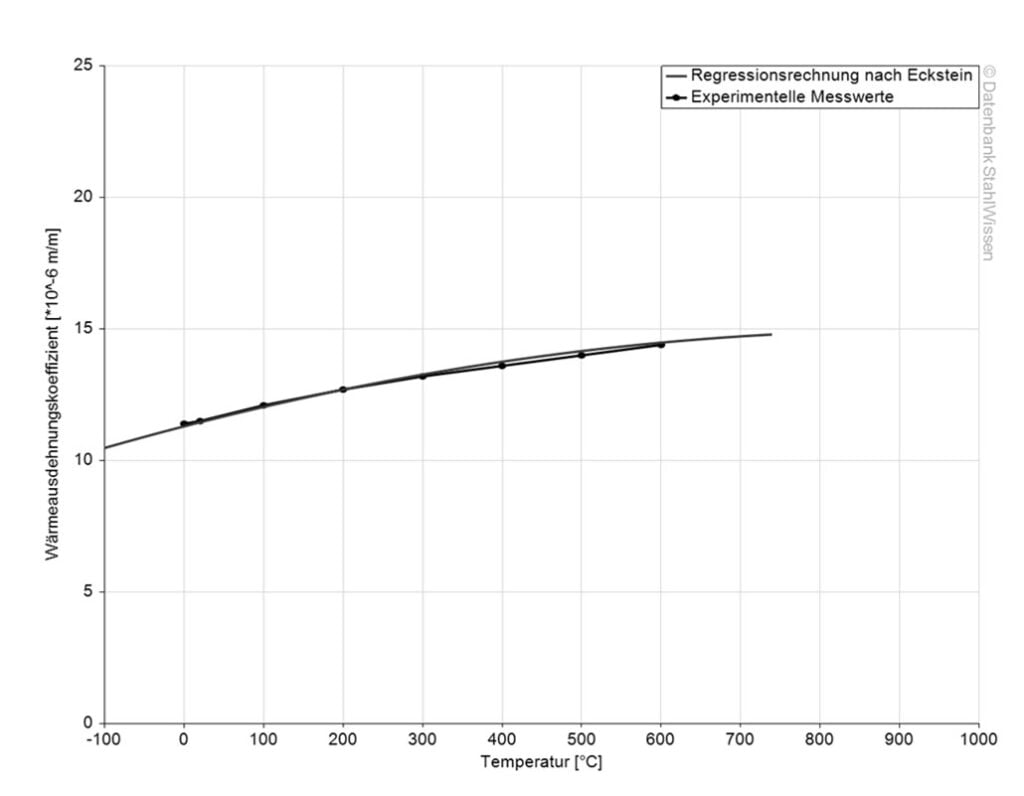

1.7227 Thermal expansion coefficient

The coefficient of thermal expansion indicates how much the material can expand or contract when the temperature changes. This is very important information, especially when working with high temperatures or when there are significant temperature fluctuations during use.

Medium thermal expansion coefficient

Value 10-6m/(m*K)

At a temeprature of

11.1

20 – 100 °C

12.1

20 – 200 °C

12.9

20 – 300 °C

13.5

20 – 400 °C

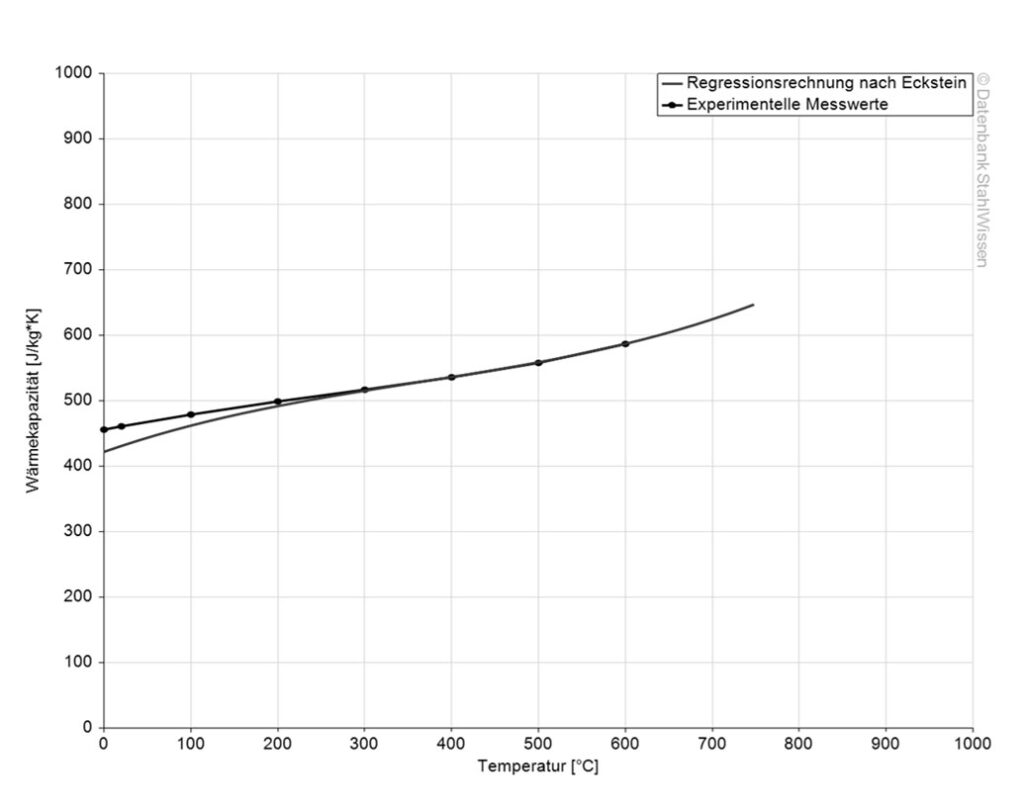

1.7227 Specific heat capacityt

The value of the specific heat capacity shows how much heat is needed to heat a specific amount of material by 1 Kelvin.

1.7227 Specific electrical resistance

The following table shows the specific electrical resistance. Electrical conductivity is the reciprocal of electrical resistivity.

Table of the specific electrical resistivity

Value (Ohm*mm²)/m

At a temperature of

0.19

20 °C

DUE TO ADDED SULPHUR – BS 709 M 40!

1.7227 Procedure

1.7227 Heat treatment

The 1.7227 material can be heated to 860 °C and quenched in oil. The 1.7227 material can achieve a good range of properties through normalising and tempering.

1.7227 Annealing

Heat the workpieces evenly to a temperature 680 – 720 °C and follow this up with a slow cooling down in the furnace to reach a hardness of approx. 217 HB.

1.7227 Stress relieving

The 1.7227 should be heated to a temperture of 593 – 705 °C and held for 2 hours at that temperature. After it can be cooled down in air.

1.7227 Normailsing

This matrial grade can be normalised befor it is hardened. For that it is heated to a temperature of 840 – 880 °C and cooled in air after.

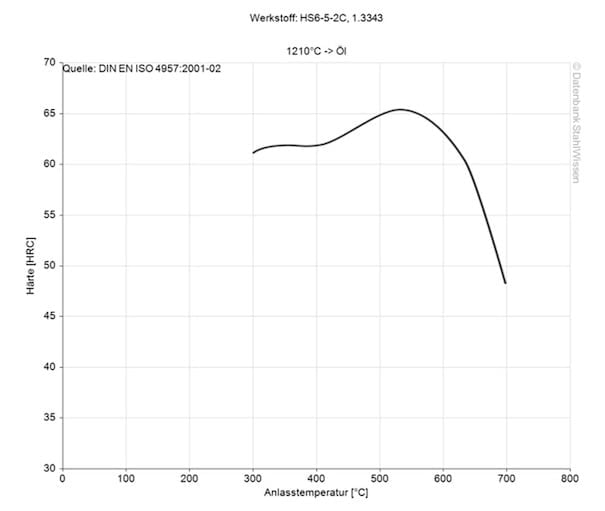

1.7227 Tempering

The higher the tempering temperature, the softer and more ductile the 1.7227 becomes. In general, hardness and ductility are determined by tempering the material. The higher the ductility, the lower the hardness, and vice versa. Apart from the advantage of giving the steel the desired and required properties, the material can be made stress-free, making it less prone to cracking and giving it better deformation behaviour due to tempering.

1.7227 Tempering temperature

The 1.7227 can be tempered at temperatures of 540 – 680 °C depending on hardness and needed propeties. After tempering the material should be cooled in air.

1.7227 Hardening

For hardening the 1.7227 should be heated slowly and evenly to 820 – 860 °C and after depending on size and complexity of the workpiece be quenched in water or oil. After quenching the possible working hardness is between 27 – 48 HRC.

1.7227 Quenching

The 1.7227 can be quenched in oil to room temperature and should be tempered straight away after.

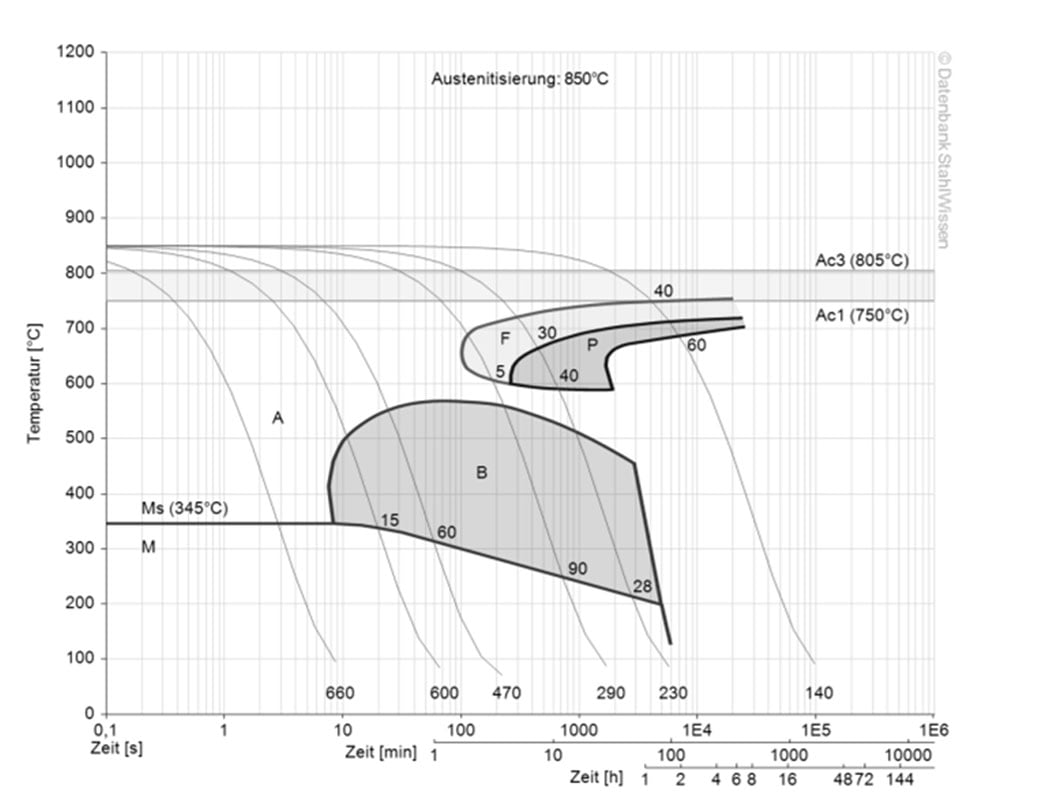

1.7227 Continous TTT-diagram

This diagram shows mirco changes over time at different temperatures. This can be important during heat treatment as it provides information about the optimal conditions for processes such as hardening, annealing and normalising.

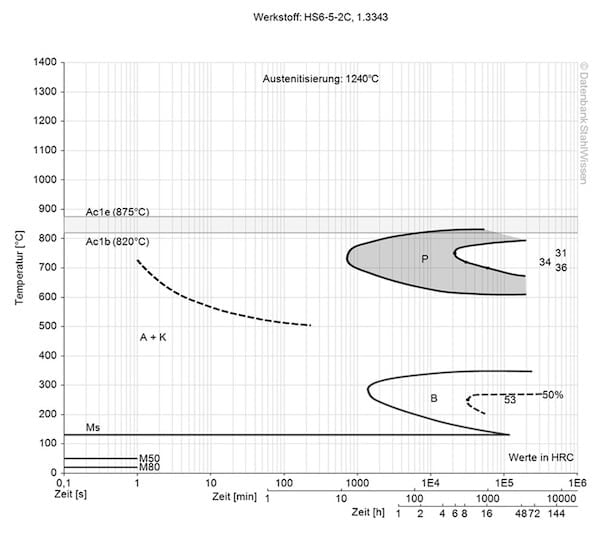

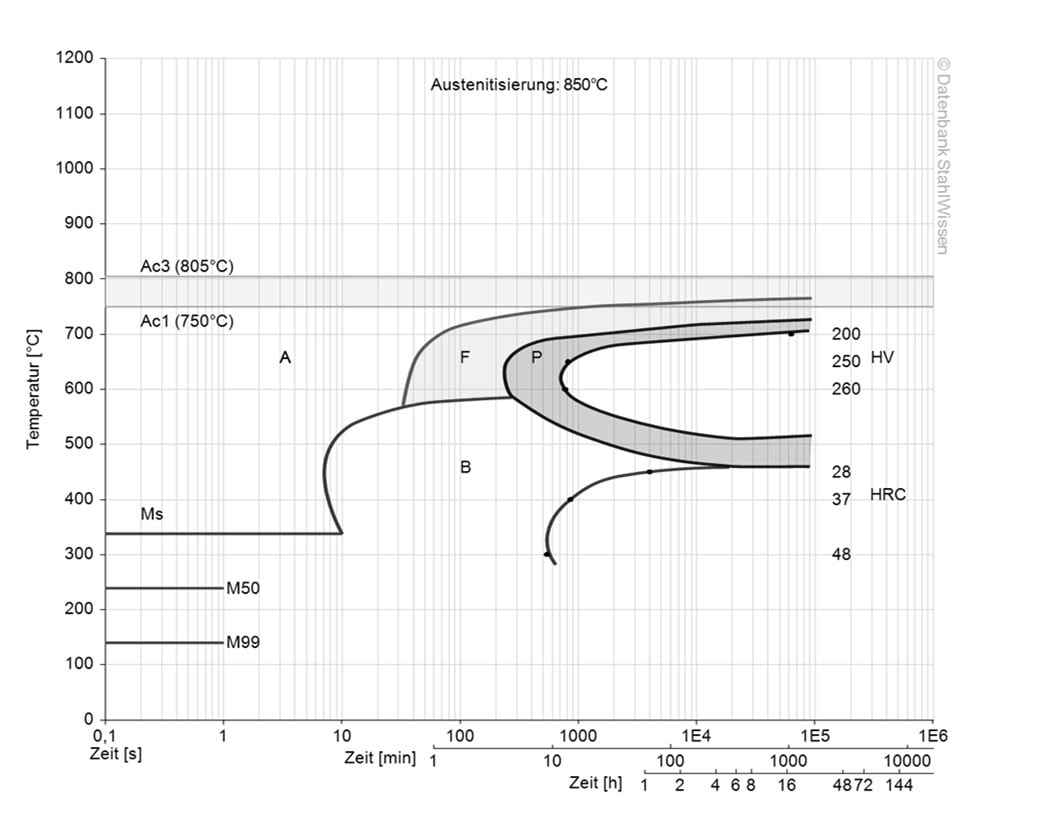

1.7227 Isothermal TTT-diagram

This diagram shows the structural changes at the micro level over time at a constant temperature. It shows at what temperature and after what time different phases, e.g. perlite, martensite or bainite, begin to form.

1.7227 Surface treatment

1.7227 Nitriding

The 1.7227 can be nitrided to give it a higher surface hardness. When nitriding nitrogen is diffused into the surface of the matrial to give it a harder surface and/or an improved corrosion resistance.

1.7227 Processing

After the heat treatment the 1.7227 has a microstructure needed for this material grade to be machined better.

1.7227 Electrical Discharge Machining (EDM)

It is possible to EDM this grade of steel in its annealed and hardened condition. After EDM, the recast layer, a thin white layer, should be removed by grinding and polishing for example, otherwise it may affect its service life and the performance of the workpieces.

1.7227 Forging

The 1.7227 can be forged in a temperature range of 900 – 1000 °C followed by a cooling down in still air or sand.